With an estimated 1,000 people relocating to Texas daily, clogged and bogged-down highways are commonplace, especially Interstate 35 through Austin, the state capital. For example, roughly 200,000 vehicles travel the Austin stretch of I-35 each day. The Texas Dept. of Transportation (TxDOT) projects a doubling of that number to more than 400,000 over the next two decades. To halt some of that congestion, TxDOT has earmarked more than a billion dollars for the ambitious Capital Express Program, a three-pronged project that will eventually widen and otherwise improve nearly 30 miles of heavily traveled roadway.

In addition to adding needed capacity, the city believes the project will also go far in righting a historical wrong. Originally built in the 1950s, I-35 served as Austin’s racial dividing line. “Austin has long since removed the segregationist language from its legal code and land use plan, but the physical barrier has remained,” the city’s project website states. “The redesign and construction of the new I-35 Capital Express has a role to play in rectifying this historical inequity for Central Texas.”

Fluor construction crews place barriers along I-35 in Austin as part of the Capital Express South project. The massive project is divided into three contracts: south, central and north.

Photo courtesy of Fluor

The three sections, known as the North, Central and South projects, will reconstruct I-35 while improving safety, mobility and east-west connectivity needs, TxDOT says.

In May 2022, Fluor was awarded the South project, which runs for approximately nine miles from US 290 West/SH71/Ben White Boulevard to SH 45 Southeast.

TxDOT said the roughly $550-million project came about after population and employment growth increased the area’s congestion. Construction started in March 2023 and substantial completion is slated for late 2027.

The project is slated to include two non-tolled high-occupancy vehicle lanes (HOV) headed each way. The project will also reconstruct bridges, add pedestrian and bicycle paths and make additional safety and mobility improvements within the project limits.

The required environmental justice study conducted by the University of Texas Center for Transportation Research found this section of the South project “would not substantially increase the separation of the community.” Since 1995, the area has seen rapid development. Today, the communities along this section have “similar minority distribution and character,” the report found.

“What makes this project different is the magnitude and time frame compared to the majority of TxDOT bid-build projects.”

—Matthew Krein, Project Director, Fluor

The North section of the project will reconstruct about nine miles of highway. The project will also reconstruct six bridges, add one non-toll HOV lane in each direction and build a diverging-diamond interchange and pedestrian and bicycle paths.

This section, which has an estimated cost of $600 million, broke ground in March 2023, with completion slated for late 2028. Pulice Construction is the general contractor leading this section. It runs from State Highway 45 North to US 290 East.

TxDOT is currently finalizing design on the Central project, which extends roughly eight miles through the central region of the Austin metro area. This project runs between US 290 East and State Highway 71/Ben White Boulevard.

The department’s website gives an anticipated construction start in late 2025. The project includes removing the existing I-35 upper decks of the highway, lowering the roadway and adding two high-occupancy vehicles lanes in each direction. It will also reconstruct east-west cross-street bridges and add walking and bike paths.

Preparations started in March 2022 for the nine-mile stretch of I-35's Capital Express South project. Crews from Fluor level the roadway to start construction.

Photo courtesy of Fluor

South Challenges

Several months into the southern portion of the project, Fluor is moving forward with its work. In that time, issues have already popped up, creating challenges related to property owners, utility companies and other various stakeholders located along the highly congested urban corridor.

“What makes this project different is the magnitude and time frame compared to the majority of TxDOT bid-build projects,” says Matthew Krein, Fluor’s I-35 project director.

The biggest challenge, Krein says, is constructing a 2.25-mile elevated bridge being built in the existing median of the main north-south I-35 corridor a few miles south of downtown Austin. The 30-ft by 60-ft bridge will include four managed lanes, two northbound and two southbound.

In an effort to reduce traffic impacts, TxDOT has limited lane closures to nights and weekends for various aspects of the construction.

“The challenge is not only in mobilizing all material into the high traffic corridor, but also storing equipment and materials in this narrow strip with freeway traffic passing on both sides,” he says, adding that when installing the 30-ft-wide footings in the middle of this construction zone, there is only 15 ft on either side of the footing for equipment access.

