Building information modeling has come a long way recently, but it is still far from being business as usual. That, and lack of BIM software interoperability, were about the only two subjects of general agreement regarding BIM among the 60 attendees of a recent “eConstruction” roundtable, in Phoenix. As recently as two years ago, there were no model BIM contracts and most designers did not have staff trained on BIM, said John Cross, a vice president of the American Institute of Steel Construction, Chicago, which cohosted the March 31 session with the American College of Construction Lawyers.

“People are not waiting for the silver bullet to start using BIM,” said Derek Kunz, director of project development in the Denver office of Mortenson Construction. Kunz added that BIM-enabled jobs still have “heavy” learning curves.

David Hutchinson, president of Buehler & Buehler, Sacramento, added that for a small structural engineer, software is “manageable” not perfect.

Interoperability and reliability deficits are keeping many engineers, concerned about liability, from sharing BIMs with contractors, especially without disclaimers. Contractors and fabricators often create new BIMs from 2-D contract documents, which defeats one of the potential efficiencies of BIM: Generate content once and use it many times.

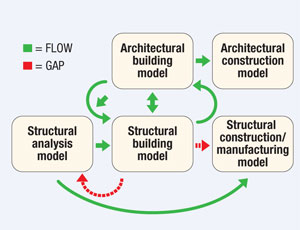

While engineers have “work-arounds” to pass data from structural analysis model to building model to manufacturing model, the work flow is not as automated as it could be or as software vendors say it is. “This is misleading to owners who issue design documentation requirements,” says D. Kirk Harman, president of the Harman Group, Philadelphia.

There are some efforts to ease BIM disconnects. The Applied Technology Council is developing software exchange standards for the structural domain. But the fruits of the labors of the ATC-75 project are far off.

Steel fabricators are still using an early steel data-exchange standard, called CIS/2, implemented by more than 20 vendors. But there are problems. Though implemented by AISC, CIS/2 is not fully supported by an organization. That means a lack of dissemination of information to end users and software developers, said Robert Lipman, a computer and civil engineer with the National Institute of Standards & Technology. There is also no oversight regarding CIS/2 implementations in BIM software and no conformance or interoperability testing program.

On the progress side, one attendee observed that more players in building construction “are willing to listen to a different type of project-delivery scenario,” which is needed for optimum use of BIM. One of these is integrated project delivery, which relies on contractual sharing of risk and reward among the owner, architect and contractor.

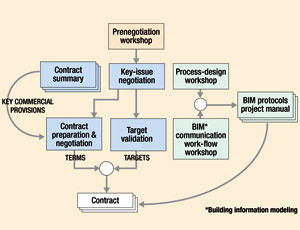

Lawyer Howard W. Ashcraft of Hanson Bridgett offered an IPD contract negotiation work flow, which he says can be used for a non-IPD BIM-enabled project as well. Though some contractors see IPD as the next best thing since sliced bread, many structural engineers see it as a potential nightmare. BIM presents information technology risks and requires a much higher degree of dimensional accuracy and modeling. With IPD, designers, which don’t often get paid extra for BIM, take on more risk and contractors get the reward, said one engineer.

On their long list of recommendations, attendees advised AISC to get more involved with software standards, to help develop new methods to deliver steel structures to reap BIM’s advantages and to collect data to show BIM’s benefits.

Post a comment to this article

Report Abusive Comment