|

...support LPD for hospitals. “Dave is the guy who suffered the slings and arrows of disbelievers in the system,” says Long. Lichtig adds, “We basically staked our professional reputations on this.”

A strategic move in 2003 was to invite Paul Reiser, Mr. Lean of the Boldt Co., Appleton, Wis., to speak to the Sutter facilities group. At some point, someone from Sutter asked Reiser if Boldt, which had been practicing lean since 1999, would consider working in California. The answer was yes. Boldt soon opened an office in Fairfield to work on the 69,000-sq-ft Sutter Regional Medical Foundation office building, nearing completion. Fairfield was Sutter’s first full lean-plus project. Reiser is currently project executive on Cathedral Hill.

Like an evangelist, Pixley knew he had to develop a following not just at Sutter but in the overheated marketplace to attract construction firms to work for Sutter, not its competition. In March 2004, Sutter held a meeting in Concord, Calif. “Our message was loud and clear,” says Pixley. “‘We intend to deliver projects differently. These are the basic aspects of the lean delivery model. We want you to come along with us.’”

DPR Construction Inc.; Nadine M. Post / ENR Using lean, Camino team saved $9 million, says the constructor.

|

Howell, who was then advising Sutter, says the message was like the shot heard around the world. “Fifty to 75% of the people were genuinely intrigued,” and hung around to learn more, he says.

Sutter began by applying LPD to manage its less-complicated medical office buildings, rather than hospitals. Its strategy is to build teams with the right chemistry. Experienced firms then are matched with newcomers on larger and larger jobs. The goal is to develop a level of proficiency in the entire Sutter community, says Pixley.

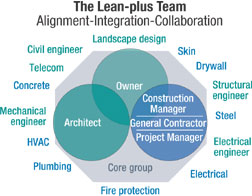

To learn the system, most Sutter firms attend LCI seminars. They also learn Sutter’s so-called five big ideas. The message borders on the evangelical. It says: “Collaborate, really collaborate; increase relatedness; optimize the whole; projects as networks of commitment; and tightly couple learning with action.”

The five big ideas, when applied together by major players, should result in what Sutter calls “emerging outcomes.” These are: innovation, competitiveness, trust, reliability and continuous improvement.

Sutter Health; Nadine M. Post / ENR Fairfield team is the first to use Sutter�s contract from the start of the job.

|

With integrated LPD, the team focuses on optimization and innovation rather than avoiding litigation. The CM/GC helps the designers with constructibility during a “validation” phase roughly equivalent to schematic design. Not only that, subcontractors help. “It’s exciting to be brought in early in design and viewed as a member of the core team,” says Chris Sorauf, senior project manager for Rosendin Electric, Fairfield’s San Jose, Calif.-based design-build contractor.

During design, questions are asked and answered, and adjustments made, across disciplines. The result is fewer RFIs. On Sutter’s 650,000-sq-ft Camino Medical Group’s Mountain View medical office building and parking garage, completed in April, there were six RFIs during the build-out of mechanical-electrical systems. “On a $100-million job, several hundred is typical,” says George Hurley, project executive for the San Jose, Calif., office of DPR Construction Inc.

For pricing, the team goes through a process LCI calls Target Value Design to collectively determine an estimated price. For scheduling, the team uses LCI’s Last Planner, which results in contractors making commitments based on what is really possible.

In Sutter’s world, there is collective risk and reward. The owner funds a contingency. If it is preserved and the cost of work is driven down, savings are shared with the team. If there is a cost overrun, team members fund it out of their collective profits up to limits established in the agreement.

For some of Sutter’s subcontractors, lean-plus is the deal-maker. “I wouldn’t necessarily be involved [on such a risky job] were it not for this process,” says Robert Weisman, senior estimator for Rosendin Electric, on Cathedral Hill.

But not everyone embraces the Sutter way. Long says large CM/GCs offer the most resistance. Though electricians and mechanical contractors glean onto LPD, drywall contractors don’t. “Trust doesn’t happen overnight,” says Dave Kievet, a Boldt executive vice president. “Helping each other is accepted to varying degrees by different vendors.”

Sutter now has five lean-plus projects in process, with a design and construction value of $1.5 billion. “We’re all engaged in this because we need to create a new model for the industry,” says Scott Muxen, systems integration manager with Herrero Boldt.

Kelly W. Smith, a vice president in the Oakland, Calif., office of Skanska USA Building Inc., also is working on San Carlos. “Lean is a great foundation for success,” he says.

Post a comment to this article

Report Abusive Comment