Angelle Bergeron/ENR Pumps and a sluice gate are safety measures for load-testing levee.

|

For the first time, the U.S. Army Corps of Engineers is conducting a site-specific load test on an active piece of a flood protection system. It is loading a heavily instrumented, 150-ft-long section of levee and I-wall in New Orleans with the equivalent of a storm flood. The Corps is trying to determine if it can safely increase the maximum water elevation in one of New Orleans’ main outfall canals. Officials say the experience gained may pave the way for real-time testing on active floodwall and levee structures elsewhere in the nation.

“The Corps is a learning organization....The lessons learned and the after-action review from this test will be shared throughout the Corps of Engineers,” says Major Nicholas Nazarko, chief of staff for the Hurricane Protection Office and officer-in-charge/project manager for safety on the test. “This could have applicability anywhere there is an I-wall,” he says.

The $4-million budget for the test includes about $2.6 million for construction, Nazarko says.

Pat Conroy, chief of the geotechnical design section of the Corps’ St. Louis District, which is serving as technical lead, says he has done many load tests in his career but never on an active flood protection system. “This is real life, real time, real world,” he says.

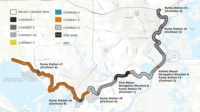

The Corps proposed the test in April to determine if the safe-water elevation in the London Avenue outfall canal may be increased from +4.0 ft to +5.0 ft.

“It’s only a foot, but it increases the amount of water the Sewerage & Water Board can dump into this canal by about 30%,” says Nazarco. “That will be a huge comfort to residents if a hurricane heads toward New Orleans.”

The test also will help the Corps decide if a full-canal load test is needed. “This modeling scenario gets some real-world reaction data that can be used to calibrate the models and determine, without reducing safety, if we can go to 5 ft,” Nazarko says.

The London Avenue Canal’s +4.0-ft safe-water-elevation limit, which the Corps suspects is overly conservative, was set to avoid straining the I-walls and levees that line it. Those structures failed in two places and were stressed in many others by the high waters of Katrina. The mouth of the canal, as well as the mouths of two other outfall canals whose levees and floodwalls are of similar construction but in stronger soils, have since been fitted with temporary gates at their Lake Pontchartrain ends to keep storm surge from entering. All of the canals have safe-water limitations, but the London Avenue Canal’s are lowest. If the temporary gates must be closed during a storm, the portion of the city’s stormwater system that discharges into it will have to restrict pumping, which would lead to widespread flooding of homes.

Angelle Bergeron/ENR Inclinometers, tilt meters, piezometers and prisms stud the structure.

|

The test site was chosen because the geology is similar to that beneath the locations that failed during Hurricane Katrina, Nazarko says. The levee is built of compacted clay on top of a layer of marsh, which is over a layer of sand that extends to a depth of about 45 ft. To prepare for the test, joint-venture contractor Allen Wright Enterprises Inc./Hamp’s Construction LLC, New Orleans, built a three-sided cofferdam 35 ft inside the canal to isolate a 150-ft length of levee and I-wall. Sheetpiles are driven 48 ft deep into a clay layer “to more effectively isolate the reaction of the wall,” Nazarko says. The Corps is filling the cofferdam with water in 6-in. lifts and monitoring the load on the wall and levee.

The London Avenue Canal breaches are believed to have occurred when the water load made the wall deflect, opening a crack between the clay and the long sheetpiles that are capped by the concrete I-wall, Nazarko says. Seepage down that crack may have reached the sand layer and then undermined the wall. Another possibility is that the sand strata was accessed through the floor of the canal and water forced its way under the levee and undermined it by that route. To isolate that possibility and test the crack theory, the Corps has placed bentonite on the floor of the canal within the cofferdam to create a seal.

For a second phase of tests, the Corps will drive 30 No. 10 plastic slot pipes, separated by a solid riser, along the edge of the cofferdam to create direct contact with the underlying sand strata and mimic a seepage-inducing failure through the floor of the canal. “Inserting the slotted pipes will ensure that the water in the...

Post a comment to this article

Report Abusive Comment