When the city of Lenexa, Kan., this spring opted to move forward with a test pilot of “smart pavements,” (ENR 5/2-5/9, p. 10) it represented a step forward after nearly a decade of efforts for Integrated Roadways—not just for the company founded by Tim Sylvester, but for attempts to make roads smarter in an industry that has been focused on smarter vehicles.

“It’s been a whirlwind,” says Sylvester, whose Smart Pavement technology has since undergone a demonstration for Cisco and Ford Motor Co. in Detroit. The results included a partnership with Cisco, and “we ended up being part of [a keynote speech] where they were talking about digital infrastructure for the next generation of vehicles,” says Sylvester.

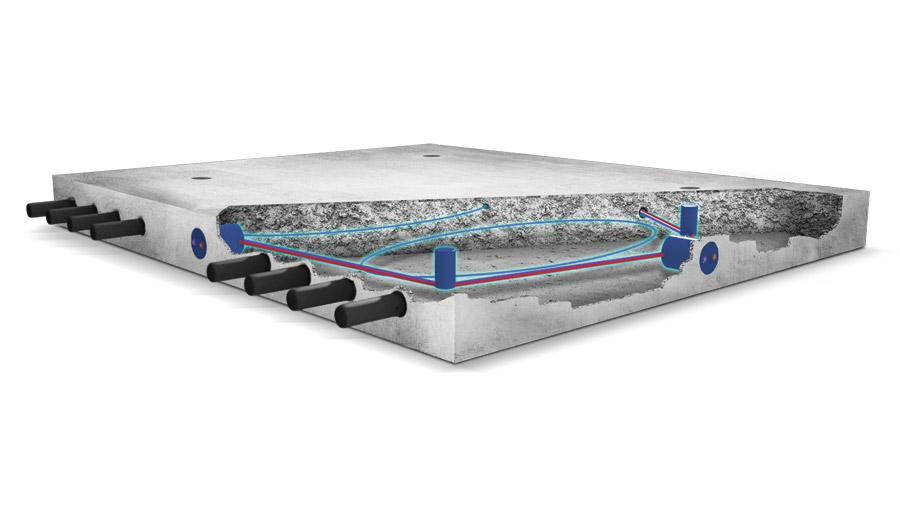

His system consists of precast concrete road sections embedded with digital technology and fiber optic connectivity. This enables traffic data collection through in-road sensors, Wi-Fi, 5G and more. Antennas in the expansion ports facilitate edge services, cloud access and wireless electric vehicle (EV) charging. It was tested on Brighton Boulevard in Denver in 2018, and on a rural Colorado road.

“Once the technology is refined, and they can have data reliably back to owners or facility stakeholders; this is a very useful technology,” says Andrew Garton, Colorado Springs manager for WSP, which participated in the pilots. The remote road site did have issues with connectivity and electricity costs that need to be addressed, he says.

“This [pavement] has potential to provide real-time data for traffic volumes and better manage facilities,” he adds. “There are opportunities to be utilized for additional benefits such as over-the-road charging.”

Smart Roads is one of various technologies aimed at helping roads be more than passive receptors for smart vehicles or external data collection systems. In Europe and the U.S., roads that honk, glow, collect solar energy or—considering the Biden administration’s concerted push for EVs—can charge them, have undergone tests that show their potential and pitfalls.

The Smart Pavement System consists of precast concrete road sections embedded with digital technology and fiber optics.

Photos Courtesy of Integrated Roadways

Electrifying Future

Efforts to escape the constraints of tethering EVs to chargers for hours led to the development of wireless technology, starting with static systems. An early entrant was U.S.-based WiTricity Corp., founded by the Massachusetts Institute of Technology in 2007.

The system incorporates magnetic coils in pads that sit beneath parked vehicles, wirelessly charging their batteries. The technology has attracted interest, including from Germany’s Siemens A.G., which this June acquired a minority stake in WiTricity for $25 million. Siemens valued the potential European and North American markets alone at $2 billion by 2028.

Among pioneers of dynamic wireless charging was the Korea Advanced Institute of Science & Technology, which ran two electric buses on 24 km of energized highways in Gumi, South Korea, nine years ago. In France, the Renault car company in 2017 tested two EVs on a 100-m test track in Satory, built by the Vedecom research institute using a charging system developed by Qualcomm Technologies. Germany’s IPT Technology has tested its Primove dynamic systems on a range of vehicles in Germany and Belgium, claiming more than 90% efficiency.

“Where we are today is a pinnacle point.”

-Ron Williams, Jacobs senior vice president and general manager, People & Places Solutions Americas, on the evolution of smart roads

Wireless battery charging of moving EVs is now ready for commercial rollout, believes a technology developer, following road trials in Italy. The company, Israel-based Electreon Wireless Ltd., is targeting bus routes as early adopters, but hopes EV owners will eventually also escape the need for the patience of plug-in charging.

