...pressure is building to require more tests. But careful examination of the process shows that passing a test is not the only critical thing a crane worker needs.

Building Experience

Experience is another factor. Few jurisdictions that require a license require a minimum level of experience. “It’s easy for a guy to read a book, be told some key answers, and pass a written exam—no insult intended—and then sit in a seat for a week and be able to safely move a load,” says Howard Kaplan, safety manager for Phoenix-based Southwest Industrial Rigging. Kaplan, a competitor of Gray’s crane school, came to Apache Junction to audit Gray’s test procedures in a sort of peer review. While he was taking notes, we talked about what it takes to be a safe and productive operator. “Pulling levers is a small part of it,” he said, adding that not all training is created equal, either. “Other than Ronnie, ask some instructors when was the last time they rigged a real load.”

Even if the federal standard is never implemented, project managers are building a culture of certification. “We are looking at walking down the road of ensuring that all our subcontractors have CCO certification,” says Shawn King, manager of environmental safety, health and security for Overland Park, Kan.-based Black & Veatch. “I don’t think that it is a catchall by any means, but it is going to help.” Having managers trained in basic crane skills also fosters safety on a project, he adds.

Guy Lawernce/ENR

| “You can never get too much training.” — KEITH CRAWFORD, CRANE FOREMAN, HENSEL PHELPS CONSTRUCTION CO., BEDFORD, TEXAS

|

For operators, standardized testing is “a step in the right direction because it does teach you the basics,” but it is also “just like taking a kid and running him through a driving school,” says Clyde Raper, equipment superintendent for Perini Building Co. in Las Vegas. “Knowledge of the laws, that’s one thing, and then what makes a good crane operator after that is experience.”

Raper cites a problem he had with an operator from Gray’s school who went to work on the complicated CityCenter project on the Strip. “He had four-and-a-half hours in the seat but he was legal to operate a crane in the State of Nevada, says Raper. “He couldn’t run the damned crane.”

In Nevada, an unlicensed operator can work under the watch of a licensed one. So Raper yanked the card-carrying operator out of the seat and made him a supervisor, using his license to train other “provisional” operators who showed more promise.

According to the teacher, the student was not teachable. “I kicked him out of the school,” Gray says. “He came back and told me his life story, so I let him come back. Then, the whole school’s reputation was balanced on that one guy. I called Clyde and said I’m sorry: I should have never let him back in.”

Worker pride is another growing pain. “People resent that I do in two weeks what takes the unions two years. But just because you have all these years of experience doesn’t mean you have everything you need,” says Gray. Some experienced operators “feel like they are being put in the same bag as those with less experience,” Brent adds. “We’re not doing that. Experience is another layer; it’s absolutely critical.”

Trainers themselves often feel conflicted over the experience factor. “My only criticism of the CCO has been that you can have a nationally recognized certification to run a crane after only a week’s worth of training,” Kaplan says. “What people have to understand is that this is the beginning, not the end.”

| + click to enlarge |

Guy Lawernce/ENR Operators are timed while performing the four tasks.

|

| + click to enlarge |

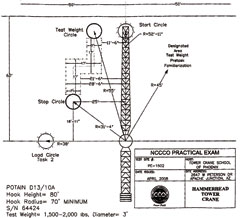

Tower Crane School Of Phoenix Practical Exam Layout

|

Aside from experience, costs also are a common complaint. “The thing that really disturbs me about CCO is they are charging $4,000, says Bill Waggoner, business manager of Local 12 in Pasadena, Calif. “The only thing they are interested in is the money. They don’t care if the guy can run a crane or not.”

In reality, the test is a small price to pay. Agencies like NCCCO charge a few hundred dollars to administer the exams. I took the 55-question written exam, costing $165, and the 20-minute-long practical exam, $60. The fees were built into Gray’s 60-hour package, which cost $4,635 plus travel expenses. Far more money is tied up in diesel fuel and the equipment itself, which is expensive to own and operate. “All too often,” Kaplan says, training “goes to the lowest bidder.”

Costs are hard to ignore. So in 2005, when California started requiring all crane operators there to be certified, Local 12 gained national accreditation from an examination board. At the same time, it also mandated that its union members have at least 2,000 hours of crane-related experience before they take the test. “It’s more strict than NCCCO,” Waggoner says.

The union showed “that the system is open to anybody,” Brent said at the time. Since then, California public-safety officials have studied licensing effects and found that fatal accidents involving cranes decreased 80% in 2005-2008 over 2002-2005. Nonfatal accidents also decreased by 57%. Local 150 in Chicago adopted the Local 12 model this year, while other locals still use NCCCO exams, which have no experience requirement. NCCCO requires 1,000 hours of “crane-related experience” to recertify. It dropped a similar mandate for first-time candidates in 2007 because verifying employment proved difficult.

