Delivering a project for a public agency in the U.S. can feel like a strange, parallel world compared to the commercial construction sector. While contractors, engineers and design firms now work through the details of moving their own shops from established 3D BIM frameworks to 5D and digital twin-based workflows, designs and bids for public projects are still happening in 2D, with a lot of time spent recreating models and schedules to fit older standards. This has been frustrating for agencies, designers and contractors alike, but recent efforts to advance standardization, plus funding tucked away in the recently passed $1.2-trillion Infrastructure Investment and Jobs Act (IIJA) may spur the broader advancement of digital processes on public infrastructure work.

“We’ve been encouraging the term 'digital project delivery,'” explains David Unkefer, senior construction engineer with the Federal Highway Authority. “which means state DOTs push forward their ability to take a project digitally from beginning to digital as-builts.” Unkefer is quick to point out that much of what FHWA does is advisory, and the way transportation is organized in the U.S. leaves it to states to step up and seek the necessary grants and aid to advance these digital transitions. But a few state DOTs have been pushing the boundaries of digital delivery, and Unkefer says it is likely that other states will begin drafting in behind them.

The Utah Dept. of Transportation is moving projects through design and construction entirely in 3D, saving time and reducing the time contractors need to spend redoing models after winning bids.

Image courtesy UDOT

*Click on the image for greater detail

There have been some steps taken at the national level toward standardization. In 2021, the American Association of State Highway and Transportation Officials (AASHTO) officially endorsed the use of the IFC file formats, an open standard for interoperable file transfers through different software platforms for design, construction and fabrication.

But agencies embracing IFC is just the first piece of the puzzle, says Unkefer. “AASHTO has adopted one important standard, IFC, so we’re expecting proprietary software [platforms] will begin to use IFC and other important standards…Then we can share data more seamlessly providing for much greater productivity,” he says. A spokesperson from FHWA adds that while "FHWA promotes the use of open data standards, while not mandating them," it has, in the past, "done research and a global benchmarking study that confirmed the importance of open standards such as IFC."

There is also good news for technology adoption in the form of provisions in the IIJA. Section 13006 has a provision for “accelerated implementation and deployment of advanced digital construction management systems.” This provision establishes a program to bring more advanced digital delivery methods and technology into public projects, including interoperability, throughout the construction life cycle.

“There’s definitely an expectation in Congress that states are already doing this more than the actual numbers bear out,” says David McKenney, vice president of government relations at Bentley Systems. But while process issues still need to be solved at the state level, McKenney sees the Infrastructure Act as one way to gets states to increase their usage of digital project workflows. “We do think the IIJA is a good step forward to help address those barriers.”

FHWA’s Unkefer says the IIJA mandate to boost adoption of these new technologies could take several forms, but may be delivered to states through grants similar to FHWA’s Accelerated Innovation Deployment (AID) demonstration program. According to a spokesperson for FHWA, the agency will manage the new Advanced Digital Construction Management Systems Program, which under the IIJA will be provided with $20 million annually over five years.

But getting state departments of transportation onto modern digital workflows isn’t going to come from a purely top-down approach, he adds. Instead, there are several DOTs that are blazing a path for others.

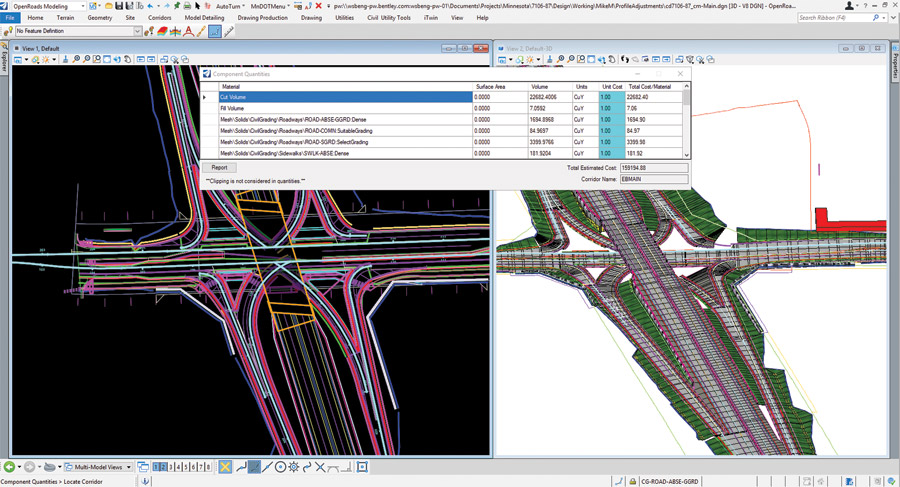

Image courtesy WSB

*Click on the image for greater detail

The 3D Model Is the Contract Document

The Utah Dept. of Transportation has emerged as a DOT willing to try out many newer methods and approaches in project delivery, including techniques that have since entered wider usage such as accelerated bridge construction. But a recent initiative situated earlier on in the process—using a digital delivery approach during design and bidding—has drawn praise from contractors. Working from its own internally developed standards, UDOT has already bid out several projects using this approach.

