On a cold, gray day in late March, the mountains on the drive to the Yusufeli hydroelectric dam project site in northeastern Turkey seem ominous.

With the highest of these rising more than 3,000 meters above sea level—some of them snow-capped—the jagged rock formations look stark and imposing, the type only a trained professional should attempt to cross.

About an hour’s drive outside of the city of Erzurum, the impoundment at the double-arch concrete dam, located in the midst of these mountains, is slowly filling with water from the Çoruh River, a process that will continue into the fall of this year. More than two decades in the making, the Yusufeli dam is a visual stunner. Rising 275 m high, it is the tallest dam in Turkey, and fifth-tallest in the world. When fully operational by the end of 2023, its power plant will have the capacity to generate 1.89 terawatt hours of electricity per year.

The entire project is valued at $1.8-billion. Limak Construction, part of the Limak Group, a Turkish conglomerate, leads construction.

Austrian firm Andritz Hydro is providing the hydroelectric design, installation and equipment, and South Africa-based ARQ Consulting Engineers is assisting with design, thermal analyses and modeling as well as final analyses, with Limak to determine if the dam is performing as predicted as it fills. The Turkish General Directorate of State Hydraulic Works (DSI) is the owner of the project, which broke ground in February 2013, with concrete placement for the dam beginning in 2018.

The project team’s responses to the challenging topography, strict time limitations and the huge amount of concrete involved have led to a significant step forward in the technical understanding of dam engineering, says Quentin Shaw, a director at ARQ who also is vice chairman of the concrete dam committee for the International Commission on Large Dams (ICOLD). “I would call it evolutionary rather than revolutionary,” he says, but adds, “There’s a huge amount of information to publish” in technical journals and bulletins about what was learned at the dam project.

Nevertheless, as with other dams in the region, the project has been controversial. People who have lived entire lives in the Artvin valley, nestled in the hills upstream of the dam, are watching homes and livelihoods disappear as water rises in the reservoir and in surrounding areas each day. The government has offered local residents funds to relocate to a newly constructed town a safe distance away from their washed-out homes and businesses, but local opposition to the dam has remained strong.

The construction team worked with mountaineers and erected cable cranes to bring equipment to the site under sometimes harsh weather conditions.

Photo courtesy of Limak

Photo courtesy of Limak

Push for Renewable Power Sources

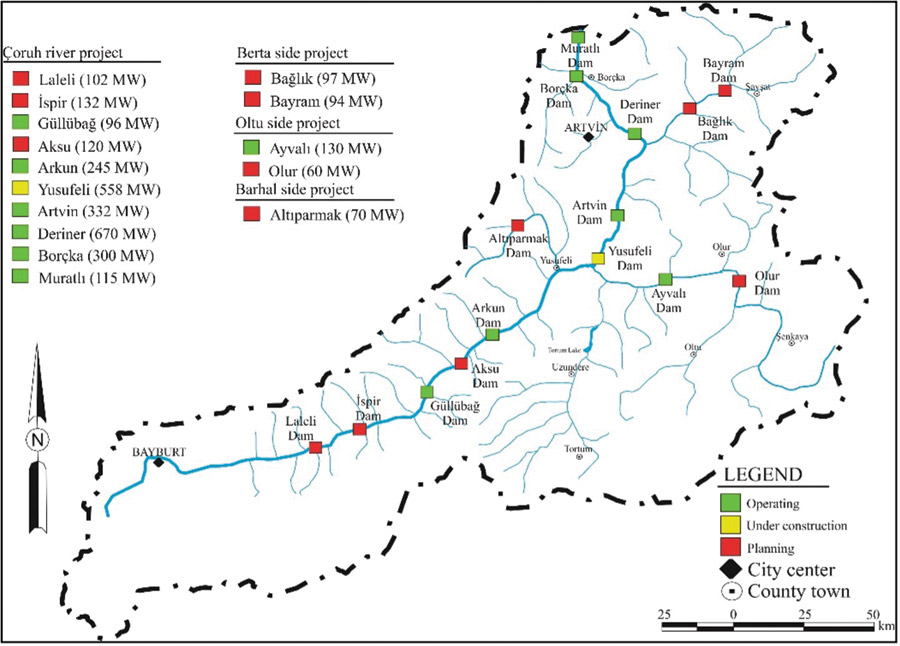

Yusufeli dam is one of 17 hydroelectric dams built, under construction or planned for the Çoruh River District, in the Black Sea region of northeastern Turkey. Located in a narrow, V-shaped section of the valley between the existing Artvin and Ayvali dams, it will store 2.2 billion cu m of water when full. The power plant within the dam contains three 186-MW turbine units that will use energy from the river to generate electricity.

The projects are part of the Turkish government’s comprehensive strategy to generate more domestic energy and become less dependent on outside sources. The Artvin district has the capacity to store up to 6 billion cu m of water, says Celal Tokalak, DSI area manager, who spoke through a translator at the project site. Yusufeli dam will be operated to work in coordination with other dams along the Çoruh, such as Artvin dam—which also has a 2-billion cu m capacity—to be able to provide more electricity when needed, he says.

