When major owners stepped up and starting requiring contractors to improve safety, they got results. At its national conference, the Construction Users Roundtable announced plans to help improve construction industry productivity, as well.

CURT plans to work with the National Institute of Standards and Technology to implement recommendations from the National Research Council study published last summer. A key initiative is establishing a “universal metric on measuring productivity,” said CURT President Egon Larsen, manager of construction engineering at Air Products & Chemicals, Allenton, Pa. CURT will help NIST collect the data needed to determine this metric.

LARSEN

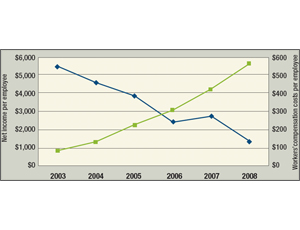

Frank MacInnis, chairman of EMCOR Group, Norwalk, Conn., showed metrics demonstrating how safety and productivity “go hand in hand.” As income per EMCOR employee has gone up, workers’ compensation costs have gone down. “It is extremely expensive to have unsafe working conditions,” he noted.

MacInnis also presented data about the high cost and large number of changes made in the construction phase. CURT also plans to work on this problem—from the point of view of the inefficiencies prevalent in hand-offs to construction. The construction team needs engineering, equipment and materials on time, and “the trend is getting worse, not better,” Larsen said.

The conference on Nov. 16-18 drew nearly 450 industry professionals to Lake Buena Vista, Fla., down 10% from 2008. CURT has “survived and thrived” during this historic downtown by being “nimble and flexible,” Larsen said. Tactics have included virtual meetings and organizational changes, including extending CURT internationally.

CURT lost owner members this year from recession-battered industries such as automotive and banking but replaced the numbers from other sectors. “By the end of December, we may have more than the 60 owner-members we had last year,” Larsen said. CURT has identified and will seek new members in markets such as health care and higher education, “where there are owners with large construction budgets” who would share similar goals.

MACINNIS

Larsen announced a new policy for CURT associate members. “We want to stay an owner-focused organization,” so the ratio of owners to associates will remain four to one, he explained. But associate members, which can be contractors or specialty contractors, will be selected to serve a two-year term, with half up for renewal each year. Associates can apply again at the end of each term. “It will be competitive,” but that will keep associates active and give those who have not been able to commit time to the organization a “graceful way to bow out,” Larsen said.

Forecasting Tool

Although labor now is plentiful, CURT members recognize the industry faces long-term shortages. As a result, CURT commissioned a Web-based data-collection and forecasting tool, managed by the non-profit Construction Workforce Development Center. Daniel Groves, CURT’s director of operations, said the demand side of the model has been active for about nine months, and the supply side, reworked to be more user-friendly, was launched in November. Owners and contractors who enter data at www.cwdcforecasting.com can run forecasts at no charge.

There currently are 119 projects in the model, ranging from short-term maintenance projects costing a few million dollars to major projects worth several billion dollars. CURT is working with owners who have agreed to input about 600 additional capital and maintenance projects, says Groves.

One undisclosed state will launch a statewide application of the model in January 2010, and CURT is working with a second state that will launch its model later in 2010. The states want to use the model to augment or replace their current forecasting data, which rely on statistical trendlines rather than project detail.

Post a comment to this article

Report Abusive Comment