If all continues as expected the saga of not just the fix, but the fix of the fix, for the troubled Millennium Tower in San Francisco may be over by the end of September. The team for the revised perimeter pile upgrade—intended to stem and recover some of the settlement and tilt of the 645-ft-tall tower—reached a milestone last week. Crews successfully completed the initial stage of the transfer of loads from the residential condominium—which has been settling since its completion in 2009—to six new piles to bedrock installed along one side of the building.

“Our expectation was that this first small stage of load transfer would slow substantially, if not stop, the already recently reduced rates of settlement and tilting that has been occurring,” Ronald O. Hamburger, the consulting principal with Simpson Gumpertz & Heger (SGH) who is the engineer-of-record for the upgrade, wrote in a Jan. 29 progress report to the board of the Millennium Tower Association. “Preliminary data shows this has been successful and exceeded the engineering team’s projections.”

Voluntary Upgrade

The voluntary upgrade involves transferring a portion of the building weight to bedrock from the existing foundation system via 18 new piles to bedrock. The fix, likened to putting a bumper jack next to a flat tire, relies on drilling and jacking the 18 concrete piles—socketed more than 30 ft into the bedrock that starts 220 ft below grade—under the sidewalks along Mission and Fremont streets. The piles support a new mat section, known as a collar, that ties the existing mat to the new piles.

Over time the building had tilted to the west about 28 in. and to the north about 12 in. And it had settled about 18 in., according to Hamburger. “John Egan’s best estimate of tilt recovery, following the final stage of load transfer, is 4 inches west-to-east and 3 inches north-to-south," he adds. Egan is the upgrade’s geotechnical engineer-of-record.

During the incremental and synchronous jacking over the course of last week, the building recovered a part of the accumulated tilting, both to the north and west, and raised up slightly, said Hamburger in the report.

The jacking operation "recovered about 1/2 in. of tilt to the west and 1/8 in. of tilt to the north," Hamburger told ENR. "The whole building raised up about 0.1 in.," he says, adding, "you can't see the tilt or the recovery."

The 25-ft-deep trench excavation for the collar under the sidewalk on Mission Street also helped with the recovery by removing 1,000 tons of soil, says Hamburger. The removal of another 2,500 tons of soil on Fremont Street will also help, he adds.

So far, workers jacked approximately 1,500 tons, or about 1.5% of the building's weight, onto the six new piles in the trench. The goal is to transfer 17% of the total building load to the 18 new piles, says Hamburger.

In the progress report, Hamburger explained that the purpose of the first stage of loading was to stabilize the building during the remaining construction, which includes the Fremont trench and casting the second collar to tie in the 12 piles under the sidewalk there.

The second jacking operation, likely to take place in June once the Fremont collar cures, will load 500 kips on each of the 12 piles along Fremont. A third and final jacking operation will load all 18 piles to 1,000 kips, says Hamburger.

Six Months of Scrutiny

The revised upgrade consists of the 18 piles to bedrock, all of which were installed last year, rather than the original 52. Last August, after more than six months of scrutiny, the San Francisco Department of Building Inspection issued a revised building permit #202107194668 for the revamped perimeter pile scheme. The entire installation and load transfer operation permit was approved and issued upon review by DBI and also the city's independent engineering design review team (ERDT), according to Patrick Hannan, DBI's communications director.

Hamburger says the revised permit did not specifically address the phased load transfer. "The city [considers] that means and methods" and doesn't care about the order as long as all the load is transferred by the end of the project, he adds.

The revised scheme is a consequence of problems with the initial pile work, executed by Legacy Foundations, a division of Shimmick Construction Co. Inc., which is the prime contractor. Hamburger halted the repairs in August 2021, after the voluntary fix, designed to stem the total of about 18 in. of settlement, had instead accelerated it, causing a 1-in. increase. SGH, Shimmick and a team of experts then revamped the pile installation work itself to stem that problem.

Following that, SGH re-engineered the perimeter pile upgrade scheme to reduce the number of piles to 18. In June, the city's review team scrutinizing the upgrade signed off on the 18-pile plan, saying the reduced scope would accomplish the original project objectives of arresting the horizontal and vertical movement, as well as reducing a portion of the building’s current tilt over time.

Synchronous Jacking

The first stage of the synchronous jacking took place from Jan. 23-27. Crews installed the pile jacks the week before in the 15-ft-deep trench on Mission. The only part of the operation visible from the street was the hydraulic power unit for the jacks.

"The project sponsor has been in constant contact with EDRT and DBI and has provided daily reports of the site monitoring data during the partial load transfer," says Hannan.

"The building remains occupied during the jacking and during the entire pile upgrade," adds Hamburger. Sidewalks along Fremont and Mission remain closed.

Each jack sits on top of a pile. "There is a W24 steel load beam on top of each jack," he adds.

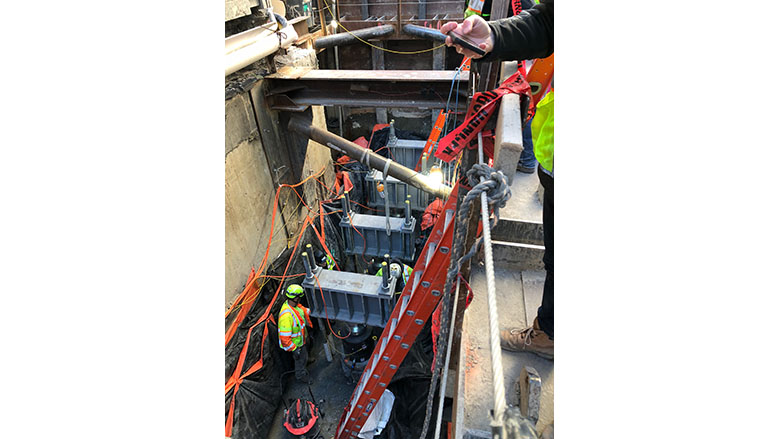

Workers in the trench along Mission Street prepare the piles and jacks for the initial load transfer operation, part of the perimeter pile upgrade for the 645-ft-tall Millennium Tower.

Workers in the trench along Mission Street prepare the piles and jacks for the initial load transfer operation, part of the perimeter pile upgrade for the 645-ft-tall Millennium Tower.Photo by Ronald O. Hamburger

The load beam is connected to the collar with threaded rods. When pressure is applied, the jack pushes up on the load beam and down on the pile. There is a casing around each pile to isolate it from the collar so that the pile can compress when loaded. The rods on the load beam hold the beam in place and transfer the load back to the mat.

Workers loaded each pile to 500 kips in 100 kip increments over the five days. Crack gauges were installed. And each day, surveys were done before and after the jacking to measure movement.

The loading took 10 minutes. The surveys took a couple hours each.

"There was minor movement of 0.1 millimeter," says Hamburger. "Nothing of concern and nothing visible."

During the operation, the upgrade team worked onsite with representatives of the engineering design review team, Dan Brown Associates—the geotechnical engineer engaged to monitor the project and Shimmick. The project sponsor has been in close contact with EDRT and DBI and has provided daily reports of the site monitoring data during the partial load transfer, according to Hannan.

The engineering and management team will continue to monitor the building as work continues, adds Hamburger.

Moving forward, crews will soon begin the trench excavation along Fremont Street for the collar and to enable them to tie in the 12 additional piles under the sidewalk. When the operation is complete, crews will build a vault around the pile heads, back-fill soil into the excavation and restore the sidewalk, landscaping and building facade.

Editor's note: This article was updated on Feb. 7.

Post a comment to this article

Report Abusive Comment