Energy companies and builders are laying a foundation for the next round of nuclear powerplants in the U.S., making serious commitments of almost $500 million in recent months. Similar to an overseas investment trend, assembly plants for new reactors will produce finished modules that will be shipped to nearby construction sites. Construction of the first modules—not expected to go online until 2017—is to begin next year.

The Shaw Group Inc. announced in August that it, with Monroeville, Pa.-based Westinghouse Electric Co., will construct a $100-million plant in Lake Charles, La., to build modular components for the 1,100-MW AP1000, Toshiba Westinghouse’s Generation III+ pressurized-water reactor. In October, Paris-based Areva NP announced it would work with Los Angeles’ Northrop Grumman Corp. at Newport News, Va., to build a $360-million facility to build components for its 1,600-MW U.S. Evolutionary Power Reactor. And GE-Hitachi Nuclear Energy, Wilmington, N.C., is in talks with several U.S. firms with experience in module fabrication to help build its 1,370-MW Gen.-III Advanced Boiling-Water Reactor.

“If things go the way they’re going, we’re going to be in heavy, heavy construction really soon,” says Jeffrey Hamel, senior project manager at the Electric Power Research Institute, Palo Alto, Calif. Robert Belk, executive vice president of Baton Rouge-based Shaw, says his company is eager to begin work on a backlog of four units, with the expectation of “several” more orders.

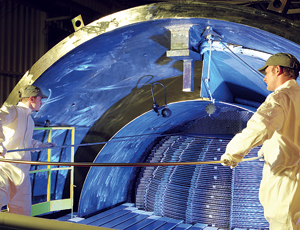

The new nuclear units will be built using a combination of offsite and onsite-built modules. GE-Hitachi will use up to 200 modules in each ABWR, according to Steve Hucik, vice president of ABWR projects. It built the world’s first Generation III nuclear unit on time and on budget in 1996, in Japan, and the use of modules was a success factor.

Modules allow large cranes to position components in the plants through “open top” construction, while also allowing parallel construction “in which multiple disciplines are coordinated, rather than working sequentially,” Hucik says. The offsite facilities maximize parallel construction, with room to expand work on modules for several units simultaneously. The method also provides a controlled environment and a stable workforce. That’s important because, while building processes are similar to nonnuclear construction, there will be about 50% more work because of the stringent nuclear specifications, Belk says.

The number of modules built offsite is limited by the ability to move them. Modules for the AP1000 are designed to be shipped, trucked or railed to a construction site where, in some cases, they will be assembled with other modules before being placed, Belk adds.

The largest module to be built in Lake Charles is 42 tons. Shaw expects to employ about 200 craft laborers in its 600,000-sq-ft facility by next fall. Areva and Northrop Grumman plan to begin building the 300,000-sq-ft Newport News facility next year. Its production of 500-ton components, including reactor vessels, steam generators and pressurizers, is expected to begin 36 months later.

Post a comment to this article

Report Abusive Comment