Those who work in construction are all too familiar with the safety concerns surrounding the industry. Despite advances in personal protective equipment (PPE), stricter regulations and enforcement, and the best efforts of dedicated HSE managers and their employers, being a construction site worker comes with an undeniable level of risk. On any given day, construction workers must navigate a range of potential safety threats, ranging from heavy equipment and electrical hazards to heights and long hours spent on the job.

Those who work in construction are all too familiar with the safety concerns surrounding the industry. Despite advances in personal protective equipment (PPE), stricter regulations and enforcement, and the best efforts of dedicated HSE managers and their employers, being a construction site worker comes with an undeniable level of risk. On any given day, construction workers must navigate a range of potential safety threats, ranging from heavy equipment and electrical hazards to heights and long hours spent on the job.

3 of the top 10 most

dangerous jobs are in construction.

Source: “The Most Dangerous Jobs in America,” CNBC

The frequency of fatal accidents, injuries, and other types of safety incidents in construction are higher than other industries, with 21.1% of workplace fatalities being construction-related.[1] These incidents don’t just shine a light on the need for improved safety precautions, they also come at a steep cost. It’s estimated that construction worker fatalities cost $5 billion per year in the U.S. alone. The construction industry’s costs for workers’ compensation is also 71% higher than all other goods-producing industries combined and more than 2X the cost for the average employer in all other industries.[2]

Construction worker fatalities cost the U.S.

nearly $5 billion each year.

Source: Midwest Economic Policy Institute

Suffice it to say that safety concerns are all too common on construction sites. Investigations into accidents and near-misses after the fact often reveal that the situation could have been avoided. While these investigations are useful for identifying lessons learned that hopefully are used to prevent future incidents, they are also reactive. To effectively reduce safety incidents on construction sites, more proactive safety measures are also required.

Better, More Effective Safety Training Must Be a Priority

Frequent and consistent safety training is universally recognized as being the easiest and best way to improve safety. Yet, not enough have committed to regular and rigorous safety training. While it’s easy to pay lip service to a safety-first culture, the realities are that too many construction contractors are still cutting corners. Faced with increased competition and razor-thin profit margins, contractors sometimes make poor decisions that unknowingly put the health and safety of their workers in danger.

Given the potential for loss of life alone, not to mention the exorbitant costs and negative impacts to the industry, improving safety on the construction site must be a priority for all involved. There’s no excuse for anything less than a complete commitment to safety. And there’s also no shortage of tools and resources to ensure thorough and effective safety training. Extended reality (XR) technologies like virtual, mixed, and augmented reality are helping construction companies create highly effective and cost-efficient safety training and learning programs.

How to Use Augmented Reality to Make Safety Training More Effective

By giving workers the ability to visualize 3D data of on-the-job hazards and learn how to manage real-world threats in a safe and virtual environment, safety training supported by augmented reality improves learning effectiveness, while reducing accidents and costs.

Here are 3 ways you can incorporate augmented reality (AR) into a regular safety training program to make your job sites safer and ensure your workforce is as prepared as possible.

1. Pre-construction Safety Planning

Taking the time to conduct a thorough assessment of risks before construction begins can significantly increase safety throughout the duration of the project. When you develop a site-specific safety plan during the preconstruction phase of each project, you make safety an integral part of the planning process, not an afterthought.

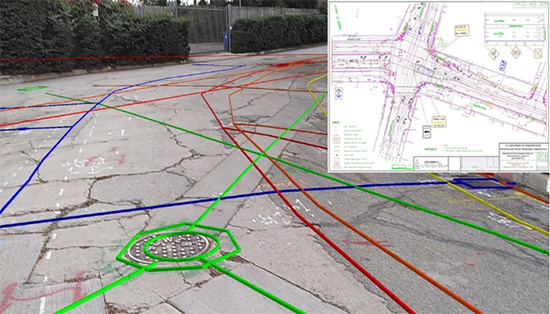

By creating models of heavy equipment work zones, for example, or the location of underground services, subsurface utilities, and other areas of concerns, you can use AR to show workers exactly where hazardous or ‘no-go’ areas are located and what they look like in their actual environment.

Using a smartphone or a tablet on the site, you can use AR to overlay these elements in their precise location and in realistic detail. By showing workers a clear visual picture of the hazards to avoid and in their natural context, you help them retain the information and improve their ability to safely navigate the job site and avoid potential threats. It’s estimated that 65% of people are visual learners (also known as spatial learners),[3] meaning that they learn and remember best through visual communication like charts, diagrams, and images.

