Federal agencies are among the nation’s largest facility owners and builders. The National Aeronautics and Space Administration, in the business of going where no one has gone before, faces challenges and must innovate every day—to explore the solar system and beyond and to build the infrastructure on earth to support its missions. Those missions range from providing launch support for commercial space ventures to landing on Mars, where the plucky rover Perseverance continues to explore.

But the series of missions currently capturing the imagination of the American public is Artemis—a program to explore more of the moon than ever before. In Greek mythology, Artemis was the twin sister of Apollo—the namesake for the mission that last put Americans on the moon 50 years ago. Notably, NASA’s Artemis program will land the first woman and the first person of color on the moon.

Related link: KSC Director Janet Petro Reflects on Diversity

Related link: Launch Sequence Software is Ready for Blast-off

NASA states as an Artemis goal collaborating with “commercial and international partners,” and two significant players among them are leading design firm Jacobs, and major design-constructor Bechtel. Lorna Kenna, vice president and general manager of Jacobs Space Operations Group, describes Artemis as a program that gives staff members the feeling that “I was part of this thing that mattered so much.” Jacobs is a solutions provider supporting NASA at eight of its 10 centers, she says, and “when we talk about Artemis, the job involves exploration, science, aeronautics—the full life cycle.” At Kennedy Space Center (KSC) on Merritt Island, Fla., the Jacobs team of 2,200 employees supports NASA’s “exploration ground systems including integration tests, checkout and processing of the Artemis missions,” she adds.

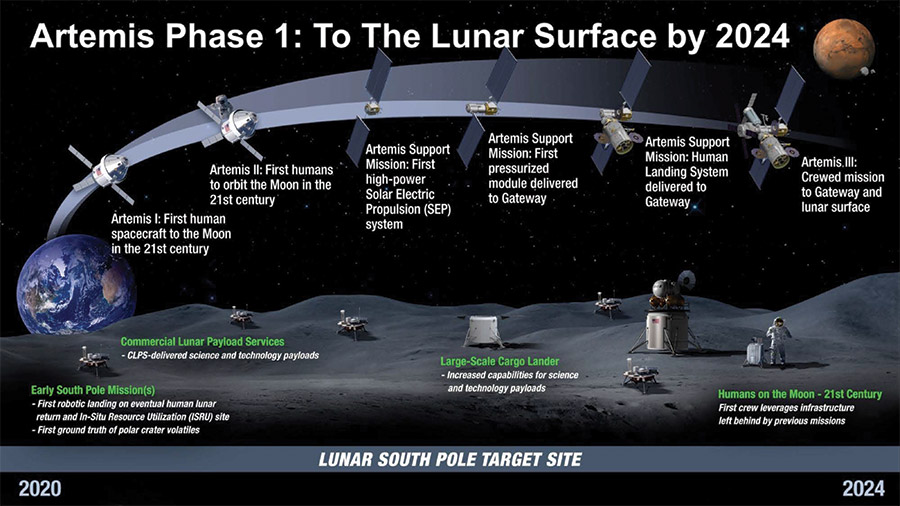

First flights (below) will test rocket systems and the new Orion spacecraft. NASA is working with industry and its International Space Station Partners to build Gateway, a lunar outpost orbiting the moon.