“We’re not an employment agency, we are a testing agency,” Brent explains. Today, NCCCO candidates must only pass a physical and substance-abuse exam before taking the crane exam, though the agency does not collect medical data unless an operator is investigated for misconduct. So far, only a handful have been investigated, Brent says.

Experience may be tough to measure because it goes well beyond the scope of the test. “People have to understand that it’s not a license to be an expert, it’s a license to get supervised experience,” says Tracy Bennett, editor of Crane Hot Line, which recognized Gray this year as one of America’s top trainers. Patrick Stafford, owner of Stafford Tower Cranes and Gray’s business partner, agrees: “When you get your pilot’s license, they hand you a card and say, ‘Congratulations, you now have a license to learn.’”

Learning to Fly

My first turn at the stick was a complete disaster. Reading books and bubbling answers on a Scantron sheet with a No. 2 pencil is no big deal, but operating a crane is a bigger animal. Gray gave us useful advice: “Catching your load is what crane operation is all about.”

We previewed the controls: Trolley and swing on the left. Hoist on the right. Simple enough. “Keep it in first step all the way through the course,” Gray said, referring to telltale “bumps” in the joysticks, indicating speed. Then, he quickly ran the hook loaded with a 1,800-lb test weight—a steel cylinder filled with sand—through a 51-ft-long, 7-ft-wide, zigzag shaped obstacle course. It was the same corridor we would need to negotiate to complete our practical exam (see illustration). Gray did it in less than 30 seconds. We would have three minutes for the test.

Guy Lawrence/ENR Gray's school teaches students more than how to take the NCCCO exam, including sessions on basic rigging and crane-setup skills.

|

On the ground below, I took note of a strange, Z-shaped pattern of orange poles topped with tennis balls and two landing circles on either side of the corridor. Test critics bring up those tennis balls as a reason why the test is out of touch. “The challenge is to take a real-life situation and make it measurable,” Brent responds. A pole could be an ironworker, and a ball could be a limb. Examiners take off a few points when candidates knock off a ball, several points for a pole. The reality is far more serious.

You have to be able to maneuver the height, radius and swing of the load to navigate the course. Brent and others say it tests your ability to do multiple functions at once. But I found that you have plenty of time to swing, trolley and hoist separately. Experienced operators can do it at the same time, as Gray proved.

Even doing it the “easy” way is a lot harder than it looks. But the basic principles of load control also apply to mobile cranes, which are more complicated than tower cranes because their boom angle changes load height and radius, while on tower cranes, excepting boom-operated “luffers,” height remains mostly fixed.

As I tried to navigate the obstacle course, my load swung wildly from side to side as I engaged the swing gear, then rolled forward and back whenever I trolleyed. After I killed most of the poles, a voice came over the radio. “Looks like we need to spend some time on load control.” I repeatedly tried to catch the load by moving it out, waiting, then moving it out some more. It worked, but I was still not operating smoothly. Never mind that the crane bobbed up and down and torqued from side to side, tweaking my nerves. After a few more tries, I made the load hover quietly over its target. Soon enough, I was navigating the course in a slow-and-steady movement Gray called “walking the dog.” Being able to control the load is surprisingly gratifying. Like riding a bicycle, it is at that point when you begin operating the machine, instead of the machine operating you.

Days later and after 10 hours in the seat, I was ready for my final exam. My heart was still pounding from the climb and only quickened as I noticed the man on the ground holding a stopwatch. Taking a deep breath, I flashed a thumbs-up and highballed the hoist. When I was done, only a couple of balls were missing. During the week, I learned more than how to take this test. Gray had us fly concrete buckets, steel and wall forms. Skills transfer from crane to crane: I ran a telescopic truck crane through the obstacle course, only knocking over a few tennis balls.

Certification is not immediate. It took me a month to reserve my spot in the class. Two weeks after I took the test, I received a letter in the mail from IAI. I scored 94% on the written exam. By the end of October, I still had no practical scores. They can take up to a month and a half, at which time the certificate also arrives. This is frustrating for workers waiting to get to work, Gray says.

Perhaps this wait was my next test: patience. Speed and safety are often at odds, but training can help balance them. Testing shows you have the basics. “You have shown that you have the potential to become a crane operator,” Gray told me. Even the most experienced operators should always be learning. “I think when you get to the point where you can’t be taught anything, you are destined for a major accident.” Crawford adds: “You can never get too much training.”

Post a comment to this article

Report Abusive Comment