The Construction Industry Institute research team studying the difference between "commodity" and "value-added services" from contractors found some surprises in the results. Contract awards based on price, contractor history with the owner and compatibility of software used did not build "value" into a project. The team created a "Net Value-Add Assessment Tool" to help owners to evaluate contractor capabilities in relation to project value.

The results of this and other industry studies were released at the CII annual members meeting in Grapevine, Texas, July 19-21. The research will be presented again at CIIs public Construction Project Improvement Conference at the University of Texas in Austin Sept. 11-13.

| Pre-Qualification Stage | Positive Correlation to Net Value-Add | Negative Correlation to Net Value-Add |

| Bonding capacity | Strong design management capability and resources | |

| Means of demonstrating delivery track record over recent projects | Contractor history with owner, including number of prior projects | |

| Management of contractual risk | Management information system | |

| Construction management systems | Managerial experience | |

| Contracting teams resumes for key personnel | Compatibility of software used | |

| Final Bid Stage | Contractor executive support with owner | Office locations |

| Formal problem resolution procedure | Strong design management capability and resources | |

| Demonstrated means of integrating planning process with scheduling software | Compatibility of software used | |

| Means of demonstrating delivery track record over recent projects | Parent company ownership, and support | |

| Innovative contracting strategy | Contract price | |

| Unique field delivery strategy | SOURCE: Construction Industry Institute Research Team 205 | |

| Actual field verification procedures |

| |

| Constructability (capability, experience) | ||

| Contractor commitment to zero injury goal | ||

| Safety plan (definitive, relevant, accountability) | ||

| Safety personnel experience | ||

| Use of sustainable development tools and philosophies | ||

| Reducing ongoing facility operating costs | ||

| Contract financial penalties | ||

"At our first meeting, we had the contractors on one side of the room and the owners on the other," said Stan Schaffer, co-chair of the study team and engineering manager at Anheuser-Busch Co., St. Louis. "We started at opposite ends, but we ended up working well together." The team found so much miscommunication between owners and contractors that they named their session for the movie Lost in Translation. The important first step was to develop precise definitions of terms.

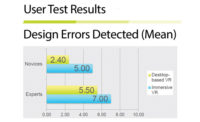

The team studied 71 projects submitted by 34 owner-contractor pairs. Project size ranged from $250,000 to $1 billion, with the average project size at $100 million. It ranked 80 differentiators and asked 91 general project questions. The projects represented all contract types.

In analyzing the project data, the team looked at the percent change in benefits and subtracted the percent change in costs, which was defined as the net value-added. Of the 12 categories of differentiators, seven had a positive relationship with net value added, but contrary to owner perception, contract price was not one of them. Robert McManus, manager at the Southern Co., Atlanta, said, "The lesson was that owners who emphasize price too much," are not getting the most for their money.

Another surprise was that a contractors recordable incident rate did not have a positive correlation. It was the presence of a definitive safety plan that made a

difference. Similarly, while compatibility of software used did not correlate positively, the more specific feature of integrating planning processes with scheduling software produced a positive correlation.

Part of the equation is missed opportunities. The owner who puts too much emphasis on prior relationships with contractors may eliminate consideration of other contractors who have value added benefits. "You can take intuition too far," said one team member.

CII Chairman Dennis Schroeder, president of BE&K Engineering Co., Birmingham, Ala., announced the institutes research agenda for 2006. Topics include the application of lean construction techniques, craft training, lawyerization and safety. CII research is free to members and for purchase to nonmembers on www.construction-institute.org.

| Related Links: |

| Behind the Scenes at the Construction Industry Institute, July 26, 2005 |

Post a comment to this article

Report Abusive Comment