“We’ve had a few projects that we were able to move through where the digital document is the legal contract document,” explains Carlos Braceras, UDOT executive director. “It goes through design as a 3D model, and then that goes right to construction, which is then built as a 3D model that comes back to the statewide [model library]. We have one source of truth.”

Image courtesy WSB

*Click on the image for greater detail

While model-based project delivery isn’t a new concept, it’s a big step forward for a state DOT to fully embrace it, Braceras says. “We need to demonstrate to Utahns that we can do [these things effectively]. We need to take risk out of the projects, [avoid needless] redesign. It’s all about this shared mission.”

So far, UDOT has awarded and constructed 15 projects with the model as the legal documents and “nine without cutting sheets,” says George Lukes, UDOT standards and design engineer. Under this process, contractors get the design file in a format compatible with their own 3D workflows, saving time that previously would have been spent rebuilding the entire model from 2D documents.

“Some of our prime contractors took that file and put it in their software, and it took only two or three days in a 24- or 26-day advertising period [for the bid],” Lukes says. “They were then able to do a lot of their logistical planning instead of wasting time recreating the model.” With more time to plan out and optimize haul roads and equipment staging, contractor bids were now coming in 20% to 30% below the state engineer’s estimates, Lukes says. Bids from contractors not using this digital design workflow were only coming in 4% to 5% under. Despite rising materials costs and other factors that have driven up bids in recent years, Lukes says that most if not all of the 15 projects using digital delivery ended up with bids that came in under estimates.

Image courtesy WSB

*Click on the image for greater detail

Rather than dragging contractors along with UDOT’s new workflow, Lukes says it was the state’s biggest contractors who were clamoring for more 3D model-driven processes. And it was thanks to a few FHWA grants that UDOT was able to get its own systems build up to handle it.

There are still some hiccups. Many subcontractors and fabricators still work in 2D, but Lukes says the contractors have stepped up to handle those model conversions for now. He also notes that UDOT is setting this process up as a model to other public agencies. “People can see that Utah has done it. We’ve shown the efficiencies and the ability to push the data out—that’s the bigger deal.”

Following AASHTO’s guidance on adopting IFC file formats and other standards will also help in the long run, Lukes says. Once that interoperability is in place, it won’t matter, for example, that UDOT works in a GIS-based system while a designer works in Bentley Systems products and a contractor uses Trimble software to plan out their work. “As long as we get the data and the others get the data they need, we don’t have to worry about the tools—they can use whatever is easiest for them.” he says.

A Model Project Turns Heads

“They were able to accomplish at the 30% design review what normally would not be known until the 90%.”

Greg Hruby, CAD Supervisor, MnDOT

At first glance, the TH 169 highway interchange realignment in Elk River, Minn., doesn’t seem all that notable. Five at-grade intersections converted to highway interchanges with associated utility relocations make for a fairly standard project. But engineer WSB decided to show the Minnesota Dept. of Transportation what can be accomplished with 3D-model driven design and using a constantly updated digital twin.

“It’s a three-mile corridor, but there’s over 60 miles of utilities,” explains Peter Muehlbach, senior director and transportation manager for WSB. “We were able to identify those early on, and get that work done a year early.” WSB modeled the entire project in Bentley OpenRoads, and continuously updated a digital twin for review by MnDOT. It’s the first fully 3D project of this kind that MnDOT has overseen, and it’s already drawing fans within the agency.

“They were able to accomplish at the 30% [design review] what normally would not be known until the 90%,” says Greg Hruby, CAD supervisor with MnDOT. The detailed 3D models allowed for utility relocation and land acquisition to be sorted out much earlier in the process, adds Hruby. The use of a digital twin also helped in communicating clashes and staging issues with MnDOT and the contractor, Ames Construction, Muehlbach says. “The traditional way you do it is a 30%, 60%, 90% state review at each milestone,” he explains. “Here, every single week we looked at new design decisions.”

“We need to take risk out of the projects, [avoid needless] redesign. it’s all about this shared mission.”

Carlos Braceras, Executive Director, UDOT

A 4D visualization let WSB model lane closures and equipment staging for the contractor, while the 3D models offered a straightforward way to identify clashes with existing utilities and communicate the needed relocations to the utilities companies. Muehlbach says the model was viewable through a simple web-based viewer, allowing MnDOT and other stakeholders to quickly review changes to the design. And it wasn’t done just so WSB could show off for MnDOT, he adds. “This delivery method wasn’t just [for] our numbers—it was helping the contractor validate how much MnDOT was saving.”

