The signature pedestrian bridge, built with state-of-the-art techniques, was supposed to make history and increase safety. On March 15, it did accomplish the former—at the terrible expense of the latter.

Nobody seemed overly concerned about the appearance of cracks in the structure within the five days since it had been placed—not the contractors, engineers nor the state university that was heavily publicizing its “first-of-its-kind” bridge, nor the state transportation department, whose road traveled beneath the doomed span. And the cracks were unknown to the motorists stuck waiting in traffic below.

But then the 174-ft-long, 950-ton truss structure came crashing down in seconds, killing six people waiting at a streetlight on a state road in Sweetwater, Fla., near Miami and Florida International University (FIU), which had touted its rapid placement just five days before.

In the days since, countless people—including readers of ENR—who have viewed the dash cam footage of the falling bridge have formulated their own opinions about why it happened. The possible causes and contributing factors—concrete cracking in the main span’s north end, the tightening of tendons just before the collapse, and even the design-builder’s use of the time-tested Accelerated Bridge Construction (ABC) methodology—have all been explored, if not fully examined, in word-of-mouth exchanges and website posts. Some of the industry’s leading forensic engineers are already attached to different parties involved in the project, and they, too, will weigh in. But only time will lead to the exact cause behind what happened on March 15 at 1:47 p.m.

Click image to enlarge

FIU’s $14.2-million UniversityCity pedestrian bridge project started out with lofty intentions, as the school’s design-build request for qualifications noted: “Our commitment to design excellence and design innovation is neither veneer nor luxury. This project’s success depends on an outstanding pedestrian bridge.”

Funded in large part by an $11.4-million TIGER grant, the FIU-owned project was meant to be not just a typical pedestrian overpass, but “a linear park” and a “destination in its own right where community members might linger,” FIU explained in its solicitation. The Florida Dept. of Transportation would remain on the sidelines, mostly contributing as a “pass-through” for the federal funding—a role that Gov. Rick Scott (R) suspended on March 19.

In response, the design-build team of Miami-based Munilla Construction Management (MCM) and Tallahassee-based FIGG promised an “innovative signature bridge to celebrate FIU,” according to the project proposal it submitted in September 2015.

“Once main span is erected, additional work to complete the main span construction will be performed over offpeak lane closures.”

— Contractor’s 2015 proposal

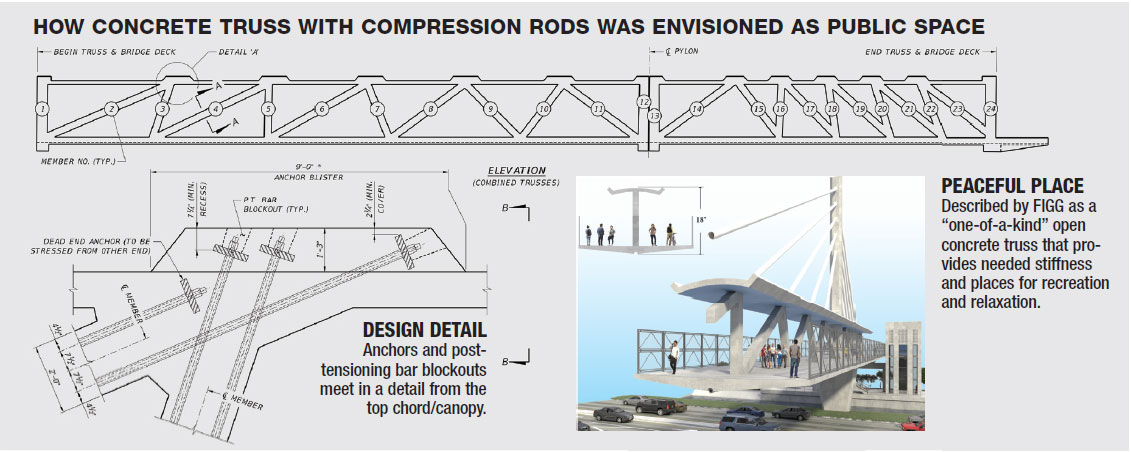

The bridge’s heart was a central, open truss, with a narrower top chord that served as a canopy over the wider bottom chord, which was to be the walking surface. Pipes that would have the appearance of cables were to have extended downward from a 109-ft-high central pylon, adding stability, but MCM-FIGG’s proposal noted that the concrete deck was to have two-way post-tensioning tendons. The concrete truss members including the canopy were to have been compressed with high-strength steel cable and bars. The bridge was to be the first in the world composed entirely of “self-cleaning” concrete with titanium dioxide.

The specific design “is not something that we’ve encountered before,” noted Robert Accetta, an investigator with the National Transportation Safety Board. “It’s not an unusual structure, but we do need to find out why and what may have caused the failure mechanism.”

