... a high level of precision, important due the tolerance requirements of the BRBs,” says Johansson.

| + click to enlarge |

|

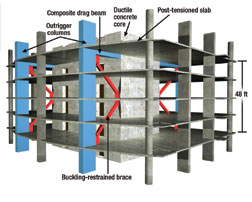

At the top and bottom of each system, composite drag elements consisting of steel-plate beams embedded in reinforced concrete connect outrigger columns to embedded steel in the core.

The MKA scheme both simplified and complicated construction. The absence of beams and the repetition made flying forms the choice for typical floors. But the core, more congested with rebar at the base, made things tougher there. That said, “We have nonperformance-based designs that have worse congestion,” says Chris Plue, a Webcor vice president.

Magnusson Klemencic Associates

|

Magnusson Klemencic Associates

|

BRBs, installed by TC Steel, Petaluma, Calif., also had their challenges. Erection tolerances at the connection plates were about 1⁄16 in. Alignment of embedded steel was critical to ensure proper fit. That meant careful coordination and cooperation among all structural trades. Continuous survey control was performed during concrete placement to ensure connection plates remained true and plumb, says Bovis.

Bovis says the key to the shorter cycle was careful coordination of the trades, separation of vertical and horizontal construction by keeping the core three levels ahead of the deck, and MKA’s PSD.

“MKA values their role in the speed of construction,” says Plue.

The short cycle resulted in earlier occupancy by two months compared with Webcor’s usual four-day cycle for a dual system. Webcor’s competitors confirm they know of no other West Coast tall building that has gone up this fast. But they also say ORH’s small floor plate helped.

Webcor took 10 floors to perfect the sequence. The tower’s first typical floor is level eight. Workers hit the three-day cycle at level 18.

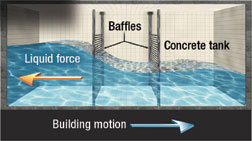

Magnusson Klemencic Associates Tuned Liquid-Mass Damper

|

Double work shifts helped. So did the 1,000-sq-ft, truss-supported flying table forms for the slabs. Each form took only 40 minutes to set, says Bovis. Webcor used two sets of truss-supported flyers—eight per floor. The flyers are hung off columns as opposed to bearing on floors. The system is more costly but eliminates reshores on the floors below. That kept them wide open for the follow-on trades to do their work.

Bovis says a big challenge with the aggressive schedule was keeping information flowing, especially to the design-build mechanical-electrical-plumbing and curtain wall systems. Coordination of these was only a few floors ahead of the structure’s construction. “Getting information out to all trades as soon as it was available was critical,” says Dean.

| + click to enlarge |

|

Magnusson Klemencic Associates One Rincon Hill is first U.S. tower to have a tuned liquid-mass damper.

|

Having worked out the shorter cycle at ORH, Webcor now is achieving it on the taller tower of the Infinity. The building is currently up 35 of 43 floors.

ORH’s phased occupancy, a first in the city for such a tall residential tower, also had to be planned from the start of construction. Bovis figured out a way to keep the external hoist operating so that workers could get materials to upper floors even with lower floors occupied. “We are not turning over the unit [adjacent to the hoist] on each floor until the hoist comes down,” says Read. “The homeowners know what that is going to look like.”

Condo owners also have been forewarned that construction is set to begin late next month on the second tower. At 52 stories, it is not as tall as ORH. But work will still kick up the usual dust and make a lot of noise.

Post a comment to this article

Report Abusive Comment