A new interface between a suite of design products used to create many of the world’s process and power facilities and an explosion-consequence prediction tool shortens the time needed to run safety analyses of plant designs from weeks or months to days or hours.

“The interface between Intergraph’s rules-based 3D design solution and GexCon’s FLACS explosion analysis software can help designers increase productivity and enhance safety before plant construction begins,” says Tom Fiske, a senior analyst with ARC Advisory Group, an industry analyst firm.

GexCon, a Norwegian software developer and consulting firm specializing in computational fluid dynamics, developed FLACS to analyze, based upon design, the chances and effects of explosions in facilities. It developed the tool with direction and support from 10 of the world’s largest oil and gas companies, which uses the tool to identify hazards and consequences.

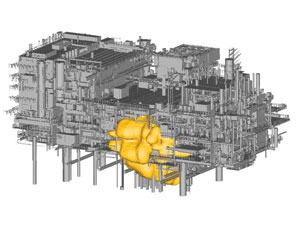

Prior to the newly announced interface with Intergraph’s SmartPlant and SmartMarine 3D design products, using FLACS required remodeling the facility from scratch, which could take months. Intergraph’s rules-based design software enforces safety early in the designing process, ensuring compliance with safety standards from the industry and its organizations. The interface will make safe designing faster and more cost efficient, the companies claim.

Post a comment to this article

Report Abusive Comment