Three tidal turbine energy developers, including one U.K. company, are planning to test their prototypes at the world’s first-of-its-kind permanent tidal test site on the Cape Cod Canal in Massachusetts.

“The Bourne Tidal Test Site is the only place in the world where turbines can be tested in the stable and repeatable conditions of a test stand in real ocean conditions,” says John Miller, executive director of the Marine Renewable Energy Collaborative, which oversaw construction of the test platform in the canal’s strong, predictable currents.

“We’re targeting developers with devices that need to be tested before going to full scale,” Miller says. “Currently, developers have to develop to scale and build their own test site.” That can require a lengthy and cost-prohibitive permitting and testing process, he says.

The site is expected to help tidal energy developers with early stage projects. “Barriers to entry in this business are very big in dollars and knowledge,” says Chris Sauer, president of Ocean Renewable Power Co., which is developing commercial-scale ocean and river tidal technology.

“In the U.S., with the low cost of natural gas and electricity, we won’t be able to compete with natural gas for 15 to 20 years,” Sauer says. “We’ve made progress, but a lot of other companies have fallen by the wayside … unable to attract investment or afford to build their own test sites. It’s a long, hard process.”

The collaborative is working with researchers from the University of Rhode Island to collect data using two Acoustic Doppler Current Profilers to analyze water flow in order to determine the optimum position for the test stand, Miller says.

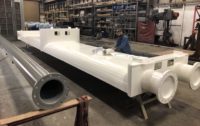

The Bourne test platform, located 100 ft from shore under a railroad bridge, includes a structure on which turbines up to 50 kW in capacity and 3 meters in dia can be tested.

Designed like a “mini, mini oil rig,” the structure rises 20 ft from the surface of the water to the top of the platform and is 25 ft wide, says Carl Horstmann, president of MassTank, which manufactured the platform and support structure.

The roughly $300,000 project, funded by the Seaport Economic Council in Massachusetts, involved building a test stand in 7-m-deep waters that flow 2 m per second on a tidal basis—the minimum velocity needed for deploying in-stream tidal devices in an economically viable way, Miller says.

Eben Franks, who replaced Miller as the test platform project manager in April, says the pre-permitted site will accelerate the development of new technologies.

The three developers, whom Miller was not at liberty to identify, plan to test technologies that include a classical axial turbine with shroud, a cross-float turbine and an oscillating blade that moves up and down like a whale’s tale.

In addition, four U.S. developers—including firms from Massachusetts, Michigan and Tennessee—competing in an ongoing Dept. of Energy funding opportunity have stated in their proposals that they plan to test their devices at the Bourne test site, Miller says.

The platform was originally bid with a fixed mount for turbines and only two piles, but the GZA GeoEnvironmental design team suggested adding an arm to allow turbines to be raised for servicing, Miller says. “This provided so much additional value to developers that MassTank’s scope was adjusted and we reprogrammed funds to allow for the change,” he says.

During the eight-day installation in November, “AGM was doing incredible work driving the 90-foot piles 45 feet into the seabed with enough precision to allow the platform mounting rings to fit perfectly,” Miller says.

John Mikutowicz, president of AGM Marine, says that while installing three piles using a Triton three-spud barge, they hit a boulder and had to relocate one pile about 6 ft, delaying the project by two days and driving it into the red.

“Everyone on the team was committed to the project, and MassTank went the extra mile in doing the work at cost,” Miller says. “The Commonwealth ended up with a great asset for this new industry at a very low cost.”

Post a comment to this article

Report Abusive Comment