Almost four months after a deadly explosion halted work on a nearly $1-billion Connecticut powerplant under construction, developer Kleen Energy Systems LLC, Middletown, Conn., says the 620-MW gas-fired facility may be repaired and ready for operation next spring. But the U.S. Chemical Safety Board says it has found that “a disturbing number of companies” use the gas-blow pipe-cleaning process that led to the Feb. 7 explosion, which killed six workers and injured 50.

Gas blows remain the most common single practice to clean debris from powerplant pipes, according to the board. A recent survey by the board found the practice used routinely by 37% of the 62 gas-fired powerplants that responded, and, on occasion, by nearly two-thirds of the facilities surveyed.

Despite safety warnings issued by the board following the explosion, the practice continues, according to the board. “The industry survey confirms that there are readily available safe alternatives to using flammable natural gas for pipe cleaning,” says Dan Tillema, a board investigator. “At the same time, a disturbing number of companies continue to use natural gas, which creates the serious risk of a fire or explosion.” Safer approaches employ use of air, steam, non-flammable nitrogen or other pipe-cleaning tools, according to the agency.

Board investigators have yet to pinpoint the exact cause of the Kleen Energy blast but found several possible ignition sources at the construction site. Gas blows also can cause explosions when ejected debris hits nearby objects and creates sparks.

Equipment suppliers Siemens Power Generation, Vogt Power International and others are continuing to assess plant damage and replace equipment, a process that has been slowed because pending litigation gave Kleen Energy only limited access to the site until mid-April.

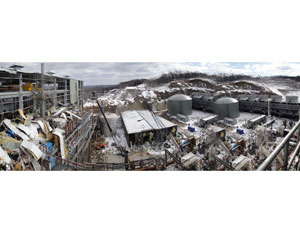

The developer’s preliminary visual inspection showed “significant damage to relatively minor equipment” around the heat-recovery steam generators, according to the company’s April report to the Connecticut Siting Council. It contends the plant might be in commercial operation by next April.

Since then, Siemens “has not identified any significant issues” in its inspection of the plant’s turbines, according to a May 21 Kleen Energy report to the state Dept. of Public Utility Control. Siemens has replaced several auxiliary skids in the combustion turbines. Vogt has begun restoring the heat-recovery steam generator in the plant’s Unit 1 and awaits full removal of debris in Unit 2 so it can finish assessing damage.

Owned by Energy Investors Funds and White Rock Holdings, Kleen Energy was 93% complete and ahead of schedule when the blast occurred. Torrington, Conn.-based O&G Industries is the project contractor.

Connecticut lawmakers had introduced a bill after the blast that would have required state agencies to develop joint standards for powerplant safety, but they were unable to pass it before the end of the legislative session in early May.

Post a comment to this article

Report Abusive Comment