Blame the U.K.’s vote on June 23 to leave the European Union—the Brexit referendum—as well as construction challenges, for a hesitation in the drive to develop lightweight floating foundations for wind turbines sited in deep waters off the coasts of Scotland and England.

“The political situation is very uncertain in Scotland following Brexit,” says Bill Hurley, chairman of Glosten Associates, a naval architecture and marine engineering firm in Seattle and development director of PelaStar, one of two such projects that have been moving toward deployment in England and Scotland. “We’re surfing through political changes and challenges in the initial development of floating wind.”

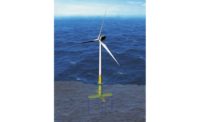

Three designs are moving through tests, including validation of their construction schemes. The designs are referred to as “tension leg platforms” for the way anchoring cables and the platforms’ semibuoyant, submerged foundations are held in tension to stabilize the foundations, turbines and rotors standing high above the open sea.

The tension leg platform is a lightweight and stable floating system once installed, but it is not stable without a mooring system connected. Constructors will need a transport and installation system to guarantee stability and safety of the platform during deployment, according to Offshore Renewable Energy (ORE) Catapult, a nonprofit offshore wind and tidal energy research center in Blyth, England.

The drivers for the development are economics and opportunity. “There are immense wind resources in water depths greater than 50 meters,” explains Hurley, “plus they have the benefit of higher wind quality and can be further from shore [and] out of view. The best wind sites in shallower waters are soon to be taken, so if offshore wind continues to prove a cost-competitive renewable energy source, it will move to deeper waters.”

With the current designs in development, floating foundations would become more cost effective than fixed-jacket foundations on the sea floor at sites somewhere between 40 m and 50 m deep, says Hurley. The competition now between the designs in development is to create stable designs of the lightest possible weight and to push the projected cost advantage over fixed foundations to even shallower waters of 30 m.

“Less steel weight is important for capital cost reduction,” says Hurley, adding that all of the floating concepts avoid the construction cost of jack-up barges and the large, expensive turbine installation vessels needed to set fixed foundations.

Hurley’s firm, Glosten, is involved in the most advanced project in terms of testing and regulatory certification, the 6-MW PelaStar system, which has been in development since 2006. The project has received more than $6 million in funding from the Energies Technologies Institute in the U.K. and $1 million from the U.S. Department of Energy.

“We’ve completed a FEED [front end engineering design] level of design and have a construction plan in place that is costed out,” Hurley says.

The PelaStar design has been tested at the Wave Hub Test Site off the coast of Cornwall, England, but the developers ran into permitting issues due to military radar interference and pulled out at the end of 2014. The Wave Hub Site claims to be the world’s largest and most technologically advanced grid-connected site for testing and development of offshore renewable energy technology. Its test field is 16 km offshore in the eastern edge of the Atlantic Ocean, with water depths ranging from 48 m (157 ft) to 58 m (190 ft).

“Floating wind is likely to be an extremely important technology as we aim to drive down the overall cost of renewable energy,” says Gavin Smart, an investment and financial analyst for ORE Catapult. The nonprofit, together with partners at Scotland’s University of Strathclyde, is participating in development of a £1-million ($1.3-million) tension-leg-platform wind project called TLPWIND. The project is led by Spain-based Iberdrola Engineering & Construction.

The TLPWIND Project’s floating foundation, which is similar to the PelaStar design, on June 26 successfully completed wave-tank testing of both the floating TLPWIND demonstrator and a floating construction support system at in a lab at Strathclyde. The lab simulated extreme ocean conditions found off the country’s northeast coast. The TLPWIND Project is designed for water depths of 81 m (266 ft).

The design for a 5-MW, 940-ton floating system was tested with a 1-to-36-scale model. The test tank replicated conditions off the Aberdeen coast of Scotland with up to 52-ft waves and 161-ft-per-second wind gusts.

Sandy Day, professor of marine hydrodynamics in the naval architecture ocean and marine engineering department at Strathclyde and director of the hydrodynamics lab said, “This technology has been shown to work and reduce cost. We carried out rigorous testing of the scale models and found that even under stressful conditions, the platform is both stable and robust.”

A 1-to-55-scale model of a semisubmersible barge to be used for transport and installation procedures also was tested. The results confirmed the viability of performing the transport operation for the TLP and the barge at up to 5 knots in a 2.5-m (8.2-ft) wave height, and installation operations in a 2-m (6.6-ft) wave height, according to an ORE Catapult document.

“Scaled model tests proved that the TLPWIND platform coupled with the semisubmersible barge was extremely stable with good seakeeping abilities during all transport and installation stages,” ORE Catapult reports.

ORE Catapult also has performed a “levelized cost of energy” (LCOE) analysis for TLPWIND, basing calculations on a 500-MW offshore farm in U.K. waters. LCOE is the full lifetime cost of producing each MWh of electricity, including all capital expenditure, all operating expenditure and decommissioning cost. It estimated an LCOE (in British pounds) of between £91/MWh and £95/MWh by 2025. But forecasts suggest that, with larger turbines the TLPWIND concept could deliver costs as low as £88/MWh by 2030 and potentially as low as £64/MWh by 2050.

A third TLP design is in development by Gicon, an independent group of engineering and consulting companies in Germany, Hurley says. Its developers are seeking to bring the cost point down even further in a bid to make floating foundations cost-competitive against fixed foundations in waters as shallow as 30 m.

Post a comment to this article

Report Abusive Comment