People have always moved to where the water is, settling near rivers, oases and springs. But a dry, fast-growing Southern California water supplier is bringing the water to where the people are. San Marcos-based Vallecitos Water District, which serves part of San Diego County, is constructing what many call the largest prestressed concrete water-storage tank in the U.S. The 40-million-gallon reservoir will boost the district’s storage capacity by 55%. When completed in 2008, it will be buried in the hills and become nearly invisible.

The reservoir, called Twin Oaks II, is not VWD’s first monster tank. The district completed construction of Twin Oaks I, a 33.3-million-gallon tank, in 2001 at a cost of $16 million. Implementation of the U.S. Environmental Protection Agency’s surface water treatment rule in the mid-1980s forced VWD to take its one open reservoir, 75-million-gallon South Lake, out of service, leaving only 30 million gallons of storage. Since then, the district has worked to enhance its capacity as resources permit. Twin Oaks I was planned as the first of two and possibly three identical reservoirs on the site.

|

Planning for the new tank began in earnest in 2004, when Vallecitos retained Infrastructure Engineering Corp., Poway, Calif., with a $1.2-million contract for planning, design and construction management. The master plan requires storage equivalent to five days of average daily demand, currently between 18 million and 19 million gallons, says Dennis Lamb, VWD’s director of engineering and operations. The current storage capacity of 78 million gallons falls well short of the criteria, and adding another 33.3-million-gallon tank would have met the requirement. But other considerations prevailed. “I asked IEC to do a study to maximize the storage of the site as well as look at an adjacent parcel of land we own for a potential future reservoir,” says Lamb.

Thomas F. Armistead/ENR |

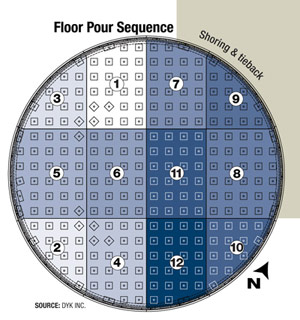

Infrastructure Engineering Corp. Vallecitos' Lamb (left) and Infrastructure Engineering�s Lewis jointly planned three-phase project. But unstable rock required shoring and tieback in northeast quadrant of the site, delaying release to tank contractor and limiting it to west half until October.

|

Strategic Thinking

The Twin Oaks site sits at elevation 1,028 in a hilly district with 27 pressure zones ranging from 1,608 down to 300. “We can move water anywhere in the district from here,” says Lamb. Siting and building a lot of small tanks at different elevations in the environmentally aware county would have been challenging. Lamb decided he could economically meet all foreseeable future storage needs by adding a single 40-million-gallon tank.

The tank’s size was limited by the location of the first tank on the west and by the property line on the north, says Preston H. Lewis, IEC president. It will have the same center as the original design. At 40 ft tall, its walls are the same height. But its diameter will be 434 ft, up from the original design’s 396 ft. Lamb, a baseball fan, illustrates its scale by referring to a 430-ft drive last year by Barry Bonds. “That would still be inside the tank,” he says.

IEC planned the project to proceed in three phases—mass grading, tank construction and final grading. The district secured funds with a $66.7-million bond issue to pay debt remaining from Twin Oaks I and to pay for the new tank and a reclamation facility now being built.

|

Bids were opened in August 2005 for mass grading. Wes-Tech Contracting, Escondido, Calif., was low in a field of seven with a bid of $2.198 million. The contractor began grading, transporting and stockpiling 217,000 cu yd of soil in November 2005, aiming for completion in February 2006.

DYK Inc. |

DYK Inc. First tank (on left, top) and shored corner limited access, and column pours couldn�t get ahead of roof pours.

|

Delay

Work proceeded smoothly until excavation uncovered unstable rock formations in the northeast quadrant, with heavily weathered, decomposed granite and intrusive volcanic layers with slip planes to the south-southwest. “There was a very high risk of tens of hundreds of tons of rock coming down” into the tank site, says Tom Hanley, Wes-Tech’s project manager and estimator. The quadrant’s high ground towers 60 ft over the site. “We had completed a large amount of site excavation and handed it over” before discovering this problem, says Hanley.

Under a subcontract, Condon-Johnson & Associates Inc., Oakland, Calif., shored the corner. CJA drilled vertical steel piles 30 ft to 60 ft long to shore up the north and east walls of the corner. The contractor then braced the 45° slope between them with cast-in-place circular concrete beams and tiebacks 80 ft into the native rock as excavation advanced. The beams, 4 ft high by 8 ft wide, were cast at 10-ft intervals starting 60 ft above the elevation of the final grade, with the tiebacks at 15 ft on centers entering the ground at a 20° angle.

