Products 07/28/2010

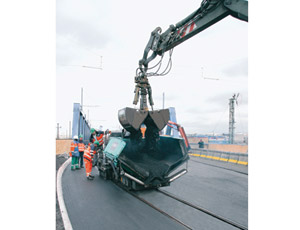

| Mini Paver: Adjustable Screed Width for Narrow Paving Jobs The Super 700 Mini Paver is capable of paving widths of up to 10 ft, 6 in., with a track width of only 3 ft, 7 in. The Mini Paver is powered by a 60-hp Deutz engine and is intended for small paving jobs, such as backfilling trenches, cycle paths or surfacing small traffic areas and minor roads. The Super 700 is equipped with a AB 200 V Extending Screed, which can be adjusted hydraulically. The AB 200 V Extending Screed features electric screed heating that ensures uniform distribution of heat across the screed plates. It also has an optional pave-width reduction package that can reduce the width to 1 ft, 7 in., without significant conversion. The screed floats on the mix with the pave reduction system attached, so compaction quality is not affected. The Super 700 Mini Paver is able to lay down 220 tons per hour. Joseph Vögele AG; +490-621-8105-392; www.voegele.info |

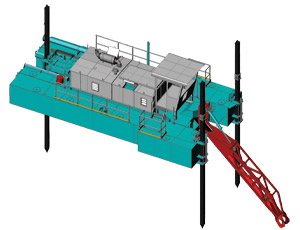

| Built to Order: Bureau of Reclamation Spends ARRA Funds on Custom Dredge for Specific Site Keeping the Imperial Diversion Dam on the Lower Colorado River properly dredged and free of excess sediment has been an ongoing struggle for the Yuma, Ariz., office of the U.S. Bureau of Reclamation. Contractors had been hired time and again, but a more permanent solution was needed. The American Recovery and Reinvestment Act of 2009 allocated money for long-overdue BuRec projects, giving BuRec the opportunity to put out a $3-million contract for its own dredge, which was awarded on June 29, 2010, to Ellicott Dredges, headquartered in Baltimore. “The dredge is being designed to meet their specifications,” says Paul Quinn, vice president of Ellicott Dredges. “We are looking at a four-month design process and a six-month build time.” The custom-model 860SL dredge will be based on Ellicott’s smaller 460SL dredge. The Imperial Diversion Dam’s site characteristics are driving the design of the custom-model 860SL dredge. “Most dredges are not designed to work in 120� heat, unless you’re working in the Persian Gulf,” says Quinn. “You can’t use radiators. You need oversized, high-efficiency heat exchangers.” Limited access is also an issue. The dam’s disposal site for removed sediment is roughly 16,000 ft from the dam wall, unusually far for a dredging operation. The 860SL will be powered by a Tier-3, 800-hp Caterpillar C27 diesel engine and will feature a 14-in. x 14-in. Ellicott Pump, with booster stations to help cover the distance to the disposal site. In addition to deep dredging along the dam, the dredge will have to work in small, confined areas, including in the Colorado River itself. There is a nearby marina, which may interfere with the underwater cables used to stabilize a conventional dredge. Therefore, the 860SL dredge also will be able to operate in a cable-less “swinging ladder” mode, which is “pretty odd for a large dredge,” says Quinn. “Until ARRA, only about 10% of our orders were federal. Now we’re selling a lot of standard dredges, but few as [customized] as this one.” Ellicott Dredges; 888-870-3005; www.dredge.com |

| Upgraded Joist: Handles Heavier Loads The iLevel TJI 560D Series wood I-joist now has a working depth of up to 24 in. The joist is suitable for use in one-hour fire separations and for supporting the heavier loads seen in multifamily and light commercial construction. The TJI 560D Series now is included in iLevel’s Javelin structural-frame design software and Forte single-member sizing software, allowing for easy substitution during planning. Weyerhaeuser Co.; 800-525-5440; www.weyerhaeuser.com |

| Framing Clamps: Also Works on Retrofit The Joist Grip Framing Clamp System from the Chicago Clamp Co. is installed underneath existing corrugated roof deck, and has a distributed load capacity of 4,000 lb., which allows it to support rooftop units, exhaust fans and skylights. The framing system is bolted into place, requiring no welding or drilling. The standard Joist Grip System includes four jaw clamps, four T-brackets and four pieces of 2-in. x 4-in. x 1/8-in. structural-grade tubing. The jaw clamp simply slides over the top joist chord and underneath the roof deck, simplifying retrofit projects. Chicago Clamp Co.; 708-343-8311; www.chicagoclampcompany.com |

Post a comment to this article

Report Abusive Comment