Hemmed in on one side by the ocean shore and on the other by a major live rail line, the NZ $50-million, or U.S. $37.5-million, Ngauranga to Aotea Quay Upgrade is finally coming to grips with one of the nation’s most congested stretches of highway.

New Zealand’s State Highway One (SH1) is the nation’s most important road, linking the capital, Wellington, to Auckland and running the entire length of the North Island. Traffic engineers are unplugging a number of bottlenecks to reduce journey times and improve safety as the country’s population grows and traffic increases.

One urgent project is repairing a notorious section of Wellington’s heavily used urban motorway between Ngauranga and Aotea Quay that bedevils drivers commuting into the city from the north. The project brings together a host of engineering skills from contractor Fletcher Construction Co. and consultant Beca Infrastructure. First to use New Zealand Transport Agency’s (NZTA) Active Transport Management System (ATMS), the 3-kilometer upgrade will be a key link in the country’s first “smart motorway.”

Glen Prince, NZTA project manager for the upgrade for the NZ Transport Agency, explains why it is such a challenge for contractors, saying, “Generally, a lot of the site is on reclaimed land filled when the Wellington Motorway was constructed in the 1970s,” he says. Extensive ground investigations show, in general, well-compacted reclamation fill, dating from the 1950s, over marine gravels.

“The properties of the in-situ soils [along the route] have been assessed through ground investigations, which are then used to inform the design of the gantry structures and pavement design, along with modifications to an existing structure, which is being incorporated into the works,” he adds.

This structure—known as the Thorndon Bridge stub structure, an off-ramp parallel to the northern four spans of the Thorndon Overbridge—was built at the same time as the original bridge but is not currently operational. The existing foundation-and-pier structures are being re-used at this point. The site, in a region of regular seismic activity, has required additional testing and monitoring.

While the contractor makes space for the fourth lane, the unused bridge stub has been put back into service, saving money and preventing undue disruption. Left over from the Thorndon Overbridge’s early 1960s construction, the bridge stub requires widening to fit the fourth lane.

“Widening a large structure like the overbridge would need a significant amount of structural work,” says Prince. “Because the stub off-ramp bridge is very near, it’s more practical and cost-effective to move and re-use that structure, rather than construct a whole new bridge clip-on.”

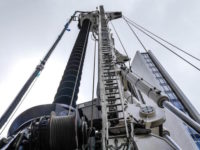

Later this month, FCC will use a computer-controlled, synchronized jacking system to lift and slide the existing bridge structure during the delicate bridge-realignment operation, which alone will cost $2 million, or U.S. $1.5 million. The contractor will lift the bridge structure 250 millimeters to facilitate the horizontal slide, demolition and reconstruction of the abutment. Crews then will lower the realigned bridge 900 mm onto new abutment bearings.

“From a technical point of view, the behavior of the ground beneath the Thorndon Overbridge and stub structure and the performance of the structures themselves are the most challenging” aspect of working within the confined site, says Prince.

Post a comment to this article

Report Abusive Comment