Over the past two decades, Turkey’s population growth and economic expansion have fueled a push for more domestic sources of energy to replace oil and gas imports now meeting much of its demand, according to a 2021 analysis by the International Energy Agency. Renewable electricity generation—which includes power from hydroelectric dams—has nearly tripled over the past 10 years, making up 44% of the country’s power generation in 2019, says the organization.

Limak Chairwoman Ebru Özdemir says the project is part of the global shift toward energy sources that are less carbon-intensive. “Turkey is fortunate to have [abundant] natural resources like hydro, solar and wind, making our country an ideal location to become an important player in renewable energy,” she says. “At Limak, this is where our focus is at.”

The Yusufeli dam is part of a network of hydroelectric dams throughout the Artvin Valley region, with some that are still in the planning stages.

Map courtesy of Limak

*Click the map for greater detail

Overhead Conveyance

Excavation took longer than expected due to the area’s complex geology, which challenged crews in their efforts to gain access for construction and deliver equipment to the project site. At times, snow and fog would decrease visibility, further hampering team productivity and safety. Several overhead conveyor lines were erected to deliver equipment—from bulldozers to cranes—to the site.

Construction crews blasted spiral tunnels with a 17% incline through the rock well above the crest, the highest point of the dam, to get down to where the structure’s foundation would be constructed. The tunnels also provided access to the dam’s crest through a benching system carved out of the rock. During this process, all equipment was securely fixed to the surface with ropes. The entire team brought construction equipment and machinery to be able to begin excavation to reach the foundation level.

Limak worked with local professional mountaineers as a precautionary measure. The slope between the dam’s foundation and the rock above it was steep, with loose rocks and boulders that could easily fall on work crews below if not secured, Shaw says.

The construction team used a conventional vertical construction process to build the concrete monoliths from the ground up, topped with cantilevered viaducts.

Photo courtesy of Limak

Because the slopes of the rocks at the river banks were nearly vertical, Limak installed a system of post-tensioned anchors into the rock itself to provide structural support during the excavation process. The anchors were installed to be able to bear tensioning loads of up to 240 metric tons, says Fatih Çevik, the contractor's deputy general manager and technical coordinator of the Yusufeli dam project. The anchors “ensured the stability of the excavation slopes that constitute the foundation of the dam” and thus served as a means to strengthen its overall structural integrity, he says.

Anchors were installed as work went along, above the areas where excavation work was taking place. Each anchor consisted of seven high-strength steel wires first placed into boreholes and bonded to the rock, and an anchor head made of reinforced concrete cast over the drill hole. Limak installed more than 6,000 post-tensioned anchors on the rock masses around the dam.

“On a site like this, you can’t excavate too quickly because you’re upsetting rock,” Shaw notes. “You have to make sure you’re not overstressing the rock and getting instabilities.” The laborious process of excavation followed by installation of the anchors, step by step, took longer than expected, he adds.

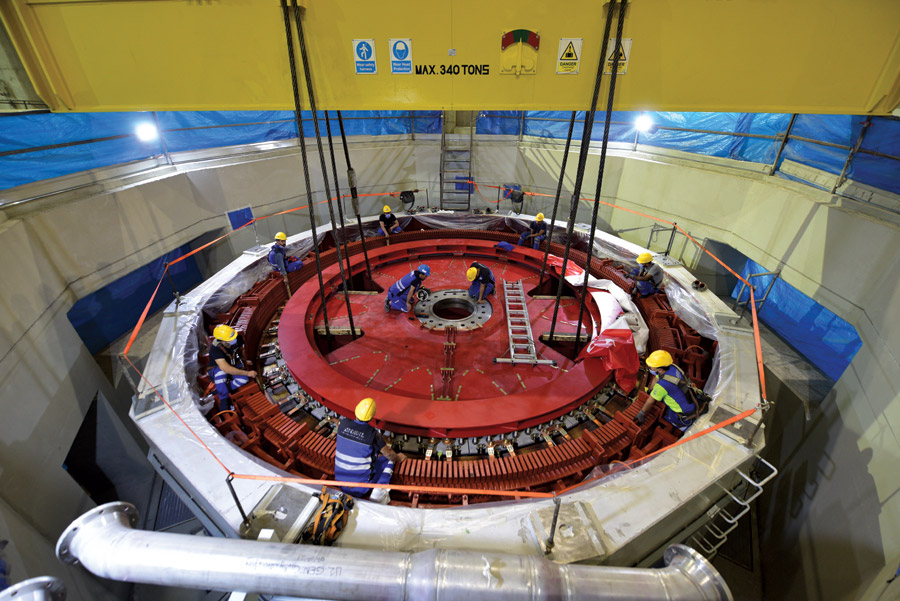

The dam includes three shafts that each hold one 189-MW Francis turbine unit. Collectively, the units will generate up to 558 MW of power. Photo courtesy of Limak

Getting Concrete Temperatures Just Right

To make up for the extra excavation time, the project team sought efficiencies in placing concrete for the dam’s main arch. One of the project’s biggest takeaways is the team’s greater understanding of how to place concrete effectively and efficiently in a tight timeframe, according to team members. DSI wanted construction of the dam, which contains 4 million cu m of concrete, to be completed within two years. Limak came close to that goal, wrapping up dam work in 30 months, Çevik says.

