Photo:C.J. Schexnayder

|

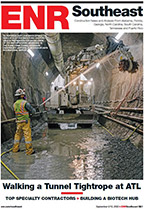

CAMPOS NOVOS, Brazil – The photo on the wall at the Campos Novos job site in Southern Brazil is impressive. It shows the the third tallest concrete-faced rockfill dam in the world holding a full reservoir and waiting for its powerplant to go online.

If all had gone as planned, that would have occurred in December of this year. But all didn’t go as planned.

Late in June, just days after the photo was taken, a failure in one of the two tunnels built to divert the Canoas River during the 626-ft-tall (202 meters) dam’s construction allowed the entire reservoir to completely drain an estimated 1.2 billion cubic meters of water.s

“Campos Novos was going to be our proudest achievement,” said José Ayres de Campos the engineering director for the Brazilian construction firm, Construções e Comércio Camargo Corrêa S.A., Sao Paulo. “And then this happened.”

Today, the dam itself stands in stark contrast to the photo on the office wall. The empty reservoir is lined by dead vegetation and work crews crawl over the site doing repairs. Late last month, engineers re-opened the working diversion tunnel and began plugging the one that failed.

|

But serious questions about the future of the $554.4-million project remain. De Campos and other Camargo Corrêa officials are optimistic. Although the project has been set back substantially, there is no damage to the structure itself and they are confident their plan to repair the diversion tunnels will get the project back on track.

“It has turned into one of the biggest challenges we have ever faced,” de Campos said.

The Brazilian energy agency ANEEL seems to agree with that assessment. A seven-member panel of experts that filed a report to the agency in early September attesting that the dam itself is sound and the ability of the project to generate power has not been compromised.

“The ability of Campos Novos to produce electricity is not in any doubt,” said Fabio de Gennaro Castro, a member of the Brazilian chapter of the International Commission on Large Dams who reviewed the project for that group’s technical committee on safety.

Photo:C.J. Schexnayder Cracks in dam face (top) are not a problem, engineers say, but diversion tunnel gate failure (bottom) is another matter.

|

One thing that remains unclear is the final price tag of the incident. Although repair costs and penalties could push the final cost of the project up by as much as 20, officials with Camargo Corrêa say they are confident the final amount will be significantly less than that.

The final cost of the repairs, which de Campos says will not exceed 10 percent of the project cost, has not been precisely identified since the company is still assessing the amount and conducting negotiations with the insurance company.

Similarly, penalties for not meeting the project’s 54-month deadline are capped at 10 percent. The project had already been significantly delayed prior to the problem with the diversion tunnel. Contractual schedule set forth a 54-month construction period concluding January 30, 2006, with the last of the turbines going on line by August.

Camargo Corrêa officials are in negotiations on the issue with the consortium that holds the 35-year build and operate concession for the dam, Enercan. The group consists of Brazilian power company CPFL Energia with 48.7 percent; Brazilian aluminum makers CBA with 22.7 percent; metallurgy company CNT with 20 percent and two state-run electric companies.

Drainage Tunnel Failure

To construct the dam, the contractor dug two tunnels of 2,823.75 feet (860.9 meters) and 3,003.82 feet (915.8 meters) in length to divert the water from the river around the dam during construction. The tunnels were roughly square in shape 52.48 feet (16 meters) high and about 13.12 feet (4 meters wide).

The intake structure for each tunnel features three passages 14 meters high and 4 meters wide that allow metal bulkhead gates to be lowered and stop the water flow. On October 10, 2005 all six gates were closed and the reservoir was allowed to fill and work was started on the concrete plugs for the tunnels. Within a month the reservoir had reached 93 percent of the maximum head holding almost 1.6 billion cubic meters of water.

Ten days after the gates were shut, the longer tunnel, Tunnel 2, developed a leak that engineers later attributed to a faulty seal likely caused by the collapse of a secondary concrete beam in the intake structure. Metal gratings were fitted into the fissure and sealing materials were injected, stopping the flow. This seemed to solve the problem and work to plug the tunnel resumed.

Almost six months later, on April 1 water levels in Tunnel 2 again started to rise–reaching about 20 meters per second. Within a week this flow had reached 150 meters per second. Engineers began decreasing the water level in the reservoir to help limit the flow and began attempting to seal the fissures in the intake structure as they had before.

Despite the efforts, the size of the fissures began to increase and, by June 5, the flow had reached 165 cubic meters per second. On June 19, the force of the water cut the pillar between two of the openings on Tunnel 2, which lifted the bulkhead doors off their bases and tore them away. At that point, flow volumes into the tunnel surged to more than 4,000 meters per second, draining the reservoir in the less than 48 hours.

The water flowed 15 miles (24 kilometers) downstream where it was collected in the reservoir for the 1,450MW Machadinho hydropower project located in the Pelotas River. Due to a regional drought, the water levels there were exceptionally low and the additional inflow filled the reservoir.

Photo:C.J. Schexnayder Crew unplugs one tunnel before plugging the other.

|

Repair Plan

During the last week of September, engineers opened the gates to Tunnel 1 after removing the concrete plugs that had been put in place. With the waters of the Canoas River flowing through Tunnel 1 it once again work can begin to fix Tunnel 2.

“We know that Tunnel 1 works,” said Project Director Jose Carlos da Silva. “So we are going to use it in order to handle the situation with Tunnel 2.”

Camargo will construct a cofferdam on the egress of Tunnel 2 and place new concrete plugs. The first plug will be 13 meters thick and should take approximately two weeks to install. It will work to stop all water from flowing into the tunnel allowing a permanent plug 33 meter thick to be built.

When the permanent plug is complete, the gates on Tunnel 1 will be lowered as before allowing the reservoir to refill. If there are no further difficulties, a temporary then permanent plug will be inserted into that tunnel as well.

The repairs are on a five-month schedule but there is one more problem looming. When the gates were initially closed last year, it was during the rainy season. It is likely the work on the tunnels will be done early next year, during the dry season which may take as much as four months to fill the reservoir.

Surface Cracks

The most visually arresting aspect of the incident has been the cracks in the concrete surface of the dam that the drained reservoir revealed. Camargo Corrêa insists the damage is superficial and does not indicate any structural damage to the interior of the dam itself.

The rock core, consisting of more than 12 million cubic meters of basalt quarried on site, has been subjected to the total weight of the reservoir at maximum head and shown no sign of failure, de Campos said.

“These cracks did not cause the emptying of the reservoir,” de Campos said. “And they do not indicate any flaw in the structure of the dam itself.”

According to Camargo Correa, the maximum amount of water percolating thorough the structure while the reservoir was full never exceeded 1.4 cubic meters per second – an amount considered acceptable for the this type of dam.

Camargo engineers say they believe insufficient spacing between the slabs was what caused the cracks. Each of the concrete face slabs is 16 meters wide and varies between 30 centimeters and one meter in thickness. But the deflection of the concrete face due to the steep sides of the dam–almost 45 degrees–was as much as 86 centimeters in some spots.

Post a comment to this article

Report Abusive Comment