A $1.7-billion public transit line dubbed the “missing link” in Auckland, New Zealand’s rail and bus network is a step closer to construction. Two joint ventures are beginning a $2-million initial design phase for the City Rail Link (CRL), which will include 3.6 meters of tunnels.

Downer NZ, Soletanche Bachy JV, and Connectus, a joint venture of McConnell Dowell and Hawkins, will begin preliminary design for the north-south route that will cut through the heart of the city, joining the major hub of Britomart with Mount Eden. It will serve an anticipated 30,000 passengers at peak hours—double the current number—and improve intermodal connections throughout New Zealand’s most populous city, says CRL project director Chris Meale.

As the city braces itself for a 25% increase in population by 2020, the government formally committed to enter a joint business partnership with Auckland Council in 2017 and to provide funding for construction in 2020. The government has stated it is prepared to consider an earlier release of funds, provided that a number of key targets can be met, including a rise in employment figures in the central business district and increased use of public transport.

Tunnels

The 3.6 m of tunnels will include depth changes of 70 m through ground that varies between rock and soft soils. Excavation is expected to generate some 1 million cu m of spoil.

The middle alignment, between the new Aotea Station and the turnout tunnels near Mount Eden Station, will be excavated by twin 7-m-dia boring machines (TBM). They will start at Mount Eden Station and head downhill in a northerly direction to a new station at Karangahape; from there they will proceed to Aotea. In this section, the sandstone is typically weak rock, says Meale.

After construction of the first tunnel, the TBM will be reinstalled at Mount Eden for the second, parallel drive. Though driving uphill is more typical in projects using TBM, usually as a means of simplifying ground dewatering, CRL civil design manager Darryl Wong says such an option is not possible in this case. It would have required operating the machine in one of the busiest areas of the city, where mucking out and concrete segment supply would have caused massive disruption.

At either end of the route, a section of tunnel will be constructed in cut-and-cover, owing to their relatively shallow depths. As part of the Connectus joint venture with McConnell Dowell, Hawkins will construct the cut-and-cover rail tunnels under and along key transport corridors. The early contractor involvement (ECI) and design-development phase commenced in March with physical work expected to start in November.

Hawkins-owned Harker Underground Construction will be working within the Connectus team to relocate an existing stormwater pipe in the city center using specialized micro-tunneling technology. This will involve a 500-m-long, 1,950-millimeter-dia tunnel driven using the pipe-jacking method, with a precast-concrete pipe lining.

CRL construction manager Scott Elwarth expects stormwater-tunnel construction to start in November, along with cut-and-cover work.

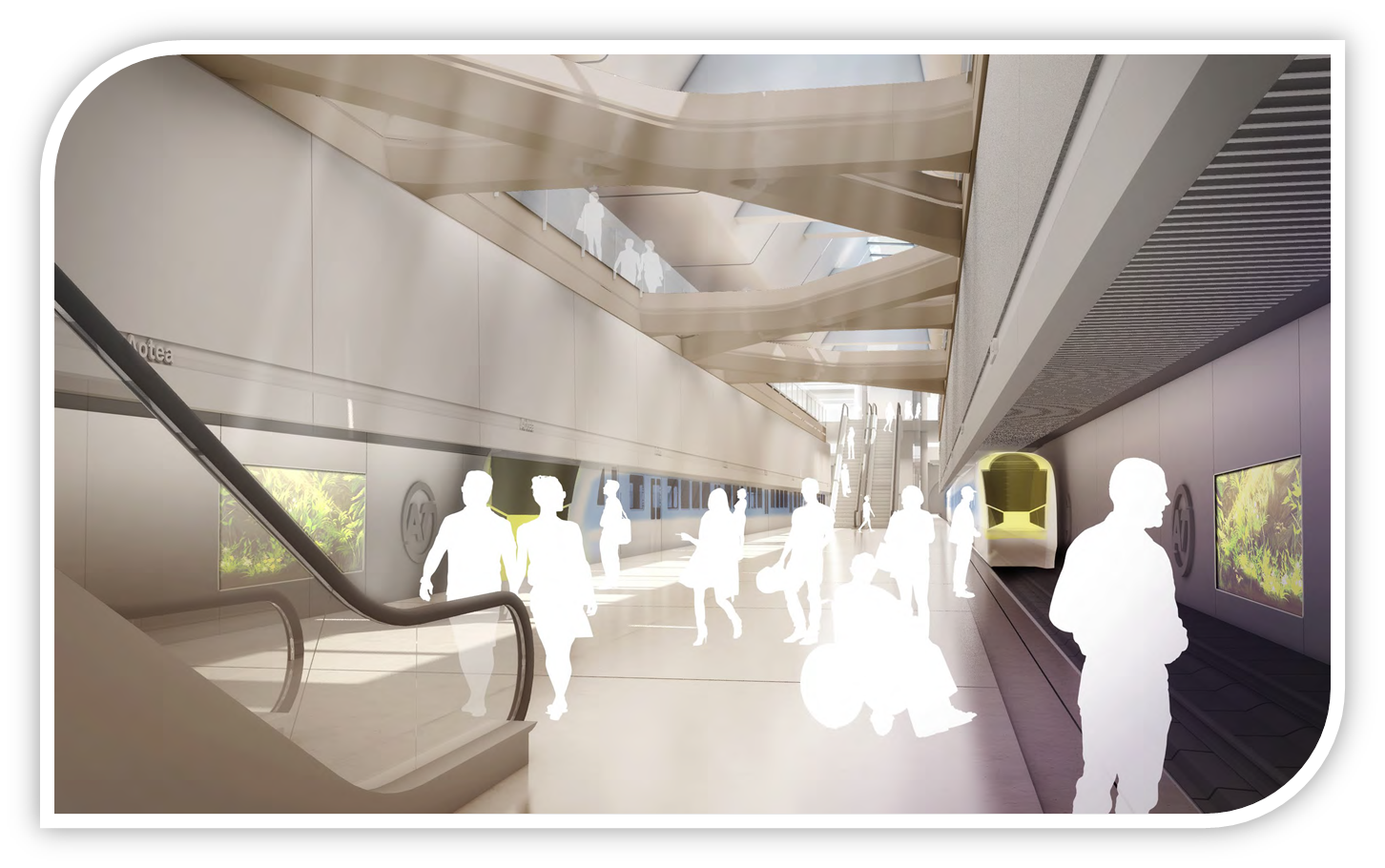

Station Construction

Cut-and-cover open box excavations will be utilized for Mount Eden and Newton stations, while a mined side-platform approach will be used for Karangahape Station. Some 11 m below ground, Britomart Station is an existing facility that will be modified to accommodate the new tracks.

According to Auckland Transport, Aotea Station could become the busiest station in Auckland, due to its proximity to cultural attractions. The station will be constructed top-down inside a retaining structure consisting of piles as deep as 20 m and shotcreted.

A delicate underpinning operation will require the Chief Post Office to close for some three years. Details have yet to emerge, but the technique is likely to involve the installation of bored piles, typically to a depth of 12-15 m, depending on geology, says Wong. “An alternative is being developed with the ECI contractor to the reference piled design solution,” he adds. “There is not a lot of experience of this form of construction in Auckland.”

Post a comment to this article

Report Abusive Comment