Although the U.S. has only 5% of the world's total population, it has about 25% of the world's incarcerated population. The number of inmates has tripled since 1980, and with many correctional facilities overcrowded and in poor condition, the demand for new construction and renovation projects has been strong.

Annual construction starts for these project types reached $3.8 billion in 2007, according to McGraw Hill Construction Dodge data. Since the global financial crisis, starts have slowed to about $2 billion a year, likely due more to financing challenges than slackening demand. In fact, Dodge data shows a current backlog of almost $5 billion in deferred or abandoned projects.

|

| JONES |

CasaFlex, a patented system for facility design and manufacturing created by Mexican architect Carlos Garciavelez y Cortazar (CGV) and implemented in close partnership with ICA, Mexico's largest contractor, provides a compelling picture of what future solutions could look like.

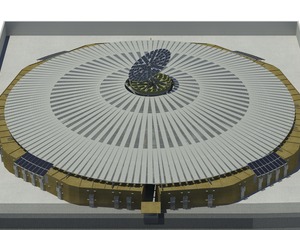

From its new, state-of-the-art precast factory near Mexico City, CasaFlex can produce up to 50 cells a day from a flexible menu of modular designs developed by CGV and all configurable in BIM. The cells, cast as full units in molds and installed on precast platforms, can be stacked several stories high, with standardized railings, stairs, windows and doors. Architectural metals provide sunscreen coverings with the other design elements that complete the package. Special and support spaces also can be created from standard precast elements. Thus, a wide variety of complete correctional facilities, including furniture and fixtures, can be produced quickly and efficiently.

Using CasaFlex, CGV and ICA recently completed two new advanced security prisons in Mexico for 2,520 inmates, demonstrating that a prison that would traditionally take 24 months to execute can now be completed in just 16 months. And under a public-private-partnership contract with the Mexican government, ICA also operates and manages the facilities, providing a uniquely complete solution. CasaFlex plans to expand into many more markets, including housing and schools.

Transformative Ideas

While commonplace among industrial corporations, virtual design and manufacturing processes are still in their infancy in the AEC industry. Although not glamorous, the application of these principles to correctional facilities may provide enough scale and skill-building to leapfrog us into more widely relevant residential, institutional and commercial project types.

Companies such as ICA and CGV are building a formidable competitive advantage through bold capital investments in digital design and manufacturing innovations that can quickly capture huge market share, leaving traditional competitors months or years behind. Digital technologies will continue to transform our industry at an increasingly rapid pace, providing an unprecedented opportunity to establish new business models and deliver projects in astonishing ways.

Stephen A. Jones is a senior director with McGraw Hill Construction. He frequently speaks and writes about technology and the construction industry. He can be reached at steve.jones@mhfi.com.

Post a comment to this article

Report Abusive Comment