Just five days before the collapse, Barnhart Crane and Rigging used self-propelled modular transporters (SPMT) to move the bridge’s 32-ft-wide, 950-ton main span—built on site—onto permanent supports, in just a few hours.

Before the collapse, FIGG’s lead engineer, Denney Pate, called an FDOT representative about cracking discovered in the structure’s north end. According to a transcript released by the agency post-collapse, Pate said that the project team had “taken a look at it” and “obviously some repairs or whatever will have to be done, but from a safety perspective we don’t see that there’s any issue there, so we’re not concerned about it from that perspective although obviously the cracking is not good and something’s going to have to be” repaired.

While NTSB and others noted that the cracking may not have contributed to the collapse, the project team had met for more than two hours to discuss the topic, FIU reported in a March 17 statement.

Meeting Convened By FIGG And MCM

At 9 a.m. on the day of the accident, “The design-build team of MCM and FIGG convened a meeting … to discuss a crack that appeared on the structure,” read the statement. “The FIGG engineer of record [Pate] delivered a technical presentation regarding the crack and concluded that there were no safety concerns and the crack did not compromise the structural integrity of the bridge.”

The structure appeared to fail at its north end. Accetta, NTSB investigator, noted March 16 that at the time of the collapse, crews were working on one of the diagonal members at the north end of the structure “applying post-tensioning force that is designed to strengthen the diagonal member.”

Among the victims was an FIU student, Alexa Duran, 18, and an employee of one of the project subcontractors, Navaro Brown, 37. The others were Rolando Fraga Hernandez, 60; Osvaldo Gonzalez, 57; Alberto Arias, 54, and Brandon Brownfield, age unknown.

Rightfully, the actions and work product of the design-build firms, the university and other project team members are facing microscopic scrutiny. But for now, nothing is known for certain.

___________________________________________________

Lawsuit Claims Post-Tensioning Triggered Bridge Failure

Before Collapse, Bridge Builders Dismissed Concerns About Cracks

NTSB Joins Probe of Fatal Florida Bridge Collapse

___________________________________________________

Early on, news outlets and others singled out the use of ABC construction methods, with several having since noted the technique’s time-tested status.

Atorod Azizinamini, founder of the Center for Accelerated Bridge Construction at FIU, had told ENR in an interview the day before the collapse that the bridge actually was a hybrid of ABC and cast-in-place construction. “ABC was only used for the section [over] traffic.”

Other possible causes are in play, notes John Hillman, an award-winning bridge engineer. “Everyone wants to blame ABC methodologies or stress testing of tendons or lack of adequate falsework,” he says, adding that the bridge’s unfinished status doesn’t mean that it was unsafe.

“It is not at all unusual to have components of a bridge self-supported under one static scheme until combined with the remaining portions,” he says.

Most engineers don’t want to speculate based on professional courtesy and lack of intimate knowledge of the design and construction. One engineer, based only on seeing the photos, notes that if the bridge had not been adequately designed to carry dead load, “it would have fallen the same day, not five days later. Something else happened on Thursday.”

Adds Hillman: “The important thing is to publicize the root cause when we know the specifics, so that we can learn as a profession and avoid jeopardizing public safety in the future.”

Concern About Post-Tensioning

Comments posted online and sent to ENR expressed concern about work with post-tensioning cable or bars being done without the contractors and FDOT shutting down traffic. But it isn’t clear if such work is prohibited or considered safety-critical once the main span is in place. FDOT had issued a permit for traffic control during installation of the structure days before the collapse. “Any testing done to the structure following its installation was the responsibility of the FIU design-build team,” FDOT said.

MCM-FIGG, in its 2015 project proposal, had outlined extensive safety measures. Those included dedicated pedestrian routes, staff certified in Advanced Work Zone Traffic control, minimized traffic shifts and lane closures “throughout the entire project,” coordination with the university and FDOT “for advance notification of any shifts or temporary lane closures and using barriers to separate vehicles, pedestrians and workers.”

Both FIGG s and MCM have thus far commented through statements. “FIGG Bridge Engineers Inc. continues to work diligently with the construction team to help determine the cause of the collapse,” the firm stated. “We are heartbroken by the loss of life and injuries.”

MCM stated that it “will conduct a full investigation to determine exactly what went wrong and will cooperate with investigators on scene in every way.”

Subcontractors were at work on different aspects of the project, too, and their roles are for now unclear. The design-build team’s 2015 proposal promised that once the main span was erected, “additional work to complete the main span construction will be performed over off-peak lane closures.” The tragic irony is that the bridge was being built to increase the safety of students crossing the road.

By Scott Judy, Richard Korman and Aileen Cho, with Jim Parsons

This story was amended March 27 to include a more accurate description of the bridge's truss and the overall design which included pipes with the appearance of cables extending from the unbuilt central pylon.

Post a comment to this article

Report Abusive Comment