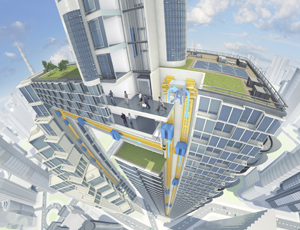

Looking to expand versatility in building designs, Essen, Germany-based ThyssenKrupp Elevator AG has announced Multi, a cable-less elevator system propelled by magnetic induction. Multi will allow multiple elevator cabs in a single shaft and be able to travel horizontally as well as vertically within a building.

According to ThyssenKrupp, the system will reduce the overall footprint of elevator shafts, increasing the usable space in high-rise buildings. "As the nature of building construction evolves, it is also necessary to adapt elevator systems to better suit the requirements of buildings and high volumes of passengers.," said ThyssenKrupp Elevator AG CEO Andreas Schierenbeck in a press statement. "From the one-dimensional vertical arrangement to a two-dimensional horizontal and vertical arrangement with more than one or two cabins operating in each shaft, Multi represents a proud moment in ThyssenKrupp’s history of presenting cutting-edge transport technologies."

The system would keep the elevator cabs moving at a near-constant five meters per second to ensure waiting times of no more than 15 seconds. The design is similar to the continuous-elevator "paternoster" design, which is still in use in some older buildings. The elevator cabs will use an induction technology similar to that used in magentic-levitation train systems, allowing each cab to circulate through the system independently.

Multi is partially based on the Twin elevator system that ThyssenKrupp introduced in 2003; it allows for two elevator cabs to operate in a single shaft. Twin is a cable-based system, but the electronic control system it uses to manage the elevators is being adapted for the Multi system.

While ThyssenKrupp says the Multi system is optimized for buildings over 300 meters, or 984 ft, tall, the system is versatile enough to work in buildings that don't reach the supertall category. The Multi system requires a footprint of only 6 sq m, or 64.5 sq ft—compared to the 9-sq-m, or 96.8-sq-ft, footprint of the Twin system—and uses carbon-fiber panels and other lightweight elements in the elevator cab to reduce the overall weight.

ThyssenKrupp is building a test tower in Rottweil, Germany, that will house a demonstration prototype of the system. It is set to be completed in late 2016.

Post a comment to this article

Report Abusive Comment