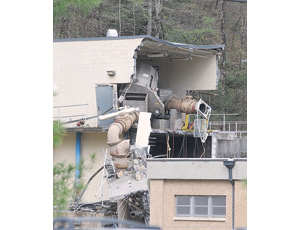

A Knoxville, Tenn., engineering firm is investigating the Gatlinburg Wastewater Treatment Plant where two workers died on April 5 after an equalization basin wall collapsed and more than 2 million gallons of raw sewage spilled into the Little Pigeon River.

Gatlinburg city officials on April 8 hired Construction Engineering Consultants, Knoxville, to investigate. Veolia Water North America, Chicago, has managed the plant since 1994.

“This was a catastrophic failure. Those guys were working in the valve input area in the middle of the tank [and] took the brunt of the whole wall collapse,” said Hal Deatherage, Construction Engineering principal, on April 11.

Deatherage said his firm will immediately check for conformance with the original plans, then start analytical work to verify the original design.

The 850,000-gallon tank consists of 12-in.-thick reinforced concrete walls 40 ft high. It was built by Crowder Construction Co., Bristol, Tenn., and engineered by Flynt Engineering, Knoxville. One end wall bowed after the first concrete placement in 1997. It was reinforced with a concrete buttress and is still standing. It has nothing to do with the collapse, Deatherage said.

As the tank has not yet been emptied, a structural inspection awaits to examine for cracking, signs of overload, separation of supports or signs of long-term exposure to corrosive materials, he said.

Veolia maintains, however, that its employees do daily walk-through inspections of the plant.

A possible factor for consideration, Deatherage said, is heavy rainfall the day before the collapse. “That increases the amount of water in the tank and could create an overload, ” he said.

The National Weather Service reported that 2.62 inches of rain fell on Gatlinburg in the 24 hours ending at 7 a.m. on April 5.

Meanwhile, the Tennessee Occupational Safety and Health Administration as well as the U.S. Environmental Protection Agency also are investigating the accident at the plant.

Plant operators restarted water treatment late on April 6 at a secondary level, which includes biological treatment. The plant is designed and permitted for an average daily flow of 3 million gallons, said Matt Demo, a Veolia spokesman. The actual daily flow averages 2.3 mgd.

The plant's process involves preliminary physical treatment, primary clarification, and single-stage nitrification, tertiary filtration and disinfection, including chlorination and dechlorination, he said.

Solids are handled with rotary thickeners, anaerobic digestion and centrifuge dewatering. The annually produced 243 dry tons of solids go to the county's composting plant.

The Tennessee Dept. of Environment and Conservation (TDEC) continues to monitor the river's water quality.

Drinking water remains safe in Gatlinburg and downstream in Pigeon Forge and Sevierville.

TDEC immediately began monitoring water downstream because the river runs alongside U.S. 441, the heavily traveled road that runs from Pigeon Forge to Gatlinburg and then to the Great Smoky Mountains National Park.

“We anticipate sampling will be required for some time,” said Tisha Calabrese-Benton, TDEC communications director.

Post a comment to this article

Report Abusive Comment