Walking to work one November morning, structural engineer Chris Jeseritz was buoyed by a Nelson Mandela quotation on a digital sign on the side of a Seattle office tower: “A winner is a dreamer who never gives up.”

The quote resonated with Jeseritz. His firm, PCS Structural Solutions, is committed to pursuing an extremely ambitious sustainability goal, which even Jeseritz considers a near-impossible but worthy pursuit. PCS has pledged to eliminate embodied carbon in all its projects by 2050. “The subject of sustainability is so important,” says Jeseritz, PCS’ sustainability team leader.

PCS isn’t alone in its quixotic pursuit of zero-carbon structures. It is one of 101 structural firms that have, to date, become signatories of the Structural Engineers 2050 Commitment Program, an initiative of the Structural Engineering Institute of the American Society of Civil Engineers.

The SE 2050 program is a response to the Carbon Leadership Forum’s 2050 Challenge, which states that “all structural engineers shall understand, reduce and ultimately eliminate embodied carbon in their projects by 2050.”

“We know this is an insane goal but we have no choice,” says Mike Gryniuk, a principal at LeMessurier and chair of the two-year-old SE 2050 program. “If we don’t start pulling this community together and go after a challenging goal, we are going to have some serious societal issues,” regarding global warming, he asserts.

Not everyone thinks the challenge is an impossible one. Jordan Woodson, an associate at SE 2050 signatory Arup, thinks it is “achievable, but will take buy-in from more than the structural engineers.”

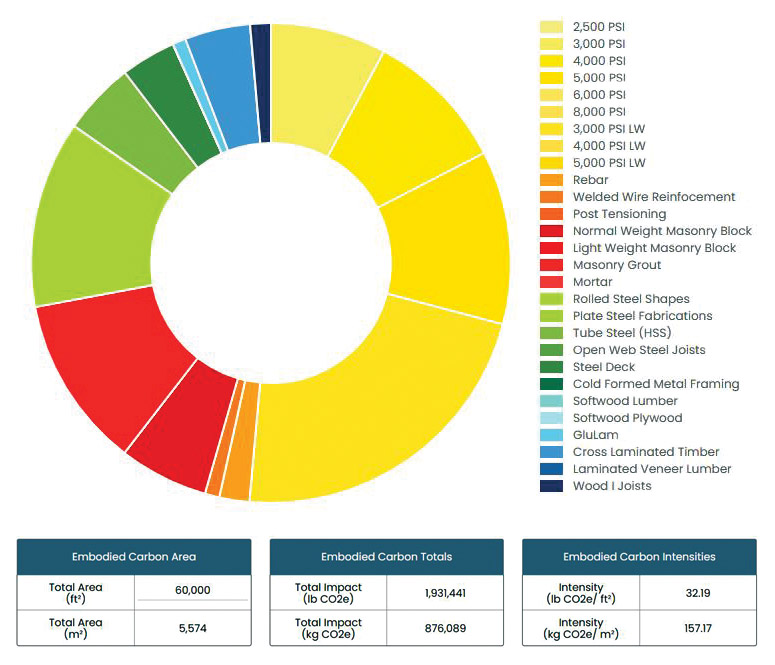

Free digital tool from SE 2050 allows users to do quick calculations of embodied carbon intensities of structural materials by building area.

*Click on the graphic for greater detail

Success relies on many factors, such as the greening of the power grid, in addition to support from owners, developers, architects, contractors, material suppliers, fabricators and manufacturers.

Structural engineers are not blind to the obstacles to the proliferation of zero-carbon building structures. These include the construction industry’s inertia, resistance to change, fear of taking risks and fragmentation. “We’re knocking down the silos of a traditionally segmented industry and building a tent around sustainability,” says Luke Lombardi, senior sustainability consultant with signatory Buro Happold.

One problem is that “there’s often a misperception of what low-carbon construction means,” says Donald W. Davies, president of SE 2050 signatory Magnusson Klemencic Associates (MKA). “Many think it is more expensive and takes longer,” which is not always the case, he adds.

