Nancy Soulliard/ENR |

The structural-steel slip connection of a girder at the X-9 expansion joint that runs in the short direction of the David L. Lawrence Convention Center in Pittsburgh is a detail that at least some structural engineers don’t favor, a source told ENR. The second–floor slotted connection failed on Feb. 5 in the loading dock area over the main entry road and walkway, causing the girder to fail, along with a 60 x 20-ft section of precast concrete flooring that spans between girders. No one was killed.

The girders to either side of the failed girder did not pull away because they had a “seat” under the connection, says the source. The girder to the south had failed in 2005 and had been retrofitted using the seat, which is like a haunch, he says.

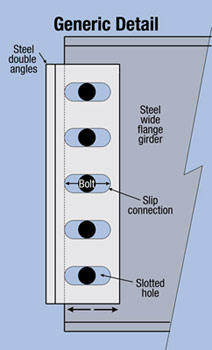

More seats will now be added as a remedy for the rest of the girders. The steel shelf angles or haunches will be placed directly under the slotted connections at the expansion joint. A Teflon bearing pad will allow the girder to slip—expanding or contracting in response to thermal stresses.

A report released Feb. 21 states that the girder, which spans between trusses and is connected to the expansion joint’s steel beam via welded angles, pulled away from the connection for it and was unable to slip, or contract, in response to falling temperatures.

|

“The threaded bolt gouged down, creating a pothole of sorts in the slot, and the girder could no longer contract to accommodate thermal changes,” says the source. Thread marks cut into the pothole are visible, he adds. Ultimately, the frozen connection put too much stress on the girder-to-expansion-joint beam weld and the weld failed, he says.

The silver lining to the collapse is that structural engineers will have ammunition to justify using other types of details on future jobs, says the source. Fabricators seem to like the connection, he adds.

At a Feb. 21 press briefing at the convention center, Allegheny County Chief Executive Dan Onorato said he is confident the building is safe.

“I have to rely on the experts, and if we put in that shelving, or the sleeve or whatever the technical term is, and reinforce all these locations, and they say it’s OK to open, then I’m comfortable,” Onorato said. “I’m relying on the independent consultants to give us that—that’s why they’re speaking today.”

Another beam in the convention center had caused a problem in 2005. The beam dropped 2.5 inches, said Mary Conturo, executive director of the Allegheny County Sports & Exhibition Authority. “At that time we called in anyone that was responsible for that—the architect, the structural engineer, the steel fabricator and the steel erector,” Conturo said. “They all came and reviewed the situation and their response was that there was a bolt that was too tight, and that other bolts were checked, and that was the extent of what was done at that time.”

At the briefing, a forensic engineer described his review of connections in the building that were similar to the one that had failed. “In response to this we evaluated every location along that expansion joint that had a similar connection, that had a connection that relied on the slots in these double angles, that was exposed to the weather in a similar way, that exhibited the same behavior during temperature changes as the one that failed,” said Gary Panariello of New York City-based Thornton-Tomasetti Group.

“We designed a retrofit to eliminate the need for the slotted angles by installing a seated connection and a Teflon bearing pad so that the beam actually sits on this seat and can slide back and forth in a frictionless manner,” said Panariello.

“This had been done on the four locations, three on the third floor and one on the second, that we could identify, that were similar enough to the one that failed to cause us concern,” he said. “There are no other connections in the building similar enough in weather, geometry or behavior that they need to be retrofitted at this moment for safety.”

The convention center is set to reopen March 9 after remedial work on the girders.

Related Links:

Related Links:

Post a comment to this article

Report Abusive Comment