William G. Krizan / ENR Modular loader-backhoe armor was developed by Case for military

|

It’s showtime for heavy equipment as the worksite of the future evolves to meet the fast-paced needs of the 21st century. Electric drive, pioneered in the last century by earthmoving legend R.G. LeTourneau, is one method suppliers are tapping to push machines to new levels of productivity.

In today’s environment, project plans move so quickly that once contractors get mobilized, “we’re already late,” says Steve L. Massie, chief executive of Williamsburg, Va.-based Jack L. Massie Contractor Inc. and past president of the Associated General Contractors of America. Equipment that works cleaner, more safely and productively “is absolutely critical,” Massie said on March 10 at the Bellagio hotel-casino in Las Vegas, where ENR and AGC hosted a half-day summit titled “Equipment for the 21st Century.”

CONEXPO/Oscar Einzig Photographers CONEXPO drew a swarm of 144,600 people, beating 1999’s record by more than 16%.

|

Across town the following morning, a swarm of more than 127,000 pre-registered contractors and engineers piled into the Las Vegas Convention Center to attend CONEXPO-CON/AGG 2008 and get a look at the latest iron. The construction industry’s largest event of the year drew in a record 144,600 people before the 2.28-million-sq-ft show closed its doors on March 15.

Nearly 2,200 suppliers brought equipment, software, tools and widgets as attendees kicked tires, drank beer and talked shop. Despite a softening economy and credit crunch, CONEXPO boomed. A large international audience accounted for 19% of the total turnout, with 26,000 people from 120 countries. The triennial show brought 60 official international buyer delegations, up from 44 in 2005.

The staging required roughly 18 billion lb of freight spread across 48 acres. Vendors ranged from small hydraulic suppliers to multinational firms like Liebherr Group, which packed $25 million of equipment into its 50,000-sq-ft booth, including the world’s largest hydrostatic wheel loader and a hulking, 660-ton crawler crane worth $5 million to $6 million. Case Construction Equipment showed an armored loader-backhoe developed for the U.S. military.

Earthmoving equipment on display offered big surprises. It was clear to many walking the aisles that electric power, pushed in the last century but never making its way much beyond large mining haulers, is again a focus. “LeTourneau is coming back,” noted Mike Vorster, professor of construction engineering and management at Blacksburg, Va.-based Virginia Tech.

| + click to enlarge |

Caterpillar |

Tudor Van Hampton /ENR |

Cat’s D7E (Top) sported AC electric drive with 60% fewer moving parts; Volvo (Middle) showed the L220F hybrid with lithiumion batteries; Deere went a different route with its 764 High Speed Dozer.

|

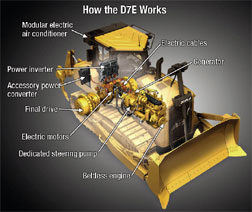

First out of the chute was Peoria, Ill.-based Caterpillar Inc.’s plain-looking yet attention-grabbing D7E crawler tractor, sporting a 235-hp diesel engine wired to a generator and two liquid-cooled, brushless AC motors that drive a low-track undercarriage with differential steering. With 100 patents granted or pending, the machine had no mechanical transmission, yielding 60% fewer moving parts than the current D7R and promising a 25% gain in material moved per gallon of fuel.

The electric dozer could be a hint of what is coming on other pieces of heavy machinery. Cat engineers said the decision to move to a low-track drive, rather than the company’s signature elevated sprocket, was not taken lightly but better positions the machine for a wider range of uses. Cat noted it will keep high drive on larger dozers but suggested electric drive may become standard on other units as the technology matures.

“We’re just getting started,” said Mike Betz, D7E chief engineer. The beltless engine is dialed down to a narrower speed range, which helps control the burn and after-treatment for future emission regulations, commonly called Tier 4, coming in the next decade. Cat rolled out other efficient earthmovers, such as a “smart” soil compactor that tells operators when they have reached a preset specification. The show marked Cat’s first entry into the towed-scraper market in over 30 years.

Sweden-based Volvo Construction Equipment showed a prototype, also available next year, of its L220F Hybrid, powered by a diesel engine mated to a starter/alternator, mechanical transmission and lithium-ion batteries packed with more than 600...

Post a comment to this article

Report Abusive Comment