SE 2050’s interim goal is to halve carbon content by 2030. Some signatories are already reducing carbon footprints by 10% to 20%—or more. On LeMessurier’s Boston University Center for Computing & Data Sciences—just completed—the reductions in individual select concrete components varied between 15% and 35%, with reductions in portland cement content between 40% and 70%, says Gryniuk.

Still, the LeMessurier numbers are an exception. The structural design community as a whole has yet to make a dent in structural embodied carbon, which, according to Gryniuk, accounts for about 40% of the total embodied carbon in a building.

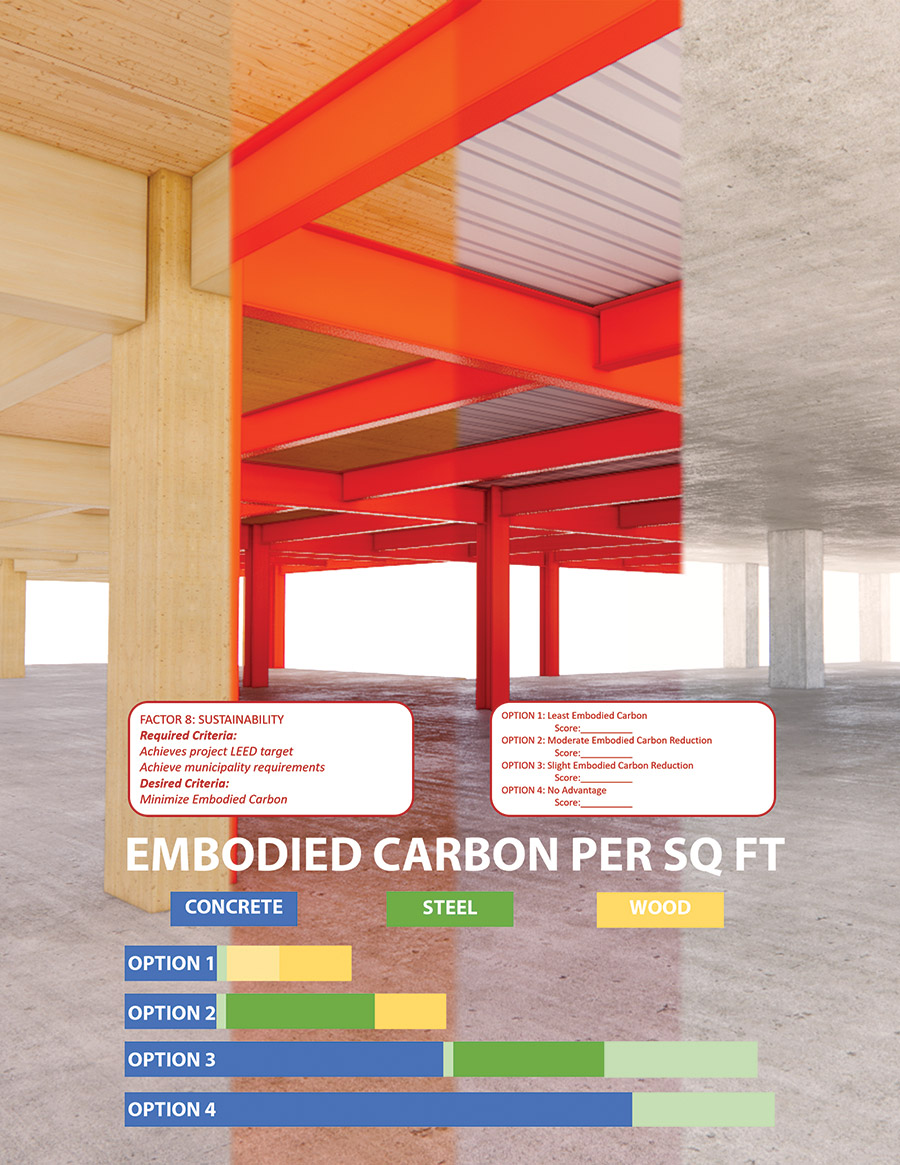

CHOOSING BY ADVANTAGES EXAMPLE

Four possibilities (from left)

Opt. 1 All mass timber structure

Opt. 2 Hybrid steel frame with mass timber floors

Opt. 3 Steel frame with composite slab on deck

Opt. 4 Cast-in-place reinforced concrete

Graphic courtesy Odeh Engineers

*Click on the graphic for greater detail

“As a profession, we’re still in the ‘understand’ phase’” of embodied carbon reduction, says Jeseritz.

