Auckland’s $1.8-billion City Rail Link (CRL) is under construction in New Zealand’s most populous metropolis, bringing an end to uncertainty that had frustrated plans to connect vital transport routes to the central business district.

Two initial contracts, together worth $205 million, involve the construction of twin tunnels beneath Albert Street, one of the city’s busiest arteries, and deep foundation underpinning works under the CBD's iconic Britomart transport hub.

Client Auckland Transport has chosen to adopt continuous real-time monitoring of buildings to keep a close check on any movements during the underground works and appease owners. The service is provided by international specialist Soldata.

CRL, which is expected to take five and a half years to complete, will feature twin 3.4-kilometer-long tunnels driven at a depth of up to 42 meters below the city streets, creating an underground rail line linking Britomart and the city center with the existing western line near Mt Eden. It is a busy commuter route.

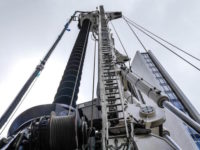

Included in the works are two new underground stations at Aotea Square (11 m deep) and Karangahape Road (33 m deep) along with a redeveloped Mt Eden Station. The project work horse is a 7.5-m-dia tunnel boring machine (TBM).

A Downer Soletanche Bachy joint venture is undertaking Contract One, the $116-million Britomart underpinning and associated works. Meanwhile Connectus, a joint venture made up of Hawkins and McConnell Dowell, is delivering Contract Two, involving the construction of 350 m of twin cut-and-cover tunnels along Albert Street. It also involves diverting an existing stormwater tunnel. The diversion is being constructed by pipejacking a 2-m-dia pipeline along the eastern side of the busy thoroughfare, between Swanson Street and Wellesley Street in the CBD.

A certain amount of ground movement is expected, according to Scott Elwarth, Auckland Transport’s CRL construction manager. “There is an obligation to monitor the environment closely through the works, as a condition of our consents,” he says. “We initially considered manual recording and monitoring, but then turned to Soldata, [which] suggested a continuous, automated, real-time monitoring regime. It means that if ground or building movements exceed predetermined limits, alarms are set off automatically to alert us. The system uses targets on buildings and ground retaining walls. We’re expecting movement, but only on a millimeter scale. If this is exceeded there is the option to stop work immediately.”

“Soldata has experience in building monitoring in urban tunnel environments, so we engaged [the company] to provide assurance for Albert Street’s property owners, insurers, Auckland Transport and the Connectus project team that things are going according to plan.”

Soldata’s remotely and robotically controlled laser system installed for CRL has five units and a network of 270 prisms (monitoring prisms, reference prisms and reflectorless measurement points) covering the length of Albert Street, including Swanson, Victoria and Wellesley Streets with sub-millimeter precision at up to 180 m from their location.

By monitoring any potential settlement of Albert Street using this reflectorless technology, which does not involve any installation of prisms or other equipment, the system is designed to be able to evolve and adjust to ongoing works. The network will expand to include seven units and over 500 measurement points once "cut and cover" trenching works begin on lower Albert Street.

The units measure the prisms’ exact location using an invisible laser beam emitted from the unit and reflected by the prism. From this beam the exact displacement between the unit and the prism is known. Successive measurements track the displacement of the prisms over time and consequently give advance warning of potential ground and building changes adjacent to construction, as well as performance of construction techniques as movement trends become visible. The reflectorless technology also allows for ground movement to be monitored in roadways and footpaths with active traffic. Monitoring data is available at all times. If the defined threshold of movement is exceeded, the system transmits an alarm email immediately.

The system includes other monitors, including inclinometers, which measure lateral change over the full depth of the installed borehole, and piezometers, which measure any variation in groundwater pressure within a defined aquifer.

Each piling shaft has these in order to monitor the movement of the retaining walls during excavation. Once excavation of the cut and cover begins, additional piezometers and inclinometers will be installed around the perimeter, and strain gauges are to be installed on struts within the excavation.

Eric Audige, Soldata’s managing director for Oceania, says the CRL project is significant for the company. “It certainly has its own challenges. The project has many constraints," he says. In particular, he notes "the monitoring of ground deformation along roadways and footpath where no physical instruments can be installed and of course down the track making sure the Britomart Station doesn’t move during jacking up and excavation.

“For that we are using our patented Cyclops and Centaur systems to remotely monitor in real-time all movements of building and road without putting people at risk on the street.

“The extent of monitoring was defined upstream by the client. However, our systems go further than the original requirements. The core of our solution is the Cyclops/Centaur system coupled with our sensor data management platform Geoscope. These solutions have been used on many international tunnel constructions but have been revised and upgraded over time. The CRL job in one hand is benefiting of these developments and on the other hand will trigger further developments because of its uniqueness.

“The monitoring of the Britomart station will be the most challenging part of the project for Soldata and where the very specific Cyclops evolution technology will be deployed. In short, the Evolution module puts multiple Cyclops in a single ecosystem instead of working in silos like in standard, common configuration. It will allow for monitoring simultaneously, in real-time and in a coherent way both the outside and inside components of the heritage building, which will provide key information for the main contractor. In that regard, the CRL job represents a world-class reference for us and New Zealand. It is similar to the solution we used in Barcelona, Spain, for monitoring the Sagrada Familia Cathedral.”

Post a comment to this article

Report Abusive Comment