Graphic Courtesy of NASA

*Click on the graphic for a larger version

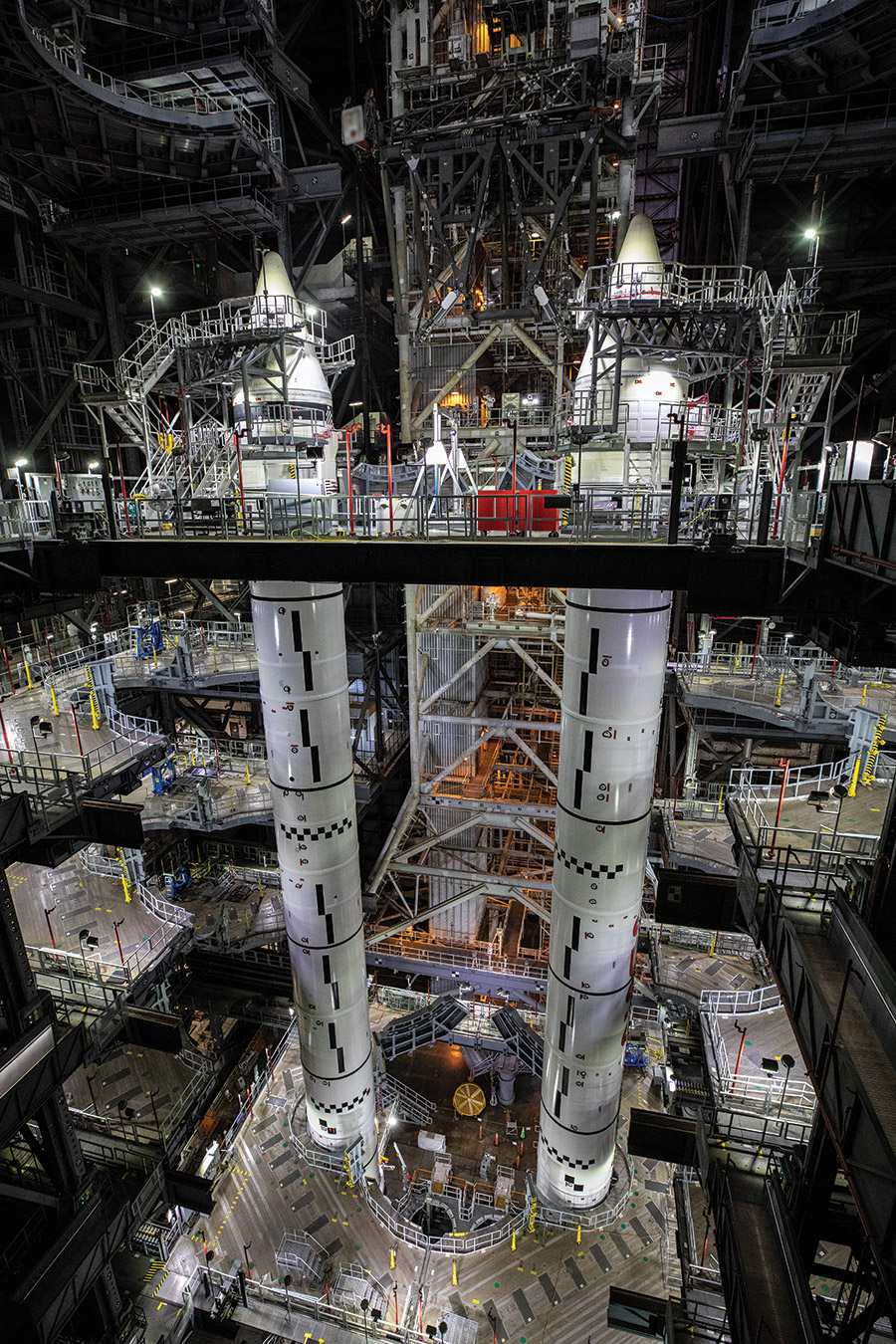

In October, the Jacobs team stacked the Orion spacecraft and launch abort system atop the Space Launch System (SLS), NASA’s new rocket, in the Vehicle Assembly Building (VAB) at the space center, marking completion of the assembly of Artemis I.

“The excitement and dedication associated with knowing that you are processing the first of a decades-long program and realizing that it is the world's most powerful rocket with 8.8 million pounds of thrust—323 ft tall as it stands structurally stacked—it’s hard to share the enormity of this,” Kenna explains.

Photo: NASA/Kim Shiflett

Photo: NASA/Glenn Benson

*Click on the photos for a larger version

NASA points to Artemis activities across the breadth of the agency without tallying a total cost, but an April status update from its Office of Inspector General projected the total through FY 2025 at $86 billion. “NASA’s development of a deep-space human exploration capability to reach the Moon as a precursor to Mars is the agency’s most ambitious and costliest ongoing activity,” it says.