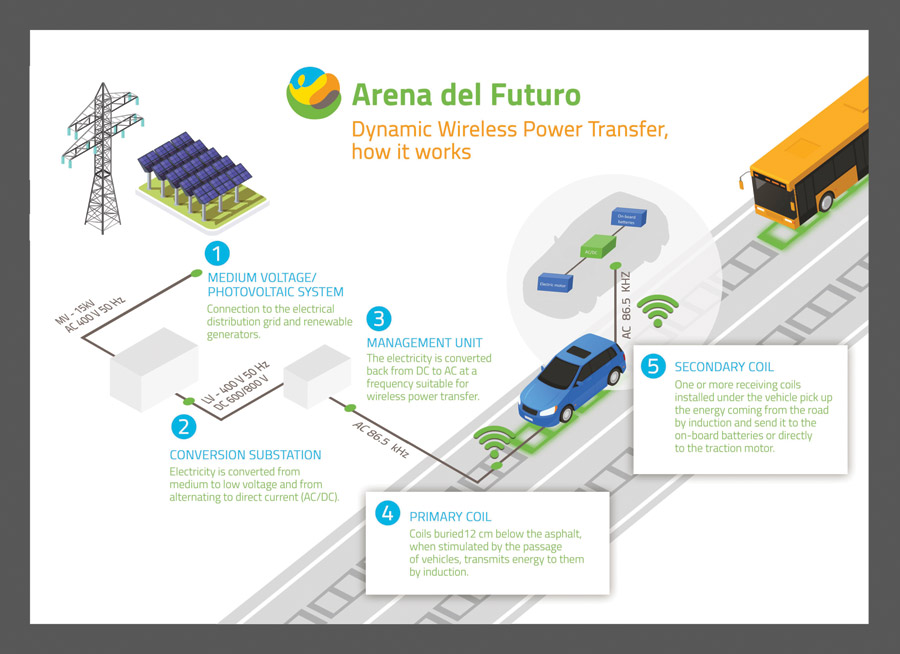

Starting late last year, the “Arena of the Future’’ dynamic charging project took place on a roughly 1-km-long closed track next to the A35 Brebemi motorway in Brescia, east of Milan, Italy. Electrified magnetic coils beneath the road’s asphalt surface energized matching coils under moving test EVs by induction to charge their batteries.

A test bus toured the circuit for four days, scarcely losing battery charge, says Oren Ezer, CEO of Electreon, which he co-founded nine years ago. During four hours on the circuit, the battery on a small Fiat 500 car went from 22% charged to 48%, adds a spokesperson.

Electreon has invested $38 million worth of backers’ funds developing the hardware and software for dynamic, semi-dynamic and static systems, says Ezer. The system “can actually do the same, or in some cases, better performance” than the wired option, he adds. Electrifying about 15-20% of a route along with static wireless charging at each end can cut battery size by up to 90%, claims the company.

For the Italian trial, a local contractor took two days to embed the coils in different types of asphalt surfaces at the 1-km “arena,” according to Electreon. Using conventional construction equipment to dig and equip a 10-cm-deep, 1-m-wide road opening typically costs around $1 million per lane km, says Ezer. He estimates the life of coils to be about 10 years.

“The technology seems to work well and is more or less on the same maturity level as other e-road solutions,” says Stefan Hörnfeldt, business development coordinator at NCC eRoad, a unit of the Swedish contractor NCC A.B. The company is advising on dynamic trials funded by the Swedish Transport Administration (Trafikverket) using Electreon technology on Gotland island. Starting two years ago, the “Smartroad Gotland” project ran vehicles on a 1.65-km highway section in the city of Visby.

The Electreon system is set to debut in Michigan after successful trials in Europe.

Image courtesy of Electreon

*Click the image for greater detail

“We showed that the vehicles were able to charge while driving at 80 kilometers per hour,” explains an Electreon spokeswoman. Able to function in the day and night, in rain and snow, the technology was also robust, she adds.

“The trial has not been finally evaluated yet,” says Hörnfeldt. “There is still some work to do concerning standardization, industrialization and the business model.” He believes the potential for e-roads to be huge, but still difficult to quantify. The technology is best suited for “big, high-traffic roads with a lot of heavy vehicles outside urban areas or in areas where it’s difficult to set up stationary charging,” he adds.

NCC is exploring possibilities at industrial and transportation sites. And it will likely bid for Trafikverket’s planned electrification along the roughly 20-km section of the E20 highway between Örebro and Hallsberg. “They haven’t decided upon what technology to be used yet,” says Hörnfeldt. But “this could be our first ‘real’ commercial contract.”