“We need to educate an entire industry never taught this in school,” adds Davies. “And we need to create standards, so we are operating from a common platform.”

Until recently, operational carbon—greenhouse gases (GHGs) emitted during building operations—was the focus of the green-building movement. Structural engineers felt left out.

No more. The SE 2050 signatories—many direct competitors—see a golden opportunity for the profession to take the lead on sustainable structures. Toward this, they are working together on several fronts, promoting SE 2050’s mission “to transform the practice of structural engineering in a way that is holistic, firm-wide, project-based and data driven.” And they are doing this as volunteers.

Embodied carbon is defined as GHG emissions—mostly carbon dioxide—arising from the mining, manufacturing, transportation, installation, maintenance and disposal of building materials and products, expressed as global warming potential.

GWP is set through a whole-building life-cycle assessment—a systematic way of compiling and analyzing all the inputs, outputs and potential environmental impacts of a building. Product or material LCAs produce “ingredient labels,” called environmental product declarations (EPDs), that list GWPs.

The higher the number, the greater the GWP. For example, in 2021, according to the Portland Cement Association, the 100-year global warming potential of carbon-intensive cement was 922 kg CO2e, which means CO2 plus equivalent or similar gases. In 2016, it was 1,040 kg CO2e.

Movement is Gaining Momentum

The embodied carbon reduction movement is gaining momentum in the U.S. Recent laws and policy incentives at all levels of government, such as the Dec. 15 passage in the New Jersey legislature of a first-of-its-kind bill that provides a tax credit for use of low-carbon concrete, are fueling the movement. So is a large federal funding spike addressing embodied carbon and supporting the development of EPDs. And there are federal programs underway. For example, the Energy Dept.’s Harnessing Emissions into Structures Taking Inputs from the Atmosphere (HESTIA) initiative has funded 18 projects that are developing technologies for sequestering carbon in structures.

There are new technologies and products that reduce embodied carbon in materials, especially concrete—long the low-hanging fruit of carbon reduction due to the CO2 released during cement production. Some cleaner cements, among them calcined clay limestone cement and portland limestone cement, show great promise for scaling up the greening of concrete, say concrete specialists.

1550 on the Green, about to top out, is the first project in the city to require environmental product declarations for its concrete mixes.

Photo courtesy Skanska

For structural engineers, there is carbon-reduction support, in addition to SE 2050 and the 13-year-old Carbon Leadership Forum, which issued the 2050 Challenge in 2019. NEU, the American Concrete Institute’s Center of Excellence for Carbon Neutral Concrete, and the National Council of Structural Engineers Association’s sustainability initiative may be the newest on the block.

NCSEA formed a sustainable design committee about three years ago to assist state SEAs that wanted to form sustainable design committees. The idea is “to take all the great work at the national level and filter it down to practicing engineers at the local level,” says Kelly Roberts, a principal at SE 2050 signatory Walter P Moore (WPM) and founding chair of the NCSEA committee.

The National Ready Mixed Concrete Association, the American Institute of Steel Construction and other material-focused groups offer webinars and guidance. And the U.S. Green Building Council’s LEED certification system now offers credits for carbon reduction.

Some influential owners and developers—including but not limited to the U.S. General Services Administration, Hines, Lendlease Americas, Skanska USA Commercial Development, Google, Microsoft, Amazon and various institutional owners—are pushing carbon reduction. In 2022, Hines issued a free Embodied Carbon Reduction Guide, developed with MKA.

Lower-carbon structures are changing building-team dynamics. “We onboard the structural engineer during conceptual design because carbon reduction is an interwoven cloth,” says Natalie Wheating, sustainability manager for Lendlease Americas’ development unit. “If you tug at one string, there are impacts on other elements,” even mechanical systems, she adds.