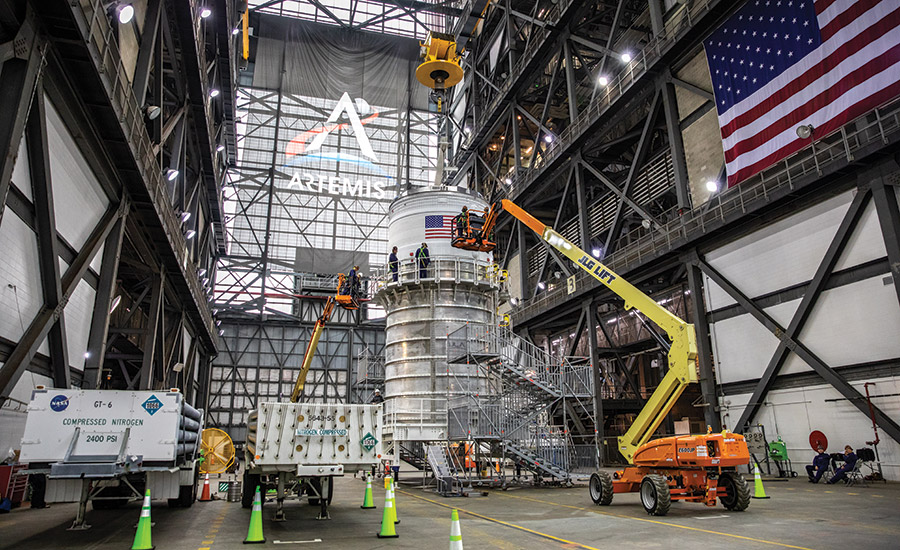

The solid rocket boosters (top right) that will help launch Artemis 1 into space are assembled by NASA and Jacobs personnel at the Vehicle Assembly Building at Kennedy Space Center. Ground operations workers (left, center) fit Space Launch Systems sections together.

Photo: NASA/Kim Shiflett

NASA’s Lunar Exploration Program Overview explains that the SLS is the first rocket with the power and capability to carry astronauts to deep space aboard a new spacecraft called Orion. The first Artemis flight will test the SLS rocket and Orion spacecraft as an integrated system, and it will orbit the moon and return (see graphic left).

The second Artemis flight will send humans to orbit the moon for the first time this century. That flight will be followed by three support missions that deliver parts of Gateway—a lunar orbital outpost NASA is developing with U.S. industry and its International Space Station partners. Gateway sections will include a solar electric propulsion system and a pressurized module.

The lightning protection towers (left) built at Pad 39B also added weather stations and cameras.

Photo: NASA/Jamie Peer

Bechtel has completed design and mobilized the construction site for NASA’s Mobile Launcher 2 for the later Artemis flights—the launch platform that will allow the agency to send astronauts and heavy cargo to the lunar surface. Michael Costas, general manager of the defense and space business line of Bechtel’s nuclear, security and defense global business unit, said his group and its subs are “right on plan to start construction in January 2022.”

The SLS and Orion programs, including the earthside construction and systems integration at Cape Canaveral, Fla., involve 3,800 suppliers and 60,000 workers nationwide, reports NASA.

To understand the work that went into transforming Kennedy Space Center’s launch complex 39B to accommodate SLS rockets that take off from mobile launchers, one has to go back to its predecessor program, Constellation. In 2006, Jose Perez-Morales, the NASA senior project manager in ground systems development and operations responsible for design, construction and fabrication at 39B, was given the enormous task of removing everything that remained of the Space Shuttle and Apollo programs.

Larger-than-ever liquid-hydrogen sphere (center) provides 1.25 million gallons of LH2 for quicker turnarounds.

Photo:NASA/Cory Huston

A Whole New Ground System

“We took out the fixed service structure and the rotating service structure for the space shuttle,” Perez-Morales says. “Every piece of electronics that was there, some going back to the time of Apollo, including about 1.3 million feet of 2-inch-thick and 3-inch-thick cables with big copper cores, they were all removed.”