One solution was to place several concrete batching plants at the project site. Aggregate for the concrete was conveyed to the plants by the overhead cabling system.

The arch of the dam operates as a single mass curve of concrete, with its structure made up of 29 separate cantilevered formwork-enclosed concrete blocks. These were placed as individual vertical monoliths, compacted in gang-mounted immersion vibrators. The blocks were then grouted together at the joints.

Construction of the dam is leading to flooding in the surrounding upstream community, which has been the focus of much of the opposition to the project. Although a new town was built for about 2 million people who are expected to be displaced, many are unhappy to lose the only homes they have known.

Photo by Ugur Yildirim/DIA Images

Because concrete temperature naturally increases when water is mixed with cement, the team had to ensure that the mix was chilled enough to be able to place quickly but not so cold that the concrete would crack as it hardened. Additionally, the team had to account for natural creeping that occurs when concrete becomes misshapen due to consistent pressure, and then shrinks. If that shrinkage is not taken into consideration, the connections between the joints and cantilevers could separate. To be able to hold water without leaking, those joints need to be airtight, Shaw explains.

“It’s very tricky to get the timing all correct, so that you are not going to shock the concrete into cracking by cooling [too quickly] but still fast enough to keep the construction rate going,” he says. The concrete mixture also was low in water and consisted of 40% fly ash—a composition that is different than that described in the generic existing guidelines for concrete dams at ICOLD and elsewhere, Shaw says.

Shaw and Çevik are working on a journal article, including a bulletin for ICOLD, based on what they have learned about how to get temperatures just right for large concrete arch dams.

Construction crews bored more than 6,000 anchors into the rock (above and right) to prevent it from destabilizing.

Above Photo courtesy of Limak, photo right by Pam McFarland for ENR

Design Revisions

Because the site was so remote, the design team could not fully assess the rock’s composition until members were able to access it. Although a final design had been completed, the project team had to make adjustments once its members were able to get on site.

The final design anticipated the need for approximately 2.3 million cu m of concrete for a relatively shallow foundation on a mostly homogenous rock foundation. Geotechnical investigations revealed much more heterogeneity in tensile strengths that was caused by a complex network of joints. As a result, the design team, led by AQ Consulting Engineers, created a more sophisticated model that was based on actual site conditions. It also devised a cushioning system to create a more flexible transition between the high strength, highly elastic arch concrete and the lower strength, less elastic foundation rock mass.

Once filled, the dam impoundment will be able to hold 2.2 billion cu meters of water. The project is set to be fully complete by the end of 2023

Photo courtesy of Limak

History of Opposition

The dam has not progressed without incidents and headwinds. Four fatalities occurred over the course of the project, related to a traffic accident, according to a source at Limak. Two were Limak employees, two were from subcontractors. Although the source says the incident rate among 7,000 workers is a relatively low number, “our target is zero. We always reevaluate our standards after an accident.”

In the early 2000s, when planning for dams in the Artvin district began, U.K.-based contractors AMEC and Balfour Beatty/Foster Wheeler withdrew from the Yusufeli and Ilisu dam projects, respectively, citing pressure from environmental and human rights groups.

Limak executive Fatih Çevik and AQ Consulting Engineers director Quentin Shaw confer on site.

Photo by Pam McFarland for ENR

In a 2011 report submitted to the United Nations Committee on Economic, Social and Cultural Rights, opponents noted that although the proposed dams could affect more than 2 million people as well as threaten the biodiversity of the region’s wildlife, those communities were not included in planning or assessments performed about environmental impacts. As late as August 2022, Yusufeli shop owners were protesting the forced move to the new settlement because the district would be submerged by the dam.

Limak’s Özdemir says her firm has gone out of its way to support local residents, providing housing to people working on the project when needed. At its peak, some 7,000 workers were involved in dam construction, with as many as 6,500 staying at one time or another at housing facilities the firm provided. According to DSI’s Tokalak, the reservoir will eventually increase tourism in the district and could enhance regional development in the long run.

Meanwhile, the Yusufeli dam continues to fill. As of late May, water had reached a height of nearly 208 m.

The team is checking to make sure no cracking or discrepancies occur at the end of each of six stages of impoundment. When water reaches the end of stage four sometime in late summer, the hydroelectric turbines will begin running, Çevik says.

Shaw says caution is warranted with a dam of this size. A miscalculation could have devastating consequences. But so far, so good, he contends. “There’s been no surprises, no unexpected displacements, no plastic displacements, which is the big important one,” Shaw explains. “That’s what we look for and it’s all going extremely well.”

_ENRready.jpg?height=334&t=1686916833&width=640)

_in_Conowingo_Station_Cecil_County_Maryland.jpg?height=200&t=1671739394&width=200)

Post a comment to this article

Report Abusive Comment