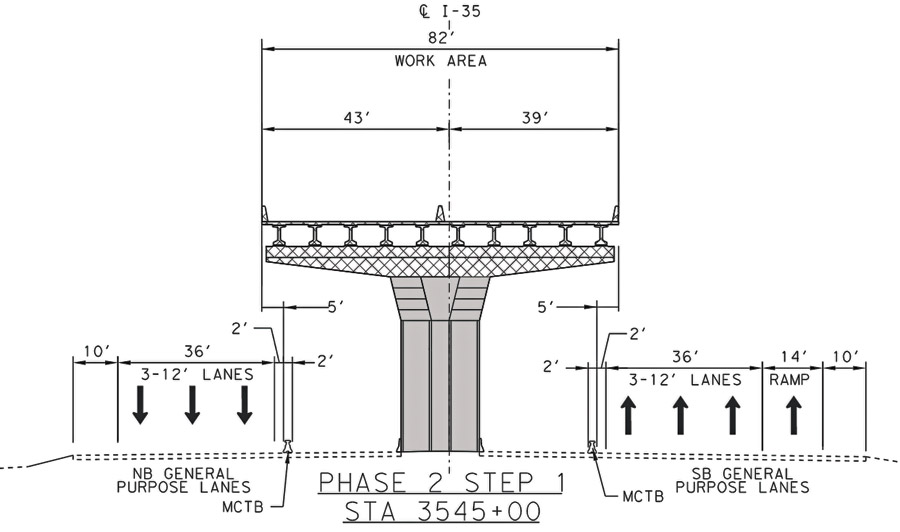

A drawing of an elevated bridge that is part of the project. Fluor says building the bridge is one of the project's biggest challenges.

Image courtesy of Fluor

The bridge caps overhang traffic, which also presents a challenge in the narrow median and in designing and installing cap formwork that doesn’t impact traffic during the day but that also carries the typical 82-ft-wide bridge above.

“Every aspect of the bridge from the footing, column, cap, precast girders/panels and the concrete deck placement are challenging due to the extremely narrow construction zone and the limited allowable lane closures,” he says.

He explains the complexity of constructing the bridge. The 10-ft by 30-ft footings require crews to typically excavate a 10-ft to 15 ft-deep hole in the middle of the work zone, posing even more logistical challenges, such as the high number of vehicles traveling closely to the barrier running on both side of the elevated managed lane construction work zone.

On the other hand, mobile concrete traffic barriers, running on each side of the median—where Fluor crews are primarily working—is improving efficiency by allowing the contractor to open up a larger area at night. This zipper barrier moves to widen the work area, giving crews the additional area in which to work during nighttime hours.

This rail can be shifted up to 12 ft—the width of one lane—at a time. The construction work area will be opened at night for the crews by shifting the zipper rail out, thus closing traffic lanes, and allowing critical bent cap and precast concrete girder erection to occur, Krein explains.

Fluor has worked with its steel bridge supplier W&W-AFCO Steel LLC - Hirschfield Division to fabricate these steel bent caps early and has started to set them where needed on site. The steel bent caps can be set utilizing allowable closure windows in the narrow corridor. “The need for falsework shoring is eliminated with this method,” says Krein.

Fluor work crews prepare for construction of the Capital Express South. The project started in March this year and is expected to be complete in late 2027.

Photo courtesy of Fluor

Safety

With safety at the forefront of all of its projects, Fluor is using technology to protect its work crews. The projects are utilizing intelligent transportation systems (ITS) to help improve public safety and mobility in highway work zones. Sometimes called Smart Work Zone, the system leverages information from its ITS equipment to improve safety and operations around the work zone.

The critical smart work zone items being implemented are temporary incident detection and surveillance systems that cover both direction of travel. These systems use detection points for queue detection and to determine travel times or speed monitoring. These consist of sensors on portable construction message boards and other locations to quickly notify TxDOT, Fluor and the public of any traffic impacts on the project.

Also being used are shared-used paths, which provide a paved, off-road travel area for non-motorized users, such as walkers, bikers and joggers.

Though both the availability and cost of materials has improved slightly recently, “We have attempted to mitigate some of that cost and schedule risk by working with subs/suppliers to purchase materials early under TxDOT’s material on hand (MOH) clause,” Krein said in a written response.

![SE Connector Anglin DR[6] copy.jpg SE Connector Anglin DR[6] copy.jpg](https://www.enr.com/ext/resources/2022/04/19/SE-Connector-Anglin-DR%5b6%5d-copy.jpg?height=200&t=1650550499&width=200)

Post a comment to this article

Report Abusive Comment