As the construction industry explores the use of small-scale 3D printing for small components, others are thinking bigger.

The Dubai Future Foundation recently announced the completion of a set of small, single-story office buildings constructed from 3D-printed structural elements. The building’s components were 3D-printed in China over 17 days, then shipped to Dubai and assembled on site. The pod-shaped buildings were assembled on site from custom-printed components from a 3D printing facility in China. But the 2,690-sq-ft demonstration project is only the beginning of the process, according to the designers.

“It was very exciting to be working with a new technology that we didn’t have any experience with,” says Tod Desmarais, principal at Gensler. “To do a whole building with 3D printing—there was no previous information to go by or research or studies for something on this scale—we had to develop everything afresh.”

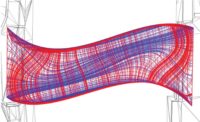

The design team consisted of Gensler as architect and Thornton Tomasetti as engineer, with Syska Hennessy serving as MEP consultant. The single-story structures were assembled from 3D-printed pieces, two halves per pod. Fabrication was done by China-based WinSun, which has a 3D printer capable of printing in an envelope up to 120 ft by 40 ft by 20 ft. The printed components for this project were limited not just by the printer’s capacity but by the dimensions of shipping containers, so the components could be transported easily from China to Dubai.

According to Desmarais, the WinSun printer uses a “cement-like” ink material to build up the components, layer by layer. “The material is unusual. Normally, in 3D printing, you’re using some kind of metal or fiberglass, but this is a kind of concrete. Using this concrete gave us the option to do structural floors and walls,” he says.

“During the fabrication process, the printer would print like a tube of toothpaste, going around and around,” says Greg Jasmin, Syska Hennessy principal. The additive 3D printer followed the Revit files exported by the design team, and its tolerances and level of detail were a function of the amount of time available for printing. “It does have the capability to be fairly precise in its tolerances. But when you print with extra precision, it’s like just printing on a piece of paper: If you have a really fine dot pattern, like 500 dpi, it might take a minute or two to print a page, but just printing text can be done in seconds,” says Desmarais.

The Dubai offices are the first large-scale project ever done by WinSun and, in fact, are the first-ever large components to come out of its printer. “Generally, you’d want to run a few test modules, but there wasn’t any time for that. We just built the building we designed, they printed it, and that's it,” says Desmarais.

Given that there is no going back once "print" button is pressed, the team had to find a way to work with the largely untested material. “We tried to figure out as much as possible during the design process,” says Jasmin. “How to heat and cool it? With prefab, you have the piece, and you need to work with it. But with 3D printing, if we needed space for a conduit, we could change the Revit model. So, when you’re printing, it’s accounting for that cavity.”

“We did do some small testing of the material—the basic ink component— and were able to ascertain what its structural quality would be when printed,” says Desmarais. While there are no plans yet to use the WinSun-printed components for multistory buildings, Desmarais says the material has performed better than expected.

The road to this demonstration project took some time. In 2014, Gensler was approached by WinSun Global, a joint venture of China-based WinSun and foreign investors seeking opportunities to use its 3D printing process in construction. Initially, the plan was to 3D-print residential structures that could be quickly deployed and assembled when needed, such as in the aftermath of a natural disaster. Gensler and the rest of the team had five prototype 3D-printed residential structures designed when, in June 2015, WinSun saw an opportunity to partner with the Dubai Future Foundation. “Our clients decided they wanted to use this process right away, so we switched from residential, using the same planning for the housing to create offices,” says Desmarais.

The greatest hurdle for the project came in meeting building codes and fitting the structure to the site, according to Jasmin. Dubai did not have building codes in place for 3D-printed structures, and the team had to work with municipal officials to ensure compliance. “No one has done this before,” he notes. “So, what is the earthquake zone [and all these] other concerns—all of these structural tests had to be done in the U.K. or Shanghai. This technology is still in its infancy.”

Jasmin cites a close working relationship with the Dubai building authorities during the predesign process as a major reason the project was able to proceed. “We had pre-meetings with them before and during construction. Without that link, how do you get the sign off from them? How is it compliant? We don’t have the standard construction documents to give them,” Jasmin observes.

The main advantages of the 3D-printing process are the rapid fabrication and the savings on labor costs, says Jasmin. According to the Dubai Future Foundation, the office project cost approximately $140,000 to build, with a 70% savings on labor costs.

But while the technology has room to grow, Jasmin expects it to grow fast. “The possibilities for the technology are wide open, and the industry will dictate where they take this. But you can be sure this will disrupt the construction process and the industry if this type of process is widely used,” Jasmin says.