Transportation

Contractor Covers German Highway in Hamburg to Cut Noise

Around 130,000 vehicles daily thunder along the A7 highway north of the Elbe river tunnel in Hamburg, Germany, noisily dividing the city. To eliminate this blight, contractors are building a vegetation-covered concrete box along more than 1.4 miles of highway in the busy Altona downtown district while keeping traffic flowing.

Technically, building the roughly 20-ft-tall, 138-ft-wide box "is not difficult," says Andreas Stemmer, business manager with the northeast German unit of project contractor Hochtief Infrastructure GmbH. The challenge is casting three hefty parallel walls along the highway and roofing them with 4-ft-deep slabs while keeping eight lanes open, he adds.

As Germany’s main north-south highway reaching into Scandinavia, the A7 cannot be impeded, adds Karina Fischer, spokeswoman for the federal highway authority Autobahn GmbH.

Hochtief leads a joint venture with Switzerland-based Implenia AG, which started work around two years ago on the Altona box under a $630-million contract awarded by the national highways planning and construction unit (DEGES). Because of DEGES's strict traffic management requirements, the contract is relatively long, with a late 2028 completion target, says Stemmer.

The box is one of the last major improvements of the A7 between Hamburg and the north, all of them involving Hochtief. The largest element, substantially completed five years ago, involved widening typically from four to six lanes 40 miles of the highway from the north side of the city to a junction near Bordesholm.

That work was done under a public-private partnership, including 30 years’ operation of most of the highway by a special purpose company initially owned by Hochtief, KEMNA BAU Andreae GmbH & Co. KG and investors.

The P3 contract also included the highway's first Hamburg box, covering 1,800 ft of the A7 in the residential Schnelsen district. With that work in its early stages, Hochtief in joint venture with Franki Grundbau GmbH & Co Kg started the second 3,050 ft, $235-million box a couple of miles south at the industrial/residential Stellingen area under a separate contract, completing it last year, says Stemmer.

Funded mainly by the federal government with a 25% contribution from Hamburg, the eight-lane Altona box is in one of the city’s densest areas. It starts at the junction with Behringstrasse about 1,300 ft from the Elbe tunnel’s north portal.

The completed tunnel will be covered with 3.9 ft of soil and planted. Rendering courtesy of DEGESV-KON.media

The completed tunnel will be covered with 3.9 ft of soil and planted. Rendering courtesy of DEGESV-KON.media

DEGES supplied the design, done by WTM Engineers GmbH with Ingenieurbüro GRASSL GmbH. According to Implenia, the work includes more than 38,000 yd of bored piles, 350,000 cu yd of concrete and 110,000 cu yd of earthmoving. More than 3.3 ft of soil will be spread over the roof.

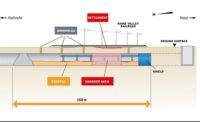

While keeping traffic flowing in existing lanes, the contractor is now focusing on completing the 3.9-ft-thick central wall by November. Traffic will then be diverted to narrow lanes on one side while the first, 3.3-ft-thick outer wall is built and 3.9-ft-deep roof slab connecting it to the center is cast. Finally, traffic will be moved into the completed tunnel half while the final wall and slab are built.

While the soft, sandy soil was always expected to be challenging, the contractor was still surprised by localized poor conditions, says Stemmer. In places, the 3.3-4.9-ft-dia piles had to be drilled to twice the 65-ft depth typical for the project, he adds. But Hochtief expects the roughly two months’ delay to be recovered, making November's deadline still achievable.