|

| Kashiwagi |

“The [common] construction industry model is all wrong because you need to buy construction as a best value, not as a commodity. When that happens, skill levels will again become important and quality will improve,” says Dean T. Kashiwagi, director of the Performance Based Studies Research Group at ASU’s Del E. Webb School of Construction. “We need to change behavior in order to get a better product. If we minimize the information flow, people will become accountable. And where you have a lot of management, it means inefficiency because technical competency minimizes management.”

PBSRG studied time, budget and satisfaction complaints associated primarily with design-bid-build project delivery and the persistence of nonperformance problems even when partnering, continuous improvement and long-term alliances were involved. It determined that many owners still operate in a price-based commodity environment driven by minimum requirements, which drives high-risk, adversarial relationships and the need for more management.

Owners have a choice of directing projects through a management process or outsourcing leadership to a high-performance contractor, says Kashiwagi. “Outsourcing is much more efficient because contractors manage themselves and only highly skilled personnel can do the work,” he says. “Anyone can work under a management control model, but it makes the environment noncompetitive because performance is guaranteed at the lowest level, which maximizes the client’s risk.”

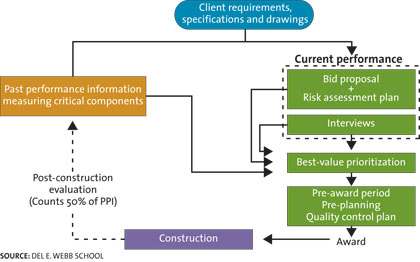

In response, ASU researchers developed the Performance Information Procurement System (PIPS) for contractor selection. It tested the system on $300 million of construction with a variety of owners. ASU reports 98% on-time delivery, no change orders and an 80% reduction in management functions.

Under the system, PBSRG acts as a consultant to the owner and the owner makes a donation to ASU ranging from $10,000 to over $100,000, depending on the project size and needs. That is used to pay ASU overhead and Del E. Webb School faculty and students who work at PBSRG. So far, the PIPS program has raised over $5 million, says Kashiwagi.

|

|

PIPS seeks best value through modeling that forces contractors to use their “A” team. It identifies the best in contractors’ past performances, assigns self-motivated project leaders, fosters competition based on performance and price, has a pre-award phase and measures project performance, the researchers say.

Interested contractors submit a spreadsheet of their best past performance to PBSRG, which enters it into a master matrix. The contractors then are given the new client’s requirements and are asked to submit a bid and develop a detailed project-risk assessment plan.

|

PBSRG interviews key project personnel to determine how they will add value and enters that information into a “displaced-ideal” decision-making model and a linear matrix. PBSRG then rates contractors by best value.

In a pre-award process, the leading contractor creates a quality-control plan that also identifies and minimizes risk. Based on PBSRG’s recommendation, the owner then awards a guaranteed-maximum-price or fixed-price contract, making performance the critical component.

During construction, the owner manages the contractor through a weekly report that identifies upcoming risks. Upon project completion, the contractor is rated on its ability to control costs and schedule and meet the owner’s expectations.

|

| Savicky |

“There isn’t anything revolutionary about the decision-making model itself. The revolution is in how we apply the best-value concept,” says John Savicky, PBSRG project manager. “And the critical element is how we collect and use the information.”

Many owners use PBSRG and PIPS for multiple projects. “We run it the first couple of times and then try to turn it over to the owner’s team,” says Kashiwagi. “If successful, we run data support until we can turn it all over.”

|

| Roof projects for United Airlines met highly specialized needs. (Photo courtesy of PBSRG) |

Participating owners include Intel, Boeing, United Airlines, state of Utah and the Federal Aviation Administration. United appears to be a satisfied customer. “We did about $13-million worth of roofing, painting, floor-coating and elevator projects over a two-year period. The process was a lot quicker with zero contractor-generated change orders and 98% were finished on time and all within budget,” says Ron Campbell, former United staff specialist. “The big thing is change orders. The PBSRG process works.”

According to Campbell, United wanted the best roof with the longest warranty. “We maintain equipment on them every day, which results in a lot of foot traffic. So four different winning contractors had to design 10 different roofs to meet our needs. They did so and we still had budget money left over,” he says.

ASU ran the proposals and models, which coded but did not identify the contractors. “The nice thing about this is you don’t know the contractors and the bid, you only select the proposal that best fits your needs,” says Campbell. “Once you pick a winner, you get the price. If it fits the budget, it’s a go.”

|

| Koebergen |

The city of Peoria, Ariz., a fast-growing suburb of Phoenix, has completed one PBSRG project—a $1-million public park—and has 14 more totaling about $112 million in the works. “We were looking for more efficiency in our selection process. Before 2000, we only used low bid and had some problems meeting schedule and maintaining budget,” says Herman F. Koebergen, Peoria materials manager.

The 14 projects now under way include a water reclamation plant, library, fire stations, parkway and performing arts center. “Everything indicates that they will all be as successful as the park,” he says.

PIPS was developed primarily for low-bid scenarios but also has been used to select best-value design-build teams and construction managers. “PIPS always creates an environment where the higher skilled firms have a competitive advantage, the exact opposite of price-based bidding. And it works the same way with any delivery system because its not the delivery systems that cause the problems, it’s the people who are picked,” says Kashiwagi. “PIPS forces measurement and preplanning, which in turn demands trained people to better manage the risk. That is the meaning of best value.”

fter 12 years of analyzing contractual relationships, researchers at Arizona State University have developed and refined a best-value, performance-based procurement system that improves price-driven construction. The key to the system is viewing construction as a highly skilled, technical process and that minimizing management makes it more efficient.

Post a comment to this article

Report Abusive Comment