This year, Michigan took a big step toward its planned transition to all-electric fleet operations with the announcement of its plans to pilot Electreon’s wireless inductive charging technology on a 1-mile road stretch. The state’s chief mobility officer, Trevor Pawl, notes that EV fleet owners “can’t really afford to have their vehicles sit at a charging station for 50 minutes or longer.” To receive a charge from the inductive technology, EVs must be outfitted with a special beacon from Electreon.

The Michigan Dept. of Transportation will provide $1.9 million in funding toward the pilot project, with Electreon matching that funding by 25% under contract. The project is expected to publicly launch in 2023. NextEnergy, DTE Energy, Kiewit and Jacobs Engineering Group have all been tapped as collaborators. Ultimately, the vision is for the electric roads to support and enable charging for any type of vehicle, explains Electreon Vice President Stefan Tongur. “We are calling it an open-charging platform because that helps with higher utilization of the infrastructure,” he says, compared to the energy required for stationary charging platforms. “Once we build them for buses and delivery trucks, then you can open the system up for the public and it will make sense,” he adds.

Ron Williams, Jacobs’ senior vice president and general manager, People & Places Solutions Americas, says such technologies will transform the market. “We have confidence given Electreon’s history that it will work,” he says. He cites other intelligent infrastructure efforts in Georgia, Nevada and Pennsylvania. “If I were a junior engineer I would be really excited—it’s a fundamental shift in transportation going forward,” he says. “Currently where we are today is a pinnacle point.”

The Infrastructure Investment and Jobs Act provides $7.5 billion for the development of the national electric vehicle charging network, which is estimated to need around 500,000 stationary chargers to meet the consumer transition to EVs. The wireless charging system could help accelerate businesses’ conversion to electric vehicles, says Pawl.

“If we can maximize those situations, it can help the world switch to electric faster, unlock new revenue channels for states and cities and also help fight climate change,” he says.

The company’s technology was tested on a closed test site in Italy using various types of asphalt pavement.

Photos courtesy of Electreon

Sunny Days

The U.S. has the largest public highway system in the world, boasting more than 4 million miles of paved roads, according to the U.S. Dept. of Transportation. As the global energy transition accelerates, and public agencies invest in renewable energy infrastructure, the French engineering giant Colas is aiming to turn roadways into sources of energy by installing a layer of solar panels on top.

Launched in 2015, Colas’ Wattway solar panels are composed of photovoltaic (PV) cells embedded in resin that can be glued directly to existing infrastructure “without earthworks,” explains Laurent Le Boulc’h, managing director of sustainable infrastructure and smart mobility. Installed panels capture solar energy that can directly power equipment or be added to an electrical network, says Le Boulc’h, “thus providing an innovative solution to produce renewable energy.” Wattway is suited for smart grid applications, he says, to “produce energy close to its place of consumption or even off-grid.”

In rural areas, “Wattway can be used wherever it is difficult and costly to hook up to the electricity grid,” adds Le Boulc’h, creating a “local distribution network with limited losses and a long-lasting source of renewable energy.” The lifespan of the panels is up to 15 years, he says.

“You always want innovative ideas to succeed. But even when they don’t, these tests help us understand …

But after five years of research and development tests on more than 70 sites around the world, including the U.S., Canada, Holland, Italy, Dubai, Japan and France, the company has not found a roadmap that makes economic sense on a large scale.

In December 2016, Colas unveiled the “world’s first solar road” in Tourouvre-au-Perche, France, a pre-pilot investment in Wattway technology by the country. With a more than $5 million installation price tag financed by the country’s Ministry of the Environment, the project included a roughly half-mile stretch of road covered with 2800 of Colas’ durable Wattway panels. The road was expected to generate as much as 150,000 kWh a year while enduring the elements and heavy traffic flow. However, with little sunshine in the region, the project underperformed in relation to its installation cost over a two-year trial period. The system ran into wear and tear that affected its ability to absorb solar power, and the country pulled the plug on expanding the idea.

In the same month, Colas launched a version of the project in Georgia that seemed to show more promise, installed on a 50-m section of the state’s 18-mile Ray C. Anderson Memorial Highway, which is also known as The Ray. Completed and installed in partnership with the Ray Foundation, a highway innovation nonprofit, the Georgia Dept. of Transportation, and Reeves Construction, a subsidiary of Colas, the section generated an estimated 7,000 kWh annually, enough to provide electricity to a nearby welcome center. A second version is in the works, according to the Ray Foundation.

It didn’t take long for Wattway’s prospects to dim under the stress of weather and wear, and the original 50-sq-m installation of panels evidenced frayed edges and other deterioration. “The roadside environment is remarkably harsh,” says GDOT operations director John Hibbard. “Whatever we consider has to survive in that world.” A 2019 upgrade with new panels boasting a 21% improvement in performance—to a 144 W peak per sq m—did not provide a comparable improvement in overall durability.

“We don’t see any applicability for it right now,” Hibbard says.

