Who, what, when, where, why and how. Journalism’s Five Ws+H have become a major assignment for builders of a $425-million homage to the Fourth Estate in Washington, D.C. The content of the interactive museum, which has the media as its message, is meant to be “devoured” by “readers” section by section. But the form doesn’t only evoke a large-format newspaper. The glass press box on “Main Street USA” also is designed to resemble a television, a camera or a world stage. The architecture is so layered with symbolism that it is taking 24 structural systems and 11 exterior wall systems—with 12 types of glass—to support or display the various double, triple and quadruple entendres. That and the prime-time Pennsylvania Avenue site put the 550,000-sq-ft job’s builders, marching toward a July 1 finish, on parade.

©Sam Kittner/kittner.com |

“It was hairy from time to time,” says James S. Polshek, of the job’s New York City-based architect, Polshek Partnership LLP. “But we beat our way through the bulrushes,” he adds.

Polshek Partnership Architects Newseum intended to evoke a television, camera, newspaper and stage.

|

For the museum team, the answers to the Five Ws were an easy starting point. “Who” is the owner, the Arlington, Va.-based nonprofit called the Freedom Forum (FF), which is devoted to the First Amendment. “What” is the Newseum, which currently is in more humble circumstances in Arlington. “Where” is the last developable site on Pennsylvania Avenue, next to the Canadian Embassy; across from the National Gallery; and midway between the White House and the Capitol, which is in plain view. “Why” is the FF’s mission to promote free press, free speech and free spirit. “When” is next fall, when the Newseum’s doors open to society.

“How” was the head-scratcher—how to form the icon, with its many angles, layers and special effects. And the generous use of structure as architecture didn’t make things any easier. “It is a very involved building, with lots of interfaces,” says Daniel A. Sesil, partner-in-charge for Leslie E. Robertson Associates. New York City-based LERA is structural engineer for the building and the exhibits.

The job’s high profile didn’t help. “I had to get approval from 21 groups, including the Secret Service and the capital police, to shut down three lanes of Pennsylvania Avenue so we could assemble or move” the crawler crane, says Mac McIntire, project executive in the mid-Atlantic office of Turner Construction Co., Washington, D.C. Turner is construction manager-general contractor for the $238-million building, including interiors. “It took a whole morning to move the crane a few feet,” he adds.

Crane operations also had to be shut down at least 10 times for parades and protests and presidential motorcades. And in deference to nearby residences, crews cannot not start hammering until 7 a.m., instead of 6 a.m., or go later than 7 p.m.

Meetings with officials to work out deliveries of the prefabricated steel truss sections, trucked in from Canada, began eight months in advance. With the biggest piece 130 ft long and 16 ft deep, “the trucks were overweight, overwidth, and overlength,” says McIntire.

Adding more stress, the project hit the street during a building boom. “Nailing down costs is impossible even to this day,” says Polshek, who also is concerned about the quality of finishes because the labor pool is stretched so thin. “How many times can you reject shop drawings?” he asks.

Despite the restrictions, the building now is 70% complete and on time and on budget, reports the owner.

LERA News van exhibit was installed early

|

The 250,000-sq-ft interactive museum is designed to accommodate 1,500 visitors per hour. But there is more to the complex. Housing was a city requirement for the site, which the Newseum bought from the District of Columbia for $100 million—$25 million of which will be used for low-income housing elsewhere in town. In addition to 140,000 sq ft of condominiums, there is administrative space and below-grade parking. The museum will contain a 500-seat theater, two broadcast studios and 34,000 sq ft for exhibits designed by Ralph Appelbaum Associates, New York City. Exhibits include a memorial to journalists killed on assignment—their names will be etched in glass, a Berlin Wall guard tower, a news helicopter, a news van and the top 27 ft of the World Trade Center antenna. The Freedom Forum’s endowment is footing the bill, except for $73 million—mostly from media giants.

Polshek Partnership Architects |

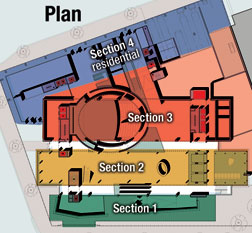

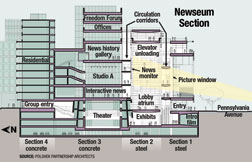

The building, which has a trapezoidal plan and steps up in height from 80 ft to 118 ft, has four main sections, largely rectilinear in shape. The first three house the Newseum and are interconnected by 11-ft-wide visitor circulation strips, steel-framed walkways and bridges covered in glass. The fourth section, framed in concrete, is the 12-story condominium. Washington is a concrete town, so the engineer used steel sparingly, mostly for long spans and open spaces.

The Newseum’s 252-ft-long and up-to 95-ft-tall “front page” is the most transparent. Passersby on the avenue will be able to watch a 50 x 32-ft news monitor, which hangs in section two, through an 80 x 60-ft picture window, supported using tensioned cables and vertical steel trusses. Interrupting the transparency is a 74-ft-tall, 52-ft-wide tablet. Etched in the stone is the beginning of the First Amendment.

| + click to enlarge |

|

Section two, though more dense, also is framed in steel except for a concrete core near the west end. The section contains a 157 x 42-ft lobby atrium with a 90-ft-high ceiling and three oversized, hydraulic elevator cabs, enclosed in glass.

Section three is framed in concrete. It contains exhibits, the theater, building services and offices.

“The building is packed with almost every conceivable structural system, in steel and concrete,” to respond to the design, the program and local market conditions, says LERA’s Sesil. The goal was to devise “intuitively simple and stand-alone systems” and minimize interdependencies “for the sake of construction,” he adds.

LERA Workers erect megatruss.

|

Four of the eight steel systems are architecturally expressed. The two most exotic are a bent column that doubles as a grand stair and a hollow, box megatruss, with expressed webs. There is an expressed Vierendeel truss, a cantilevered steel truss and two-way cantilever construction with torsional box beams.

For consistency, most expressed elements are made of steel plate assemblies, regardless of the structural system. “That meant one family of detail, one language” for the fabricator, says Sesil.

Two of the 12 concrete systems above grade are expressed. There is a post-tensioned beam column-load transfer system; a post-tensioned wall column-load transfer system; architectural concrete columns, architectural concrete beams—conventional and post-tensioned—and concrete core walls. Floor framing includes flat-plate construction; conventional beam and slab construction; one-way joist construction; post-tensioned flat-slab construction and a system of post-tensioned beams. The four-level, 45-ft-deep basement has four concrete foundation systems.

The most visually dramatic of all the structural systems is the 70-ft-tall bent column grand stair for it appears to have no visible means of support. The rationale...

Post a comment to this article

Report Abusive Comment