In its 42 years, Alta High School in Sandy, Utah, about 17 miles south of Salt Lake City, has seen a big evolution in teaching technology, some demographic shifts and a change in school districts.

The school is now part of the Canyons School District, created in 2009 to serve the fast-growing communities at the southeastern corner of the Salt Lake Valley. Alta High School currently has an enrollment of around 2,300 students.

In addition to joining the new district, the school was affected by changes in state policy around the same time that gave students and families more choice about what schools to attend. That, in turn, drew students to newer facilities with more amenities than the district’s older buildings. That’s among the reasons why Alta High School is currently undergoing a $54-million expansion and renovation, funded by two voter-approved bond measures. The multiphase project began in 2013.

“We did an architectural review of all the facilities that became part of the Canyons District in the spring of 2009,” says Jeff Haney, communications director for the Canyons School District. In addition to an HVAC system that required updating, Haney says Alta High also needed new gathering spaces, teacher collaboration spaces, better security and improved way-finding.

Jeanne Jackson, principal and lead design architect at Salt Lake City-based VCBO Architecture, says features like performing arts spaces and athletic training facilities that have drawn students to newer schools also were ready for upgrades in the 42-year-old building.

VCBO found that while the school had been remodeled previously, the “bones of the building were in good condition.” The decision was made to design a major renovation rather than a complete replacement. That not only made financial sense but also would be less disruptive for students, faculty and the community, the design firm says.

Putting on a Show

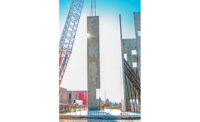

The largest and most challenging feature of the expansion and renovation is the creation of a freestanding performing arts building, which is rising on the northwest corner of the campus on a former sloped parking lot. A distinctive crown on the 62,431-sq-ft building has alternating gray, black and white aluminum composite materials (ACM) panels, while a horizontal band of red metal separates the upper third of the structure.

The main south-facing entry of the building is covered by an overhang with a reflective underside, and a two-story curtain wall fronts the lobby space and its polished black concrete floor. The centerpiece of the performing arts center is a 1,400-seat auditorium with a stage and fly loft that reaches a height of just over 75 ft.

“The architect was looking at 12-inch block for the wall, and there were only a handful of masons that wanted to do that. They didn’t want their people up that high with that size of block,” says Tom Preston, project manager for Hughes General Contractors, the CM/GC for the project.

Instead, the building team proposed using tilt-up panels that could be cast on site. “[The people at Hughes] are really the tilt-up experts,” Jackson says. “It looked like it could work and, in the end, it saved us about a million dollars and loads of schedule time.”

Accomplishing the task meant Hughes would cast 65 separate panels, the largest standing 75 ft 8 in. tall and the heaviest weighing just over 65 tons.

“At the time, they were the tallest panels in the state and the 10th or 11th tallest in the nation.”

– Tom Preston, Project Manager, Hughes General Contractors

“They were the tallest panels we’d ever done,” Preston says. “At the time, they were the tallest panels in the state and the 10th or 11th tallest in the nation.”

The crew already had leveled the site and placed the slab for the stage and the backstage portions of the building, so the casting beds were placed there. Architects designed a pattern of textured, horizontal layers in the form liner for panels that would be exposed on the inside.

According to Justin Marriott, Hughes’ superintendent for the project, the panels were also cast with beveled edges since some would have to be joined at slight angles to form the elliptically shaped auditorium.

“We are basically doing three buildings,” Marriott says. “You have this interior concrete structure, and all the tilt panels are structural. Then you have the exterior steel frame around it and then the ellipse on top.”

Marriott says the lift sequence was one of the more challenging aspects of the job, along with finding room for the tilt-up braces. The panels that make up the proscenium stage connect at a corner to panels that frame the backstage portion of the building, creating a tight corner for the braces.

“We had to use two cranes for a while, one to stand up the panels and then another to lift braces because we had to thread them in between each other,” he says.

Marriott says in order to work on the interior of the auditorium after all the panels were set, the team left a hole in one panel large enough to bring equipment through.

“We brought in a crane to set the ceiling joists, and we had to bring in concrete pumps to put in the floor. We had to have lifts to set the acoustic panels where they needed to be,” he says.

“We set up a total station in the middle of the room to shoot the lines to get the acoustic panels at the [proper] angles. Just about everything in here had to be finished before we could move the equipment out and close up that hole. Sequencing everything from setting the panels to finishing and getting going on the steel around the outside has been one of the biggest challenges,” Marriott says.

Moving Pieces

People and spaces had to be carefully shuffled to allow for renovations, Preston says. Once the performing arts space is complete, band, choir and drama programs will move in, allowing crews to renovate the former spaces into new administrative offices near the main entrance. A secure vestibule will be built as a single entry point adjacent to the administrative offices.

“We’re also redoing the commons area, which now has a low ceiling, is dark and there is no natural light. It’s not an inviting place,” Jackson says. “We’re going to raise the roof and put some clerestory windows in with views of the mountains.”

“We had to use two cranes for a while, one to stand up the panels and then another to lift braces because we had to thread them between each other.”

– Justin Marriott, Superintendent, Hughes General Contractors

Crews have closed off the commons area, and footings for new columns have been placed. The new steel columns will be lowered through holes cut in the existing roof and then secured.

“Once those are set, we’ll build the new roof with the clerestory windows over the top of the old one, then tear out the old one,” Preston says.

Last summer, crews installed more than 100 solar tubes in second-story classroom spaces that lacked natural light. New LED lighting and HVAC systems also were put in place. Since the performing arts building is designed to operate independently, it has its own high-capacity, low-velocity HVAC system to help minimize background noise.

Once the performing arts programs and their equipment are moved to the new building, Preston says crews will begin to remodel the existing auditorium, which will become a smaller black box theater. Band and choral programs will move into the new space as well.

A new indoor athletic practice facility with artificial turf was constructed last year. The 16,873-sq-ft metal building was placed at the north end zone of the football field, west of the main school building. The space includes an upper-level deck that overlooks the indoor field on one side, while full-height windows on the opposite side face the outdoor field.

Jackson notes that during an earlier phase of the work, the lights for the football field were changed out for more energy-efficient LEDs. “This space can be used for everything from football practice to baseball, golf or cheerleading,” Jackson says. The students even held a dance in the facility.

“The new performing arts center has been built to serve as a community gathering space,” Haney says. “Canyons District provides community access to gyms, and our playing fields are also used by Little League players and clubs.”

The performing arts center is scheduled to open this spring, and the entire project is slated for completion in time for the 2021 school year.