Similar durability woes have befallen The Ray’s tests of 3M-developed pavement markings, manufactured with microcrystalline ceramic beads that are designed to be more visible to both human and autonomous vehicles. Hibbard says the markings, deployed along 13 miles of The Ray in 2019, are relatively inexpensive and popular among motorists, but also require frequent replacement.

In 2014, a pilot solar walkway project helmed by the Idaho-based startup Solar Roads was set to go forward at a Route 66-themed rest stop in Missouri, with hexagon-shaped panels installed in concrete. But after initial buzz, a $100,000 grant to produce a prototype for the Federal Highway Administration and a $2.2-million crowdfunding campaign, the company couldn’t deliver on the durability of the panels and backed out.

In general, despite all the cool-sounding road technologies, the basics should not be forgotten, cautions Jagannath Mallela, managing director with WSP USA. “A safe, beautiful smooth driving surface is the first priority,” he says. “I see technology being embedded, but always wonder about the long-term maintenance and operation costs.”

Hibbard says simply trying out technologies in a setting such as The Ray benefits the industry.

“We’ve enjoyed a great relationship with The Ray, and it’s fun that we’re able to try things out and see how they work,” he says. “You always want innovative ideas to succeed. But even when they don’t, these tests help us understand how they perform, what benefits they might provide and what’s needed to make them viable.”

The idea is still a sound opportunity to give “a second function to our road infrastructure by turning solar energy into electricity,” says Le Boulc’h. Smart roads are about sustainability, he says.

“Before talking about smart at Colas, we talk about sustainable infrastructure,” he says. “Our main objective is to promote preventive maintenance instead of curative maintenance. It is one of the strongest levers to reduce the carbon footprint of infrastructure—especially the existing [infrastructure].”

A solar roadway technology tested in France (above) and the Netherlands showed promise, but had issues with weather and durability in Georgia.

Photos courtesy of Colas

Honking and Pulsing

HP Lubricants and Leo Burnett India in 2017 initiated a system called Roads That Honk on the Jammu-Srinagar Highway in India. Roads That Honk adopts SmartLife pole technology at sharp curves and hairpin bends with advanced networked devices that combine wireless technology, radar systems and an anti-collision warning system, all powered by solar PV modules.

The police department overseeing the 63 miles of the Jammu-Srinagar Highway belt has experienced roughly two to three vehicular incidents daily. Since the 2017 installation of the SmartLife pole, the department believes this number has reduced significantly.

The system transmits an electromagnetic wave in 24 GHz frequency range (K-band) which measures the frequency shift of the reflected electromagnetic wave. The frequency shift is caused by the Doppler effect of the moving target on the electromagnetic wave. As speed between the radar sensor and the target increases, the detected frequency shift also increases and alerts any driver coming around a curve.

In a press release, Rajdeepak Das, chief creative officer with Leo Burnett, South Asia, said: “We are glad to have been behind an innovation that harnesses the power of technology, and uses radar signals to [alert] drivers. We are confident Roads That Honk will significantly reduce accidents and save several lives every year.”

In France, another application is aiming to improve safety by monitoring the temperature, humidity, dew point and frost point of a road. The city of Grand Lyon in France uses an advanced data acquisition system for winter service operations at nine locations. The system provides real-time knowledge of phenomena that can be localized and fleeting, requiring larger deployment and a dense network of data collection points to secure accurate data, and enrichment of weather forecast bulletins with real-time data. The technology’s embedded sensors measure road surface temperature, outside temperature and humidity.

The embedded sensors and acquisition nodes communicate real-time information through the 2.4-GHz acquisition network to the HIKOB GATEWAY that is connected to an IP network.

Isabelle Fontany, a Grand Lyon innovation and development engineer, says “the system provided by HIKOB helps us to gather more accurate measurements about weather conditions and to better understand the local situations.”

Katie Zehnder, technology department leader with HNTB, sees other smart road technologies ranging from self-healing pavements to digital twin models to pavements responsive to floods, hurricanes and other natural disasters. She compares the technologies to that of cellphones: “They’ll be able to do what we are not even thinking about right now.”

Mallela cites more possibilities, such as energy harvesting, embedded striping to inform vehicles in low visibility, lighted pavements, embedded sensors for red lights and curbside management. “You will have a pavement connected with vehicles; an integrated vehicle-highway system,” he says. “The future is no longer just about roads. Roads [and vehicles] will co-evolve.”

For Sylvester, with Integrated Roadways, the past decade has seen a sea change. He recalls “the early days where we’d talk to public agencies about digital infrastructure and they’d chuckle and say ‘maybe in 50 years, but not in my lifetime.’”

“Now,” he says, “we sit down with them and they say, ‘We need it yesterday, how soon can we get it installed?’”

Post a comment to this article

Report Abusive Comment