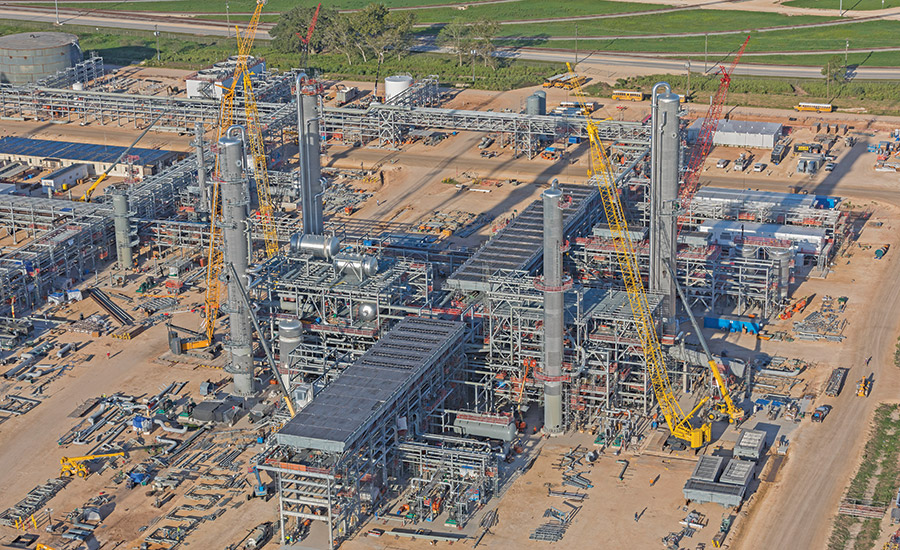

Sweeny Hub, Phase 2 Expansion (SHP-2)

Sweeny, Texas

BEST PROJECT and Award of Merit, Safety

OWNER: Phillips 66

LEAD DESIGN FIRM/GENERAL CONTRACTOR: S&B Engineers and Constructors Ltd.

SUBCONTRACTORS: Dashiell LLC; Remedial Construction Services LP

The $1.4-billion expansion of the Phillips 66 natural gas liquids complex in Sweeny, Texas, transformed the facility into one of the nation’s largest NGL processing hubs and quadrupled the site’s capacity.

Challenged by hurricanes and a global pandemic, S&B Engineers and Constructors completed the massive project two months ahead of schedule and $100 million under budget.

Photo courtesy of Phillips 66

S&B applied best practices and lessons learned in designing and constructing 20 other NGL plants and, working with Phillips 66, found more than $300 million in cost reductions. Additional savings came by eliminating unnecessary infrastructure.

Another challenge was avoiding interruptions at Phillips 66’s adjacent refinery, which was in full operation throughout construction. The team developed a “greenfield islanding plan,” which included locating the construction site next to, not within, the existing refinery. This maximized construction efficiency and minimized impacts to the refinery’s operations.

Photo courtesy of S&B Engineers and Constructors Ltd.

The project was identified as one of the safest megaprojects in Phillips 66 history, with a recordable injury/illness rate 33 times better than the national average. With more than 4,000 contract employees over the course of the job and a peak of 2,500 during the COVID-19 pandemic, the project totaled 4 million worker hours without a recordable incident.

The team created a project-specific COVID-19 workflow plan and made adjustments based on feedback as work progressed. Best practices included screening, social distancing, masking and hand sanitizing stations. Schedules were adjusted to stagger personnel and keep large groups from forming. There were four separate start times, buses to the site were kept at 25% capacity or less and the team added additional lunch breaks with 20 open lunch tents spread across the site.

Post a comment to this article

Report Abusive Comment