They will slip into the tunnels each night on a custom-made work train, prepared to raise track, pour concrete and manhandle 3-ton steel plates as part of a $313-million project to seismically retrofit the Transbay Tube under San Francisco Bay. Then, in early morning, construction crews will ride the train out again, leaving no trace of their work behind, so 70,000 subway commuters can travel undisturbed between Oakland and San Francisco.

Scheduled for completion in 2023, the six-year project includes installation of a curved, inner-steel lining on key sections of the 3.6-mile-long tube as well as an upgraded water pumping system. The tube retrofit is part of Bay Area Rapid Transit’s Earthquake Safety Program, which includes $1.2 billion of seismic improvements to the BART system, originally completed in 1972.

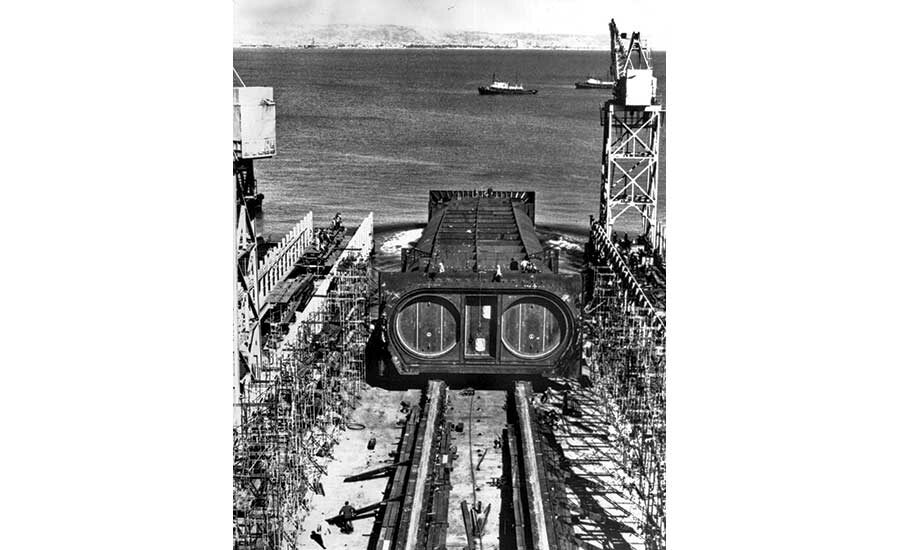

The tube itself was sunk into a trench at the bottom of San Francisco Bay in 1969. The steel and reinforced-concrete structure lies buried in sediment between two of California’s most treacherous earthquake faults: the Hayward fault three miles to the east and the San Andreas Fault, less than a mile away. The tube’s cross-section resembles a pair of binoculars, with two 70-ft-dia tunnel “bores” that carry the subway trains. The bores are divided by 8-ft-wide spaces known as galleries, used as exhaust chambers and access areas.

“This tube is ground zero for both faults,” says Tracy Johnson, BART’s chief development and construction officer.

BART operates 121 miles of subway track that links San Francisco and Oakland with the rest of the Bay Area. While the tube is structurally sound, a 1,000-year seismic event could cause the structure, lying an average of 80 ft underwater, to crack and leak. The retrofit is designed to handle a “maximum credible earthquake,” a 7.1-magnitude quake on the Hayward Fault or an 8.0-magnitude quake on the San Andreas Fault.

Construction is being led by a joint venture of California Engineering Contractors Inc. and Shimmick Construction, acquired since the start of the project by AECOM. Crews began in 2017 with steel plating in the galleries and preparations for work in the bores. The project’s work train will begin running in May to support crews’ installation of steel plates in the tunnels.

Composed of 57 sections averaging 330 ft long, the tube is 48 ft wide and 24 ft high and made of reinforced concrete with an outside steel liner, says Zach Amare, BART’s group manager with the Earthquake Safety Program. Seismic joints at each end allow the tube “six degrees of freedom” to move in multiple directions in the event of a quake.

BART retrofitted the 1960s-designed joints in 2009, adding a “big steel Band-Aid” to protect the tube against a potential underwater landslide, Johnson says. “Each joint is the most beautiful engineering design. It’s so innovative, so simple and effective—and all done on a slide rule.”

Plans for a seismic retrofit of the tube began with vulnerability studies soon after the 1989 Loma Prieta earthquake, Johnson says. While the BART system recovered quickly from the 6.9-magnitude temblor, resuming partial service almost immediately and full service within 48 hours, studies focused in particular on the Transbay Tube.

Experts worried initially that in the event of a major earthquake, the soil around the tube would liquefy, causing it to float. But geotechnical analysis verified by seismic testing of models in the University of California at Davis centrifuge facility showed that effects of liquefaction would be minor, and ballast boxes originally welded to the tube would prevent uplift.

Instead, experts discovered that landslides caused by large quakes could move the tube, straining and possibly cracking the outer steel shell and causing leaks.

“The tube was modeled using finite model analysis to see how this long snake is going to move during a massive earthquake,” Johnson says.

The analysis found that in such an event, welds in the steel liner could leak in strategic places—generally where surrounding soil conditions change, such as from solid ground to bay mud. Since the outer steel shell is primarily a water barrier, not a principal structural component, it’s vulnerable to leakage, not structural collapse, Johnson says.

BART officials originally explored external solutions to address the vulnerabilities, such as adding a rubberized membrane to the exterior or improving the ground the tube sits on, says Roupen Donikian, project manager with the tube’s original designer, Parsons Brinckerhoff, now part of WSP. Such membranes are typically applied to the exterior of an underwater structure, but crews could not access the buried surface of the tube, and the membranes don’t meet BART’s standards when applied to the interior.

“With these extended structures, ground motions are variable from one end to another,” Donikian says.

So the project team elected to waterproof the tube internally against a 1,000-year seismic event, Amare says. Workers are adding steel plates in 15 of the tube’s 57 sections, with rubber membranes installed beneath the train tracks.

The project will use 10,000 tons of steel plating. Mechanical arms will lift the plates off the work train and maneuver sections of curved steel plates to form archways inside the tube. Then crews will weld the plates together and bolt them into place, using grout to adhere steel plates to the concrete walls.

All the sections of steel liner are being prefabricated in China, Amare says. “One of the project’s challenges is making the plates to the exact correct configuration and installing them so they all fit together precisely and correctly without rework.”

The Night Shift

To install waterproof membranes beneath the tracks, crews raise a section of track each night and replace its concrete bed, inserting a layer of plastic between the old and new concrete. This technique eliminates the need to cut the steel rails, so trains can begin running again at 5 a.m.

The project team is also installing new pumping systems to replace the current system, which can remove 1,000 gallons per minute (gpm) in each direction of the tube. The new system can remove water at about 4,000 gpm on the west side and 2,600 gpm in the opposite direction.

Allowing BART to continue normal operations during the retrofit is the project’s biggest challenge, Amare says. Workers will install liners in small sections during a 6.5-hour work shift every night, setting up and clearing away all equipment and materials.

During the workweek, crews will enter the tunnels at 9 p.m. on the 800-ft customized work train. Composed of three diesel locomotives and 14 flatcars (each one configured for a specific task), the train will transport steel plates and concrete material, Amare says.

BART officials also decided to open passenger service through the tube an hour later, extending the available work window by at least 20%, saving at least $15 million and shortening the project timeline by nearly four months.

“There will be about 100 workers down there, installing these plates in the bores where the trains run every night. They’ll slip in and out under the cover of darkness,” Johnson says.

Post a comment to this article

Report Abusive Comment