The recent launch of the beta version of the Embodied Carbon in Construction Calculator represents a significant milestone in the management of EC in building materials. But the EC3 team, and the firms piloting the tool, have a long road ahead of them before the tool is comprehensive, perfected and integrated into daily practice.

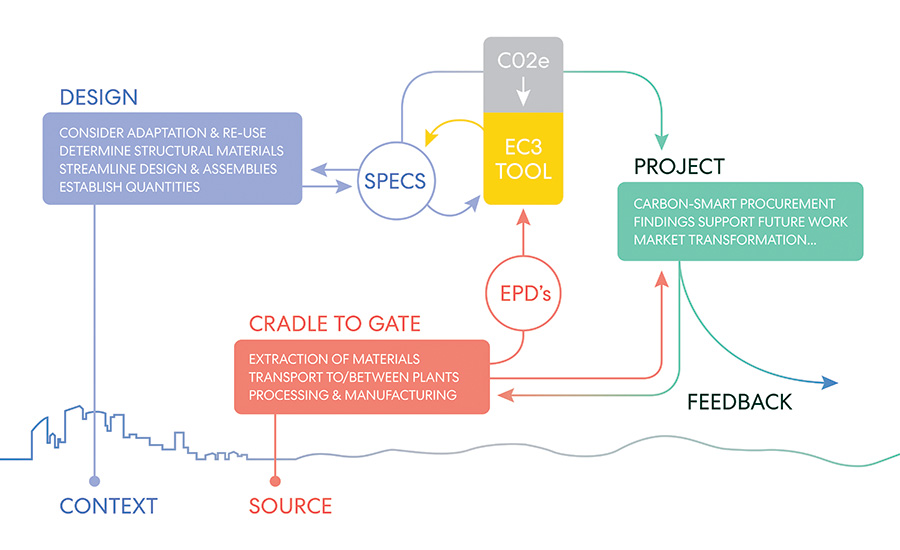

Released Nov. 19 at Greenbuild 2019 in Atlanta, EC3 is a free, open-access tool, based on the first database of digitized environmental product declarations. EPDs, which are at the heart of the tool, provide quantified environmental data for a product, including the global warming potential (GWP) from greenhouse gases emitted during material supply, manufacturing and delivery to the jobsite.

“It’s an incredible technology and is transforming our industry’s ability to understand, calculate and assess the EC content of buildings we’re designing,” says Kimberly Seigel, research knowledge manager for architect Perkins and Will (P&W), which is piloting the tool on two projects.

Skanska USA and C Change Labs conceived of EC3. Skanska and Microsoft jointly funded initial development. To expand the tool, the Carbon Leadership Forum (CLF) incubated the project with more financial support from Autodesk, Interface, the MKA Foundation and the Charles Pankow Foundation—lead sponsor and grant manager for the $713,000 EC3 project, which now has nearly 50 supporters (ENR 11/4-11/19 p. 24).

On one P&W pilot—the $90-million Newark Civic Center in California—P&W and contractor Webcor, which are exploring the tool in tandem, go over initial takeoffs to ensure what is specified feeds into the tool.

EC3 is for architects, engineers, owners, contractors, material suppliers and policy makers. Prior to EC3, which also includes visualization tools, users were hampered by PDF-based EPDs that are not easy to compare.

Searchable and Sortable

EC3 is the first free tool that allows for specific analysis of EC data in the supply chain, using the first searchable and sortable database of all U.S. and Canadian EPDs. The tool connects to BIM 360, Autodesk’s cloud-based construction management platform.

In a few clicks, users can choose desired performance criteria, such as the compressive strength of a concrete mix, as well as GWP, and can see selections mapped in a 3D view. Users can analyze the EC in a material in 10 to 15 seconds. It takes 15 to 30 minutes for a project.

There are limits to the initial release of the tool. EPD numbers keep growing, but they are uneven. Of the 19,000-plus digitized EPDs, concrete dominates with more than 18,000.

There are about 338 for flooring, 336 for thermal and moisture protection, 193 for aggregates, 167 for steel and 148 for ceiling panels. There are only 81 each for gypsum board and openings, 80 for finishes, 29 for wood, 26 for aluminum, 22 for bulk materials, 12 for cladding and nine for asphalt.

The EPDs come from about 50 companies, each with at least 10 EPDs, and 16 with more than 100 each. Geographically, EPDs are heavily biased toward the Pacific Coast, though the number in the Eastern U.S. is growing, says Phil Northcott, CEO of C Change Labs, EC3’s software developer. The expansion is driven by owners and architects asking for EPDs from suppliers, he adds.

There are other limits. It is difficult to compare similar materials because most EPDs are based on industry-wide averages rather than plant-specific or product-specific data.

Another limit is that not all EPDs report key details about product performance, requiring users to interpret the data, says Kate Simonen, CLF’s director.

The goal is to have all building products in a database that enables meaningful comparison. “We need a digital data EC ecosystem,” says Simonen.

One aim is to make sure that 95% of the potential EC in a building is covered by verified EPDs. Toward that end, Simonen and Stacy Smedley, Skanska’s director of sustainability and the catalyst for the tool, are pounding the pavement, engaging with manufacturers.

Looking toward the future, Northcott would like to see the tool expanded to track EC during a project, “so we can close the loop,” by comparing actual EC in the building to the plans.

The tool’s users are the best group to make EC reduction standard practice, says Northcott. They need to make verified EPDs a requirement, he maintains. “Once that happens, it is on us, and consultants working with us, to help manufacturers make the transition to routine generation of EPDs,” Northcott says.

For user P&W, the tool has great potential for it offers one-stop shopping for EC reduction. The industry collaboration that created the tool is “impressive,” says Seigel.

By Nadine M. Post with Joann Gonchar

Post a comment to this article

Report Abusive Comment