Wes-Tech had found no rock elsewhere on the site. “We had very little indication that there would be this,” says Hanley. Wes-Tech accelerated the schedule, working six 10-hour days, because the follow-on tank-construction contractor had been scheduled to start in January. Still, executing the tieback plan required a $1-million change order and delayed completion of phase 1 to mid-October 2006.

DYK Inc. |

Tank Rolls

DYK Inc., El Cajon, Calif., began reservoir construction in June under a negotiated contract valued at $15.9 million. “It’s a little bit of a departure for the district,” says IEC’s Lewis. “There’s a big demand for construction,” largely because of California Dept. of Transportation projects, and heavy-civil contracting capacity is stretched. Demand for reconstruction of the Katrina-damaged Gulf Coast caused shortages of materials such as PVC, and concrete prices have risen 50% following local consolidation of small concrete suppliers, he says.

Photo: |

The situation called for a different approach from the one used for the first tank, when Vallecitos got six good bids for construction. DYK did the prestress wrap on that project as a subcontractor, and since then has come to dominate the tank market in the area. For Twin Oaks II, DYK put together an 80-page construction estimate, allowing IEC and the district to see all of the labor and numbers, says Lewis. IEC and DYK worked together six months on the design and finalized plans before establishing the cost. “It’s a modified design-build approach,” allowing the owner to retain some control of the design, he says.

When DYK received notice to proceed in June, Wes-Tech was still shoring. “It slowed us down a little bit,” says Shelly Anderson, DYK project manager, but the placement of 24,000 cu yd of concrete, delivered from a batch plant in San Marcos, quickly began on the west half of the site released to her.

Controlling logistics has been the biggest challenge, Anderson says. The 6-in.-thick floor is being poured in 12 sections averaging 144 x 96 ft, followed by wall monoliths, columns and roof sections. “If you get ahead on the columns, you can’t get the pump back in there to place concrete for the roof sections,” she says. Access is open at only one point, on the south of the site, because of the hilly topography and the adjacent tank. But the weather has been good. “This is San Diego County,” she observes.

DYK Inc. |

DYK Inc. Seismic cables half-buried in footing are inserted between rebar mats before being fanned out. The tank is designed to withstand peak ground acceleration of 0.4g.

|

Making the Monolith

The walls, tapering from 39 in. at the base to 12 in. at the top, are being poured as 29 monoliths, with Efco forms bolted together from 6 x 6-ft panels. Vertical prestressing is achieved by 638, 13⁄8-in. high-strength threadbars inside a 11⁄2-in. PVC pipe. For seismic restraint at the base, two rows of 0.6-in., 7-wire galvanized seismic cables, 17 ft, 8 in. long and in bundles of 10 strands are fanned out in the wall between rebar mats. At the top of each threadbar, a round, 5-in.-dia, 13-in.-long steel can nested with a square tube in the roof provides seismic restraint. Wall sections overlap 2 ft to form a construction joint. Prestressing compresses the joints with hydroseals making a watertight monolith of the entire tank.

The circumferential prestressing operation will begin after the floor, walls, columns and roof are in place. Following abrasive blasting of the core wall, workers will apply 3⁄8 in. of shotcrete and a layer of 3⁄8-in. stressing strand, alternating the shotcrete and strand layers five times before applying a final 11⁄2-in. layer of shotcrete coated in bitumastic for corrosion protection. The statistics reveal the staggering size of this tank. The 1,377.5-ft circumference will receive 962 prestressing wraps, totaling 251 miles of strand. A normal-size tank might use two or three reels of strand, says Anderson. This one uses 61 reels of 22,000 ft each.

DYK Inc. |

The 256 columns measure 2 ft, 6 in. in diameter and 37 ft, 5 in. tall. The 18-in.-thick roof is poured in 16 sections averaging 102 ft square. At ENR press time, one wall section remained to be poured and 11 of the roof sections were poured. Final completion of the tank construction is scheduled for December 2007.

With construction progressing, IEC is planning to advertise for bids in March for the $2-million final grading contract. Lamb is pleased with the project, noting that the cost to build Twin Oaks II is 39¢ per gallon, vs 33¢ for Tank 1. Community relations at the rural site, contentious before the first tank was built, have benefited from the district’s track record of quiet operation. When the final grading and landscaping contractor finishes with the site next year, 30 in. of soil will blanket the massive reservoir, and Vallecitos Water District will be prepared to support the region’s continued growth.

Post a comment to this article

Report Abusive Comment