A design charrette at the start of the project can be beneficial to discuss and rank different structural options and their direct and indirect embodied carbon impacts, says Mark D. Webster, a senior consulting engineer with SE 2050 signatory Simpson Gumpertz & Heger.

SGH advises conducting a whole-building life-cycle assessment—which is an added cost—to vet the assumptions the team makes during the charrette.

SE 2050 member Odeh Engineers has adapted a decision-making method used in Lean construction, called choosing by advantages, to vet its carbon-reduction options.

For a mid-rise residential building in the Boston area, Odeh recently developed four structural schemes not traditionally used in New England, each containing a different level of carbon reduction: an all mass-timber structure, with glulam columns and beams and cross-laminated timber floors; a hybrid steel frame with CLT floors; a steel frame with a composite steel and concrete slab on deck; and a cast-in-place reinforced concrete structure.

“We had to describe the building systems completely, including the impact on the architecture and the MEP systems, to adequately capture the advantages of each option,” says David J. Odeh, a principal with the firm, now part of WSP.

Odeh invited the design team, the likely construction manager and the developer to convene during conceptual design and perform the choosing by advantages exercise, which, among many things, involves comparing constructibility, cost and local availability of materials.

Structural engineers generally agree the first step in carbon reduction in-house is to optimize the structural system—creating the most efficient column-grid layout —and minimize member sizes and material quantities.

“Design optimization moves the needle forward as much or more than material specifications,” says Benton Johnson, a principal with Skidmore Owings & Merrill, an SE 2050 signatory.

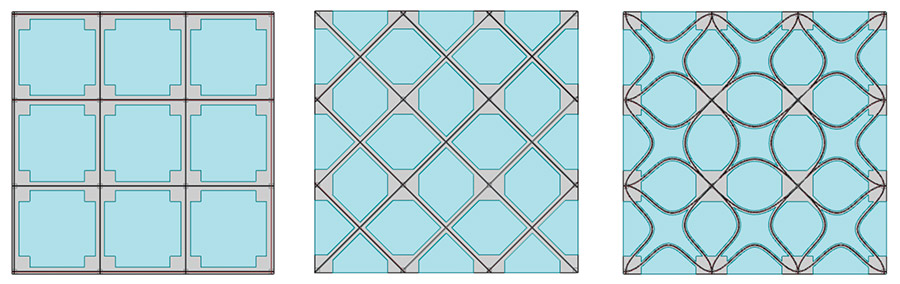

Research shows concrete slab post-tensioning, studied in orthogonal, diagonal and curved layouts, can reduce carbon by 30%.

Graphics courtesy Lera

MKA’s Davies advises engineers to “simplify load paths, use materials where they are most efficient and engineer waste out of the system.”

Material optimization comes next. Steel production in the U.S., where most of the structural shapes are made from 90% or more recycled material using electric-arc furnaces, is about as sustainable as it can be until mills convert to renewable power. “Steel is a more straightforward problem than concrete,” says Scott Schneider, co-lead of the structural engineering practice at Thornton Tomasetti, an SE 2050 signatory.

Others agree. “The most effective way to reduce the embodied carbon on a project is to reduce the volume of material in a floor slab,” says Richard Garlock, a partner with LERA Consulting Structural Engineers, an SE 2050 signatory.

For concrete elements, engineers recommend specifying blended cements, requiring the use of supplementary cementitious materials and increasing the time required to achieve the required strength, where possible, as in the foundations. Any reduction in concrete’s portland cement concrete is “helpful,” even if you don’t attempt to quantify it, says Dirk Kestner, WPM’s director of sustainable design.

Engineers can tailor mix cure times and strengths to individual slabs, instead of the more typical one-size-fits-all spec for all floors. Contractor mockups during design may help vet new products, agree engineers, because low-cement mixes may cause placing, finishing and curing issues.

Post-tensioned Slabs Save Carbon

LERA has been studying post-tensioned slabs combined with a rarely used flat-plate deck technology called a voided biaxial slab system, which relies on permanent plastic bubble forms to create voids in the deck. LERA’s research shows that for spans between 25 ft and 30 ft, PT saves about 30% of the carbon in a conventional flat plate concrete structure. LERA also found that introducing orthogonal PT tendons with voided slabs saves 40% to 45% of the embodied carbon. Diagonal PT with voids saves upwards of 55%.