All the copper wire was recycled and replaced by fiber optics, and the pad received new command and control systems. After the launch of the Ares 1-X in 2009 and the subsequent cancellation of the Constellation program in 2010, a lightning control system that consisted of three towers, each 600 ft high with a system of catenary wires designed to protect SLS rockets like Artemis 1 from lighting strikes, was installed. In the space shuttle era, lightning strikes at Cape Canaveral could short out and otherwise damage equipment on the fixed structure and the shuttles. Work on the lightning control system was completed in 2011 by contractor Ivey’s Construction of Merritt Island, Fla.

Perez-Morales said that in addition to protecting the SLS rockets, each tower has four levels of weather monitoring stations. The 12 weather stations and a system of cameras in all three towers provide 360° visibility of the SLS rocket and will help launch directors make decisions about conditions with up-to-date data at their fingertips.

Another essential addition was a 1.25-million-gallon liquid hydrogen tank at Pad 39B that will support all of the Artemis missions. It was necessary because of the quicker turnaround time needed for mobile launcher missions, and just in case private companies such as SpaceX need to launch from the pad more quickly than the further-spread-out NASA missions.

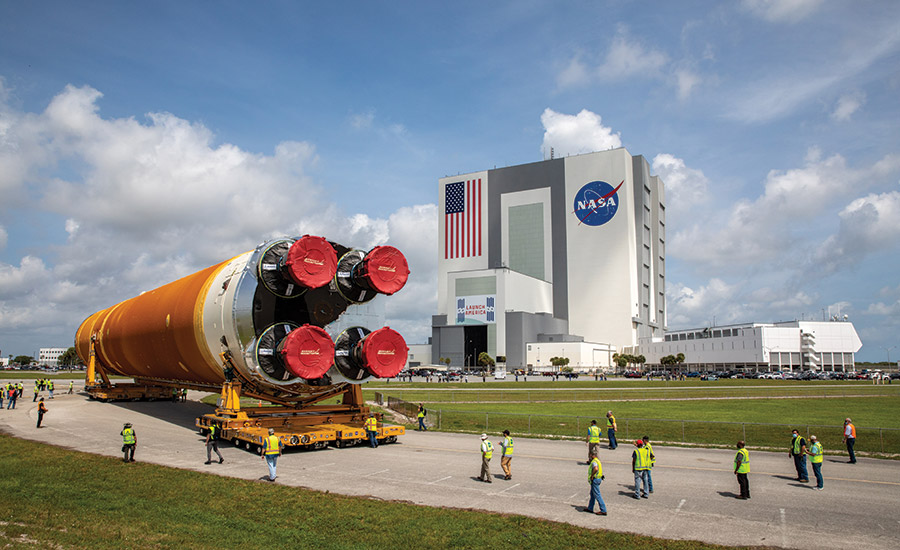

The final core stage of the Artemis 1 SLS rocket arrived at Kennedy Space Center in April and was transported to the Vehicle Assembly Building.

Photo: NASA/Kim Shiflett

“The required usable capacity for liquid hydrogen is substantially larger than the existing spheres,” says Lori Jones, project manager for NASA in the construction of facilities division. The previous hydrogen tanks used perlite to insulate the space between the inner sphere and the outer sphere. Jones says the new liquid hydrogen tank uses glass microspheres, a more efficient insulation system that came out of the spaceport’s Cryogenics Testing Laboratory. A vaporizer, flare stack, fill manifold, piping and valves into the existing liquid hydrogen system were required as well.

Perez-Morales said a new flame deflector and emergency egress system have been built to service Artemis at pad 39B. The system allows crew members to evacuate the SLS rocket via baskets that operate like gondolas.

The work at the launch pad was already underway when the mission took shape for Artemis. A presidential space policy directive in 2017 called on NASA to lead humanity’s return to the moon and beyond by 2028. A second directive in 2019 accelerated the timeline to 2024 and added the goal of landing “the first woman and the next man on the moon.” The Biden administration's then Acting NASA administrator Steve Jurczyk added the charge to land a person of color on the moon to his fiscal 2022 funding request to Congress in April.

NASA's mobile launcher 1 sits atop crawlertransporter 2 as it begins its trek to Launch Pad 39B.