Design work on the TH 169 interchange project is complete, and construction is set to begin in April. WSB has already decided to use its 3D-first approach on another project for MnDOT, a rail underpass in Moorhead, Minn., says Muehlbach.

Software from vendors such as Aurigo (above) or Bentley Systems (below) can offer advantages for design and execution of projects, but agencies need to be prepared to maximize the benefits of digital project delivery.

Image above courtesy Aurigo Software, below courtesy New York State DOT

*Click on the images for greater detail

Solving the Broader Problem

While there are bright spots, obstacles still remain for wider technology adoption in public infrastructure. At many DOTs, it’s not a matter of willingness to try new things, but finding the resources necessary to make the leap, says Mike Tooley, former head of Montana DOT and currently senior director of industry strategy at Aurigo Software, a provider of cloud-based capital project management tools. “Back when I first came on at Montana DOT, I was confronted with a wall of paper,” he recalls. “Everyone agreed the paper-based [system] was bad, but there was this perceived lack of resources—a failure to invest in our own technology infrastructure.”

“Everyone agreed the paper-based [system] was bad, but there was this perceived lack of resources.”

Mike Tooley, Former Director, Montana DOT

Tooley notes the potential impact of technology investment in the context of the IIJA. “Vendors typically need one-quarter of one percent of your program to institute a system. That’s 5% or more in savings. If you take 5% savings in efficiency against $1.2 trillion, that’s $60 billion.”

MnDOT is trying to lean in a similar direction toward digitization ahead of the IIJA push, MnDOT’s Hruby says. “We have three basic needs for digital models. First, the ability to sign and seal that model. With that comes the requirement that engineers can validate the model. The second element is contract provisions and language to support use of that model within our process. Third—we need to cultivate the comfort level of both contractors and our inspection staff.” MnDOT is “actively working to solve those three elements,” Hruby adds.

And it’s not just a matter of finding the right technology partner and hoping for the best. There are other considerations, including ensuring that smaller contractors are still able to bid effectively, says Hruby. “One of our problems is that as we partner with the broader world of contractors, they don’t all invest in technology unless it is broadly used,” he says. This can lead to some contractors feeling left behind, and agencies need to ensure any technology adoption comes with outreach to the contracting community to ensure bidding is competitive. “We need to carry all of our partners forward,” he adds.

And for larger contractors that have already made technology investments, getting public agencies to use up-to-date technology has its own challenges. Granite Construction, which serves many transportation clients including working within UDOT’s digital delivery program, is always looking to offer its expertise, says Aaron McClellan, Granite’s construction technology manager. “We always try to help clients see value from the construction stance to incorporate technology that provides value to them.” And he sees the IIJA as a sign things may be changing. “A lot’s going on, especially with the approval of the bill that’s going to allow more funding in a short timeframe. Adoption of technology will help [these public clients] keep up with ebb and flow of being able to deliver these projects.”

While the public construction sector has lagged in adopting these technologies, the rest of the industry hasn’t been standing still. “These technologies have been around for a quite a while, a decade and a half—BIM, re-proceduring delivery around 3D, richer artifacts in documents—we’ve been at that capability there for a long time,” says Dustin Parkman, vice president of mobility at Bentley Systems. “What hasn’t happened is use of these technologies across the entire portfolios [public agencies] manage.”

“we can’t challenge problems with the same old methods… Technology will

naturally fill that void in creative Ways.”

Dustin Parkman, Vice President of Mobility, Bentley Systems

But a combination of the funding in the IIJA and the pressing need to replace and upgrade existing infrastructure in the U.S. may be a “perfect storm” for technology adoption, he adds. “All of this creates opportunity to think differently than in the past—we can’t challenge problems with same old methods, we can’t just scale up with more skilled labor,” notes Parkman. “So technology will naturally fill that void in a lot of creative different ways … there’s [going to be] a tremendous amount of innovation in the next few years.”

Thinking along the same lines, Si Katara, co-founder and president of technology firm HeadLight—which offers cloud-based documentation tools for transportation projects—says construction and technology are “at a moment where it’s all hands on deck.” The IIJA, with its $150 billion in discretionary funds, will enable public agencies to “adopt innovations, processes and technologies to deliver bigger pieces of what’s required over the next five years,” Katara says. “The conversation [with public clients now] is ‘yes, there is a 30% to 50% increase in funding.’ They’re looking at how they did business for 30 years and they don’t have the human resources. How will they bridge the gap? By focusing on applying innovation.”

“We should all have a sense of urgency to constantly push ourselves to work better,” says UDOT’s Braceras. “People talk about wanting stability, getting back to normal—we’re never at a normal. We’re always evolving through a process of change.”

Post a comment to this article

Report Abusive Comment