The Rob & Melani Walton Center for Planetary Health at Arizona State University, completed in 2021, used voided slabs for the first time in Arizona. Buro Happold introduced the idea for roughly 50% of the floors. The firm also wrote a performance spec for a 40% reduction in portland cement that McCarthy Building Cos., which self-performed concrete work, elected to meet using a 40% fly ash replacement, instead of 20%. The two-pronged attack reduced concrete by 1,300 cu yd and carbon by 40% over the initial design.

The choices came with risks and challenges, which McCarthy met. High fly-ash mixes are stickier, which can affect pumpability. And the local labor force had no experience with voided slabs, which require extra steps.

Performance-oriented specs are increasingly popular for carbon reduction. The spec includes a reduction target and, at times, requests the subs file EPDs during the project. Competitors for carbon reduction projects often vie for the work based on four performance metrics: quality, cost, schedule and reduced carbon, say engineers.

It’s not always that fluid. On Salesforce Tower Chicago, which will open in 2023, MKA wrote a performance-oriented spec and asked for concrete EPDs. There was immediate pushback from the contractor, which said the request for EPDs would cost $300,000 and add six months to the schedule, says Davies.

MKA persevered by educating the team, he adds. It turned out the EPD strategy added nothing to cost or schedule, says Davies, because the request set up a healthy competition among the subs vying for the job.

Not All Suppliers Have EPDs

Another snag is that in many cities—other than Seattle, San Francisco, Los Angeles and Chicago—not all suppliers have EPDs. Houston’s didn’t until the 28-story 1550 on the Green project, set to top out in January.

“We required EPDs” for the concrete mixes, says Kestner. Because of that, Cemex, 1550’s readymix supplier, has EPDs for its other projects in Houston, he adds.

For the 1550 project, developed by Skanska Commercial Development, WPM— working closely with contractor Skanska USA Building Cos.—reduced the slab thickness of the pan-formed system by 3/8 in. That saved roughly 700 cu yd of concrete over the project, says Kestner, which means roughly 70 fewer truckloads of concrete.

Kestner says the 1550 building is currently tracking a 10% embodied carbon reduction—the threshold to achieve three points in LEED’s building life-cycle impact reduction credit.

Structural carbon reduction may seem overwhelming. Davies’ advice to beginners: “You can’t manage what you don’t measure, so start there. The simple math: quantities x GWP/material = GWP of the project.”

SGH’s Webster advises newcomers to go to the SE 2050 website for free guidance and use of its digital embodied carbon calculating tool, ECOM, which stands for Embodied Carbon Order of Magnitude. All the engineer needs to do is estimate material quantities and plug them into the tool. “It’s wicked easy to use,” he says.

Another free digital tool, launched in 2019, is EC3—Building Transparency’s Embodied Carbon in Construction Calculator.

For engineers intimidated by the entire enterprise, Kestner offers six “easy” steps to carbon reduction:

1) Determine the bill of materials; 2) Input quantities into ECOM; 3) Identify hotspots with the most embodied carbon; 4) Review the design to determine opportunities for reduction of the hotspot materials; 5) Review the specs and the anticipated material supply chain by talking to potential suppliers, asking if they have product specific EPDs or if they have lower embodied carbon options; 6) Update the design and iterate.

Cary Kopczynski, CEO of the SE 2050 signatory engineer that bears his name, likens the SE 2050 Challenge to President John F. Kennedy’s commitment, in the early 60s, for the U.S. to travel safely to the moon and back by the end of that decade. “The aerospace sector rose to the occasion and met the challenge,” says Kopczynski.

Webster adds, “Even if we don’t meet the 2050 Challenge, we need to try as hard as we can, because every reduction will make a difference.

“It is best to stay positive and optimistic, even in the face of daunting hurdles,” he says. Regarding climate change, “action is the best antidote to despair.”

Post a comment to this article

Report Abusive Comment