Photo: NASA/Ben Smegelsky

Cognitive Shift

In a recent policy statement on diversity, equity, inclusion and accessibility, NASA Administrator Bill Nelson, sworn in May 3, added context to the thinking about diversity on the mission. “Our astronauts have taught us about the Overview Effect—a cognitive shift in awareness achieved through a transcendent perspective in space—which helps us understand that all human beings are connected by the commonality of our existence and our interdependencies on a small and fragile planet.” The policy’s definitive commitment to diversity at the agency is echoed by KSC Director Janet Petro (see here).

Both Jacobs and Bechtel leaders note that commitment and say it resonates. Costas says Bechtel drives accountability around being a diverse organization. “It does help us make high-quality decisions,” he adds. Kenna says, “Both NASA and Jacobs have embraced diversity and inclusion …. It’s an interesting fit.” Change started at the top at Jacobs and flowed down, she adds, and the “whole business followed along with that at Kennedy.”

Putting it all together in the VAB has consumed Kenna and her team for the last two years. She says they draw on their heritage of engineering to serve as a solutions provider and systems integrator. Artemis components are produced by a conglomerate of OEMs that are integrated by Jacobs. “You can do all the planning … but because this is the first ever of the world’s largest and most powerful rockets, when it finally comes together you always learn something,” she says.

The final stage of the SLS rocket was delivered after testing in April and now the team, which has persevered through the pandemic and the associated supply chain struggles, is in the final stretch of assembly before Artemis 1’s planned February launch.

The daunting requirements of the mission demand rigorous testing. Future Artemis astronauts will spend three days traveling 240,000 miles to the moon. For lunar injection return—coming back from the moon—the Orion spacecraft will have to resist more than 5,000° F as it reenters Earth’s atmosphere. Getting the complexity of systems right on the ground is paramount, Kenna says.

Jacobs’ team includes the whole gamut of engineering. Kenna says, “We also have a large contingent of software developers. One thing in addition to ground systems that we support here at KSC is development of the launch control system software” (see here).

Next Generation

Mobile launcher 1 and its crawler transport will put the Artemis 1 SLS rocket on Pad 39B for launch in February. Hensel Phelps built it for NASA a decade ago for the Constellation program. Bechtel is designing and building the replacement, ML2, which will have the peripherals, umbilical connections and a new integrated crawler transporter needed for later Artemis launches.

“After going through over 10 years of building ML1, and all of the lessons learned that came from that, we spent quite a bit of time with NASA optimizing the design on ML2,” says Bechtel’s Costas.

Bechtel reports that the cost-plus-award-fee contract for ML2 is worth roughly $402 million. Design attributes of ML2 relate to dealing with the heavier weight of SLS rockets and accommodating human factors in launchpad and flight operations—specifically how to safely protect the health and integrity of the mission and the astronauts who will fly to the moon.

The data and lessons learned from ML1 are helping optimize safety and constructability on ML2 as well. Modularization techniques and advanced work packaging adopted from the oil and gas sector are cutting design and construction time, Costas adds. Bechtel is mobilizing construction for ML2 in a parking lot adjacent to the VAB, just north of SpaceX's operations at Kennedy Space Center. The lot includes a laydown yard and a headquarters for preconstruction planning about heavy equipment and craft access to the site, he says.

The next step is building a module assembly yard—since most of the systems and structure are being delivered in sections from fab shops—and mobilizing the local supply chain using specialty contractors and suppliers with experience on projects at KSC. For example, Bechtel is working with steel fabricator JP Donovan, Rockledge, Fla., to fabricate and deliver large steel trusses that will be integrated into the base of the launch platform.

Working on Artemis projects like the SLS rocket, final pad improvements and ML2 simultaneously while coordinating with other site users like SpaceX is NASA’s new reality on earth. The agency is now a multi-user spaceport operator working with private explorers and a host of industry partners. At the same time, KSC’s Petro said in a NASA website story that the center’s future involves “the quest for … deeper exploration of the universe.” The Gateway outpost in lunar orbit will enable extensive scientific investigation on the surface of the moon and preparation for human missions to Mars.

“We’ve considered what it would take to master plan a community on the moon,” Costas says. “We recently bid some work with academia around how we help NASA plan for those missions: How do you develop the capabilities to do construction work on another planet?”

Post a comment to this article

Report Abusive Comment