Nadine M. Post / ENR Webcor’s Plue, left, MKA’s Klemencic and Johansson, and Bovis senior project manager Nori Mizushima (front) teamed to achieve a three-day-per-floor cycle.

|

Structural engineer Ron Klemencic had extra reasons for gratitude during the 2005 Thanksgiving season. After hitting his head against the wall on and off for more than three years, he finally received stamps of approval for the first two performance-based seismic design high-rises in earthquake prone San Francisco. PSD can cost less, improve design and ease construction.

Word about the 38- and 43-story Infinity towers came the last week of November, followed by news about the 64-story One Rincon Hill (ORH) in early December. “I was elated both times,” says Klemencic, president of Magnusson Klemencic Associates, Seattle. “It was two years of blood sweat and tears on [the Infinity] before we even initiated Rincon Hill.” That review took a year, twice the norm for San Francisco towers.

The city’s approval marked the beginning of the end of a logjam in big California cities for performance seismic design (PSD) of buildings taller than 240 ft. “People are going to be doing this left-handed at 100 mph in five years thanks to Ron...,” predicts one prominent San Francisco architect who declines to be identified.

Bovis Lend Lease Hoist will remain to feed upper floors during phased move-in starting next month.

|

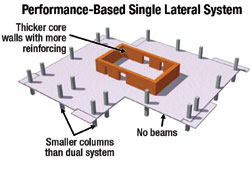

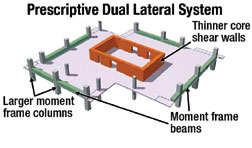

The approach is a way to meet the intent of the code’s prescriptive provisions by using a single framing system instead of a costlier and “clunkier” dual system to resist lateral loads. But some cities are cautious in allowing PSD because it requires extreme engineering.

The 590-ft-tall ORH is the higher profile of the two cutting-edge projects, and not just because it is taller and sits on a hill nudged up against the Bay Bridge approach. The nod from the city unlocked the door not simply to PSD in California but to the tallest “performance” skyscraper in the U.S. ORH is also the tallest high-rise to contain buckling-restrained braces and the first to use BRBs as outriggers. The slender tower is the first residential building in the U.S. to have a liquid tuned mass damper to reduce sway to acceptable comfort levels, says the engineer.

There’s more. PSD saved $5 per sq ft and allowed Webcor Concrete, Hayward, Calif., to achieve a three-day cycle—the norm is five—on typical tower floors. That’s a West Coast speed record for high-rise concrete work.

The general contractor is especially proud that the short cycle was also achieved on the upper system of BRBs. (The lower system met a five-day cycle, as planned.) “It’s pretty amazing,” says Tim Dean, structural project manager in the local office of Bovis Lend Lease Inc.

Webcor Spandrel-beam-free perimeter eases flying form construction, saves money.

|

The single-frame PSD, engineered using sophisticated computer simulations and analysis, consists of a ductile concrete core with the supplemental outriggers and post-tensioned flat slabs. It has no spandrel beams because it has no back-up perimeter moment frame, as required under prescriptive code provisions.

For the 362-unit condo’s developer, that’s a selling point. “Being able to remove the moment frame and use floor-to-ceiling glass was a key issue to differentiate the building in the marketplace,” says Jeffrey S. Sell, vice president of the local Project Management Advisors Inc. PMA represents ORH’s developer, Urban West Associates, San Diego.

But there was a hitch. “There were risks associated with the design because the process had never been approved in San Francisco,” says Sell.

Not only that, Klemencic made sure Urban West knew all about the ongoing excruciating peer review process for the 350-ft and 400-ft Infinity towers. Urban West “had no assurances about whether ORH project would be delayed in the review, and if so, at what cost, says Sell.

After weighing benefits and risks, the developer decided to commit to MKA’s scheme at a project kickoff meeting in July 2004. But it had a strategy for success. MKA knew the structural design would get picked to pieces on all fronts during the peer review. So it was critical to keep the structural system very simple in order to keep the architecture simple.

Magnusson Klemencic Associates

|

Repetition and consistency ruled to minimize reviewers’ questions. “The design team as a whole had to get religion about the core, not because we couldn’t change it but because we wanted to fight only one big battle in the peer review process,” says Klemencic.

That had ramifications for the architect and its subconsultants. The core and it contents, including elevators, stairs, electric rooms and service areas, the typical floor plate and the floor-to-floor height had to be placed, sized and frozen four months earlier than usual. Lobby design had to be locked in eight months early. At ORH, “the concrete shown in the architect’s plans never changed from Aug. 15, 2004,” says Chris Pemberton, a vice president in the local office of architect Solomon Cordwell Buenz.

Magnusson Klemencic Associates |

The strategy worked. Peer review went “incredibly smoothly” with “technical issues resolved quickly to everyone’s satisfaction,” says Ronald O. Hamburger, senior principal in the San Francisco office of Simpson Gumpertz & Heger, and the chair of the three-person panel.

Klemencic gives the Infinity some credit for that. “Infinity took the lumps in terms of technical arguments,” Klemencic says. “Rincon Hill definitely benefited from that.”

Webcor

|

In the end, the ORH team met its schedule goals. Construction of typical tower floors 8-60 started in July 2006. The building received a temporary certificate of occupancy for the first 20 floors on Jan. 4. Bovis expects a TCO for the next seven in a couple weeks. Condo owners are scheduled to begin a phased move-in next month and full completion is set for the summer. “We are happy with the schedule,” says Peter Read, Bovis project director.

Owners like PSDs because they cost less. Architects like them because they offer more design freedom. Contractors like them because they are easier to build. And engineers like them because they can result in higher-quality structures.

For example, computer earthquake simulations revealed significant stress demands half way up the tower—a bowing effect rather than the anticipated swaying. MKA added mid-height shear and confinement rebar to give the frame additional strength and robustness. “This shows the value of PSD,” says...

Post a comment to this article

Report Abusive Comment