Using AR to help workers identify and visualize underground services alone—including steam, gas, propane, and electrical systems, as well as communications and fiber optic cables—can significantly improve safety and reduce project costs. The Common Ground Alliance found that utility hits over the past 20 years have resulted in 421 deaths, 1,906 injuries, and $1.7 billion in property damage.[4]

2. AR Site Inspections

After an initial assessment of existing hazards, exposures, and control measures is done, enhancing your regular site inspections with AR can allow you to reassess safety conditions and identify new hazards. AR can be used to overlay the digital model on the as-built structure in real-time, making it possible to identify any discrepancies that could pose a threat to worker safety. Some augmented reality systems even allow recording of your as-built services with images and accurate positions to provide valuable context as other works progress on site, for identifying new hazards.

Incorporating the latest as built or design data into your routine site inspections allows more effective and meaningful safety meetings. During these meetings, AR images can be used to reinforce or test workers’ knowledge of the location of critical services, restricted areas, or other safety zones. This provides an opportunity to gather feedback from your workforce, who may be able to highlight site hazards or other issues that may not be clearly identified. You can also use these meetings to discuss near-misses. AR can help you safely review dangerous situations for workers, as well as illustrate the correct actions to be taken to prevent accidents.

It’s worth noting that mixed reality can also be used to increase safety. In the case of site inspections, mixed reality can be used by those inspecting the site to overlay BIM models against what’s being built. In this way, MR makes it possible to identify problem areas quickly and more easily. MR also makes it possible to incorporate safety measures directly into workflows. For example, a workflow sequencing the assembly of prefabricated components can begin with a safety message, as well as provide continued safety guidance relevant to each step of the process. Instead of safety being addressed as a separate initiative, MR makes it possible to integrate safety into the work being performed.

3. Enhance Your Daily Toolbox Talks

For safety training to be effective, it must be frequent, consistent, and engaging. To keep safety top of mind, daily site safety briefings (aka toolbox talks) throughout the duration of the project are commonly used to review the day’s work, highlight specific threats or concerns, and reinforce expectations around safety. During these informal safety talks, images and videos from AR systems such as Trimble’s SiteVision system, can be used to illustrate safety issues from the previous day, as well as help workers identify and visualize specific safety concerns for the coming day.

Toolbox talks are a critical component of site safety, however they are sometimes viewed as uninteresting or time-wasting by staff under pressure to deliver. The use of AR can help keep team members engaged, while the visual nature can quickly communicate complex safety issues and prevent meetings from running long. For example showing workers the extent of reach and the excluded operating area around cranes, visualized in 3D in the context of the site using AR models.

Honing your workers’ ability to visualize hazards is an important skill that can have a significant lasting impact on safety outcomes. Companies like Cummins, who makes the diesel engines and power generators often seen on construction sites, and Owens Corning, who manufactures insulation, roofing, and fiberglass composites, are training employees how to better see hazards and are finding that teaching workers this invaluable skill is helping them identify safety hazards they might not have noticed otherwise.

“Visual literacy helps employees to better see hazards

that they otherwise wouldn’t be noticing on a day-to-day basis; things they are so familiar with they might just walk by.”

—Kelli Smith, Occupational Health Director, Cummins

Improve Construction Site Safety with Augmented Reality

Given the very real potential for injuries and deaths, and the associated costs that ultimately hurt everyone in the industry, there’s no excuse for not prioritizing safety. As if that isn’t reason enough, there are also many benefits to a making a dedicated commitment to safety, including:

- Improvements in productivity and quality

- Better employee morale

- More effective employee recruiting and retention

- A more favorable image and reputation among customers, suppliers, and the community.[5]

The use of extended reality technologies like AR can help you breathe new energy and effectiveness into your safety training program and demonstrate a renewed commitment to the health and safety of your workforce.

To learn how one construction company is using AR to improve crew safety and reduce the risk of utility strikes, watch the interview now.

[1] Commonly Used Statistics. OSHA.gov.

[2] The Construction Chart Book: The U.S. Construction Industry and Its Workers. CPWR – The Center for Construction Research and Training. 2018

[3] St. Louis, Molly. “How to Spot Visual, Auditory, and Kinesthetic-Learning Executives.” Inc. August 1, 2017.

[4] “Underground Utility Strikes USA.” 1300Locate. May 22, 2019.

[5] Recommended Practices for Safety & Health Programs in Construction. OSHA. October 2016.

Post a comment to this article

Report Abusive Comment