... the main footings. Eight drilled shafts support a footing, which is as long as 43 ft, as wide as 112 ft and up to 16 ft high.

High Performance

The high-performance concrete includes silica fume and fly ash to reduce permeability and thermal cracks. Kevin MacDonald, vice president of engineering services for Cemstone Products Co., Mendota Heights, Minn., the concrete supplier, says self-consolidating concrete used for the foundation shafts reached 10,000 psi in 28 days, double the strength requirement.

Tim Davis

|

Tim Davis

|

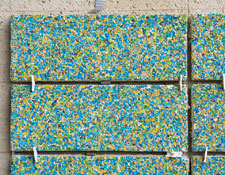

School children made tiles for an abutment. | |

The bridge decks are prestressed and bidirectionally post-tensioned. All steel for the superstructure is epoxy-coated or galvanized, say Figg engineers. Even the bridge railings will be galvanized and protected by a zinc-heavy paint.

Staying Warm

Tim Davis As many as six precast segments were placed in a day, with all 120 in place by August for the 504-ft-long main span.

|

Temporary shelters of plastic and canvas and hot air pumps and furnaces maintained the 40° temperature needed to cure concrete in sub-zero temperatures last winter, says Edwards. Eight beds simultaneously precast the 120 main span segments at a nearby yard. Finished segments were transported to a staging area on the river’s edge, then put on barges and floated into position for placement with a 750-ton ringer crane dubbed Big Ben. It arrived on site via two barges steadied with 60-ton concrete blocks, and was folded down to pass beneath bridges, says Edwards. With it, crews placed as many as six segments a day.

The project has provided educational opportunities for grade-;school students and college students alike. In April and May, 29 schools participated in an outreach program where they toured the bridge, learned about construction careers and made glass mosaic tiles to be installed on an abutment of an overpass on the north approach.

|

| EDWARDS |

The brainchild of Figg chief executive officer Linda Figg, the program originally was meant to last two weeks and involve a few schools, but was extended by popular demand, says Denny Perrier, a field agent for the North Central States Regional Council of Carpenters. Perrier volunteered the council’s facilities for the program. “We had apprentice carpenters and journeymen come in and discussed operations ongoing on the bridge,” he says. “We [also] had operating engineers, laborers and cement masons come in.”

Meanwhile, Roberto Ballarini, a civil engineering professor at the University of Minnesota, is leading a team of graduate students in using advanced finite element modeling techniques to analyze the two gusset plates that National Transportation Safety Board investigators say were fractured in the old bridge. NTSB is expected to release a full report on the collapse by year’s end.

Should the analysis uncover gusset problems tied to excess loads or other factors, it could trigger a widespread reanalysis of the types of loads steel trusses can bear, Ballarini says.

Post a comment to this article

Report Abusive Comment