The world’s first hybrid dozer will cost about $100,000 more, or 20%, than a comparable non-hybrid of the same size but will do more work and pay for itself in about two and a half years, say Caterpillar Inc. managers. Performance is tracking well in field trials, said the managers on June 23, as Cat rolled out the machine for press evaluation at the firm’s training facility in Edwards, Ill. The D7E starts production in October and carries a list price of $600,000, says David E. Nicoll, product execution manager. That is 20% more than the conventional D7R but 12% less than the next-highest model, D8T, he adds. “Some say it feels like it has D8 power,” Nicoll says.

Cat started work on the machine in the late 1990s to create a more efficient tractor with big-dozer power. But as emissions and energy concerns rose, the D7E’s cleaner, greener, diesel-electric drive took on even greater significance.

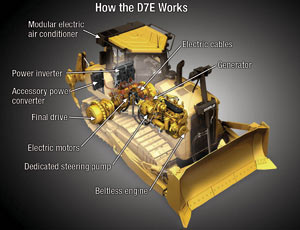

Though such a high price premium is unusual for construction machinery, Cat still expects the D7E to save users money in owning-and-operating costs and provide a payback primarily in fuel but also productivity, maintenance and other efficiencies of the hybrid drive. “It means the accountants are happy,” Nicoll says. Overall, the D7E is up to 25% more fuel efficient than the D7R. Cat measures fuel efficiency in terms of material moved per gallon of fuel. Electric motors replace a torque converter, effectively turning the transmission into a set of power cables.

The midsize dozer is not a high- volume seller in North America, but Cat hopes to change that with the D7E’s power and fuel economy. Last year, manufacturers sold about 2,000 D6-sized tractors in North America and 700 D8s, it says. In the D7-size range, only 300 were sold, but buyers worldwide took 4,000. Initially, the D7E will be sold in North America, Europe and Japan. The D7R will be available through mid-2010.

Taking away the trademark “high- drive” elevated sprocket was a tough decision, even requiring input from the chief executive’s office. “Caterpillar is not getting away from the elevated sprocket,” Nicoll explains, adding that larger machines will keep it. The powertrain setup enables the sprockets to perform tighter, locked-track turns. Cat says it is considering hybrids for other machines.

Early reviews are glowing. Daniel R. Plote of Hoffman Estates, Ill.-based Plote Construction Inc. says the D7E his firm is trying out is as handy as one of its D8Ts. “It is amazingly keeping up, pound for pound…and the fuel economy is incredible,” he says. ENR found the D7E easier to control and quieter than the D7R, in part due to the engine’s narrow operating rpm.

The machine is a breakthrough, but Cat may have missed an important opportunity to toot its horn over going green. When the concept was shown at CONEXPO 2008 in Las Vegas, Cat did not want to label it a hybrid because it does not store power onboard. Plote and others think it would do some good. “We are going green,” Plote says. “Unfortunately, our industry is probably labeled as anything but green.”

Post a comment to this article

Report Abusive Comment