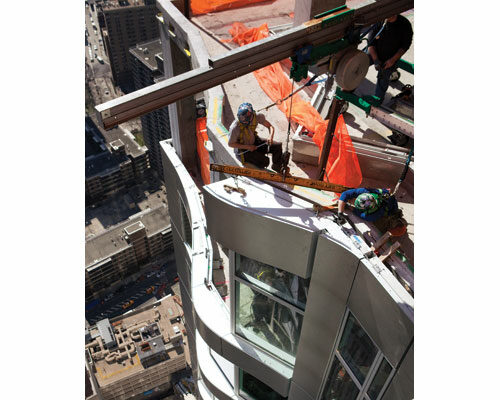

...began that fall. Panel installation started about a year ago and is scheduled to be topped out in September. “There is no appreciable cost premium for the ‘premium’ curtain wall,” says Rechichi.

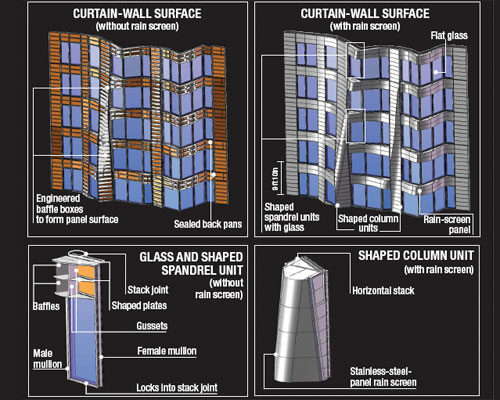

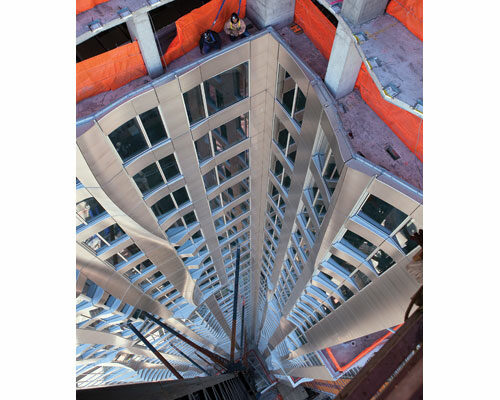

In the end, of 10,911 rectangular panels for 427,734 sq ft of the eight-sided tower, there are only 1,888 repetitive units. There are 1,568 shaped column-cover units, 2,178 flat column-cover units and 5,177 shaped spandrel units with glass. The 9-ft, 10-in.-tall units vary 3.5 ft to 7.5 ft in width. All the glass is flat.

Each shaped unit is unique. Permasteelisa managed to cold-bend 70% of the panels, mechanically rolling only the tighter geometries. Cold-bending, which is the most economical method, curves the metal to its yield point.

The curtain wall is made up of two primary components: an inner wall and a rain-screen panel assembly. All panels have interlocking male-female mullions and a mating horizontal stack. They also have anchoring clips that attach conventionally to embeds in the segmented edge slabs.

The inner wall, made of insulated glass, insulation and aluminum unitized panels, forms the primary weather barrier. The units are planar on the interior surface and segmented to follow the superstructure’s profile. For the columns and spandrel areas, outer rain-screen assemblies are made of formed stainless-steel sheets attached to ribbed aluminum substructures.

Unique Transition Stacking

No tower floor plates are alike. A unit’s gutter may be offset in or out from the unit below by nearly 5 ft. PNA developed an assembly to let the stack joints between floors shift in plane from floor to floor. This transition stacking is “unique for a unitized system,” says Budd. PNA submitted traditional 2D shop drawings to Gehry, with dimensions for only profiles. “If you want to check dimensions, you have to overlay the 3D models,” says Budd.

PNA uses CATIA for surface design and SolidWorks software drives the CNC cutters. PNA wrote its own material- resources-planning software for Disney, refined it for Interactive and revised it again for Beekman. “We have improved our ability to track these assemblies in the production process,” says Budd.

PNA provided load and structural reactions of the skin to the structural engineer. “I had to create a structure that would be able to take care of all the horizontal activities, independent of the dancing facade,” says Silvian Marcus, CEO of local structural engineer WSP Cantor Seinuk. Once that was done, he was able to play with the facade, he says.

Tower accelerations are controlled through stiffness and weight rather than dampers. The structure consists of a central core, perimeter columns and reinforced-concrete outrigger walls that span between the core and perimeter shear wall at mechanical levels six, 38 and 76. The outriggers, which are 1.5 ft to 2 ft thick, spread loads to perimeter framing and transfer loads from one column line to another as the building broadens toward the base. “The school has larger spans, which meant transferring out 90% of the columns above,” says Marcus.

Slab edges are in different planes every floor, but columns stay in the same plane for about eight to 12 floors, as a way to simplify the formwork. At “change” levels, columns broaden, encompassing the column location above and below.

The strategy avoided sloping columns, which have more complicated and laborious formwork. “If I had sloped columns for 76 floors, I would have killed the job,” says Marcus. “It’s a spec building, so I had to maintain the construction rhythm.”

Foundation work began in October 2006; superstructure work began in April 2008. Construction so far has had a few hiccups unrelated to the curtain wall. When the building was at the third floor, word spread of an investigation into regional concrete testing giant Testwell Laboratories, which ultimately was convicted of racketeering stemming from allegations it filed fake test results on more than 80 buildings in the area. Testwell was testing Beekman concrete. Without Testwell’s knowledge, FCRC had another testing firm check cylinders and compare them to Testwell’s. “We had to be prudent,” says Marcus.

When the frame was at the 27th floor, FCRC replaced Testwell. The structure was almost finished when the city began requiring protocols for Testwell-tested concrete. “We took additional cores, tested them and did all the necessary calculations,” says Marcus. “We found the concrete was according to the original specs.”

A bigger hiccup was related to the crippling economy. Last March, FCRC stopped construction and considered capping the frame at 40 stories because of financing and marketability issues. In May, a decision was made to...

Post a comment to this article

Report Abusive Comment