Researchers at the Worcester Polytechnic Institute are seeking additional funding and a suitable parking lot for a large-scale test of harvesting heat energy from solar-heated asphalt pavement. The search follows several years of successful computer modeling and laboratory mock-ups.

| + click to enlarge |

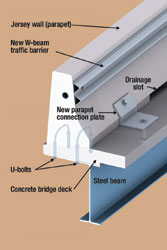

Bao-Liang Chen/WPI

|

Bao-Liang Chen/WPI Computer model of asphalt slab shows heat collection and dissipation.

|

“We have been working on heat flow through pavements for several years,” says Rajib B. Mallick, associate professor of civil and environmental engineering at WPI’s Worcester, Mass., campus. “Michael S. Hulen, president of Novotech Inc. (Acton, Mass.) came up with the idea and asked us to look at it.”

According to Mallick, there have been some studies in Europe and Japan. “Now, after our work, we’ve identified the important factors and we know what doesn’t work,” he says. Japanese re-searchers have pumped river water through pavement as a way to reduce temperatures and heat deformation, and a Netherlands firm, Ooms Avenhorn Groep bv, has used the process to heat buildings and potentially to heat and cool roads, notes Mallick. A spokesperson for the National Asphalt Pavement Association, Lanham, Md., says it has not heard of any U.S. studies other than WPI.

Hulen founded Novotech, a night-vision optical firm, about eight years ago but he says he has been thinking about the heat-energy potential of asphalt for 10 years. “My firm works in long-wave infrared light, also know as heat, so extracting heat from asphalt seemed logical,” he says. “We did some preliminary work and received a U.S. patent for powering hybrid vehicles and heating and energizing buildings two years ago, but we needed lab collaboration before we could receive venture-capital funding. I went to WPI because it has a large asphalt-testing facility.

|

| MALLICK |

” The idea is simple—install piping below the asphalt surface and charge it with a low-boiling-point fluid that is cooler than the pavement. That reduces pavement temperature while heating the fluid, which then can be used for heating through a heat exchanger or for power using a thermal-electric generator. Mallick estimates the system will cost about $20-to-$50 per sq meter installed and says a 2,025-sq-m slab could generate up to 800 kWh per day in a New England summer. Sunnier areas can produce more.

The tests show the area of greatest heat absorption is just a few centimeters below the surface. Tweaking the asphalt mixture to include aggregate with higher conductivity, such as quartzite, also enhances performance. In the slab test, 3/4 in. dia. copper tubing was used.

“Firms are now approaching us with new interfaces that could increase heat flow,” says Mallick. “Solar and other technologies are constantly improving, which makes this technically and financially feasible.”

Mallick says the concept has great potential particularly given the amount of asphalt used in parking lots and roads. The researchers say parking lots are ideal, but roads are still a problem because of traffic loads and plowing. Mallick notes that asphalt continues to give off heat after sunset and the system could be installed whenever repaving is done. Another benefit is that the system’s heat absorption could help reduce air temperatures in urban areas.

Mallick is seeking at least $500,000 in funding and a big parking lot next to a large building to refine the system. Initial funding of about $50,000 came from the Massachusetts Technology Collaborative, Westborough, and WPI.

Post a comment to this article

Report Abusive Comment