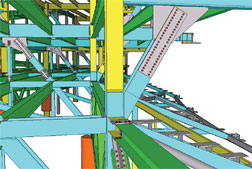

Thornton Tomasetti, Inc. Job cut into discrete design and construction sequences, beginning on right field side, to save six months.

|

“We’re probably pushing the limits of fast track,” says Rick “Buck” Buckovich, senior project manager for structural steel and precast for Clark/Hunt/Smoot (CHS). The Bethesda, Md.-based design-build joint venture is led by Clark Construction Group and includes Hunt Construction Group and Smoot Construction.

Despite fast-track’s drawbacks, which include redoing some work, “we felt we could do [this job] from the day we”signed the contract,” says Ron Strompf, CHS’s senior project superintendent.

The job is not only breaking records, it is making them. The 41,000-seat ballpark is likely to garner the distinction of being the first major league sports facility to achieve certification from the U.S. Green Building Council’s Leadership in Energy and Environmental Design (LEED) rating system.

|

Design-build, with preconstruction services and design-assist from major subcontractors, allowed CHS to break the ballpark into nine discrete, sequenced segments for purposes of both design and construction. The strategy saved six months in construction, say CHS executives. “It’s not unique to break a building into segments but it is unusual to design to those segments in the construction sequence and manage to start construction earlier,” says Alan Petrasek, a CHS project executive.

That put stress on the architect. “We were in schematics and they were building it, which is not an optimum arrangement,” says Susan Klumpp, project manager for the local joint venture architect HOK/Devrouax & Purnell Architects (HOK/DP). “It was really a hold-ontoyour- hat pace,” she says. Even in the interior fit-out stage, “it’s still tough,” she adds.

But because of CHS’s strategy, steel fabrication and erection took a year less than is customary, says Don Banker, president and CEO of Banker Steel Co. LLC, Lynchburg, Va. “Clark did a great job ‘policing’ the collaborative process,” says Banker, who explains he has seen the strategy fail with other design-build contractors because of weak leadership. “Thanks to Buck, everyone had their marching orders when they left the meetings,” says Banker.

Ballpark is the first in the major leagues designed to conserve energy.

|

The design-assist process “brought everybody’s issues to the table in real time,” adds Mark J. Tamaro, project manager for the local structural engineer, Restl/Thornton Tomasetti Joint Venture. “We could use the contractors’ skills to optimize system selection based on schedule instead of speculating or making assumptions about construction.”

Key to the process were weekly structural design meetings, which started in the preconstruction phase. Everyone from the steel detailer to structural precaster R.W. Sidley, Thompson, Ohio, put their heads together at the meetings to determine the best way to expedite the schedule while keeping within the budget. “It was great,” says Versie Stephenson, structural coordinator for HOK/PD. “Usually, we get through CDs before the subs are on board,” he says.

A 3D digital model for the structural steel helped the team, cutting two months off the project’s timeline and decrease structural requests for information to about 10% of what is usual, according to team leaders. “The bottom line is that the job could not have been completed for the 2008 season using traditional methods,” says Matthew T. Haas, a CHS project executive.

Mountain Enterprises, Inc. |

Digital model helped save two months.

|

Thornton Tomasetti pioneered the use of a digital model on Chicago’s Soldier Field football stadium, which opened in 2003. The ballpark job, TT’s second building information model (BIM) for a sports job, was a much better experience because all team members supported its use, says the engineer.

Using the model at the design-assist meetings, the team worked out complex geometries of exposed connections to satisfy the architect’s aesthetic requirements and the engineer’s safety requirements. The steel detailer’s favorite part of the work was talking directly to the architect, something that rarely happens. “We had long meetings about [variations in] slab thickness” and its impact on the position of the steel supports, says steel detailer John Shaw, president of Sharpsville, Md.- based Mountain Enterprises.

Beginning

Ballpark design started in May 2005 for owner D.C. Sports & Entertainment Commission. CHS, which was selected in August 2005 for preconstruction work, signed its contract with DCSEC in March 2006 after submitting a $344-million guaranteed maximum price in late January 2006. That was at the end of schematic design and nine months earlier than anticipated, says CHS.

Based on CHS’s guaranteed maximum price, the District of Columbia funded the project in February 2006. The ballpark’s revenue bonds, secured by sales tax from the ballpark, other tax revenue and the team’s annual rent, were sold in May 2006. Altogether, the district borrowed $534.8 million.

DCSEC took control of the site in March 2006. That also marked the beginning of demolition work on existing buildings and remediation of the brownfield site, near the Anacostia River. Some 337,000 tons of contaminated soil have been removed.

Workers began excavation on May 4, 2006, just a couple of days after the Lerner Group bought the team from the owners of major league baseball. Steel erection...

ith only 23 months to complete all the bases, the team building the 85%-complete D.C. Major League baseball park is getting very close to hitting construction's equivalent of a grand slam off a 100-mph pitch. If it opens April 1 as planned, the $611-million home for the Washington Nationals will break the speed record for major-league ballpark construction. Related Links:

Related Links:

Post a comment to this article

Report Abusive Comment