Midwest specialty contracting firms are continuing to face the challenges of a post-pandemic world led by market and economic uncertainty, according to respondents of ENR Midwest’s annual survey of specialty contractors.

Related Link:

ENR Midwest 2022 Top Specialty Contractors

Despite the various and continuing market challenges, companies reported some level of revenue recovery during 2021 compared with the year prior. Forty-four firms responded to the annual survey and reported a total of $6.29 billion in 2021 revenue, up from the $5.48 billion that was reported a year ago.

ENR Midwest’s Top Specialty Contractors survey covers the 11-state area of Illinois, Indiana, Iowa, Kansas, Kentucky, Michigan, Minnesota, Missouri, Nebraska, Ohio and Wisconsin.

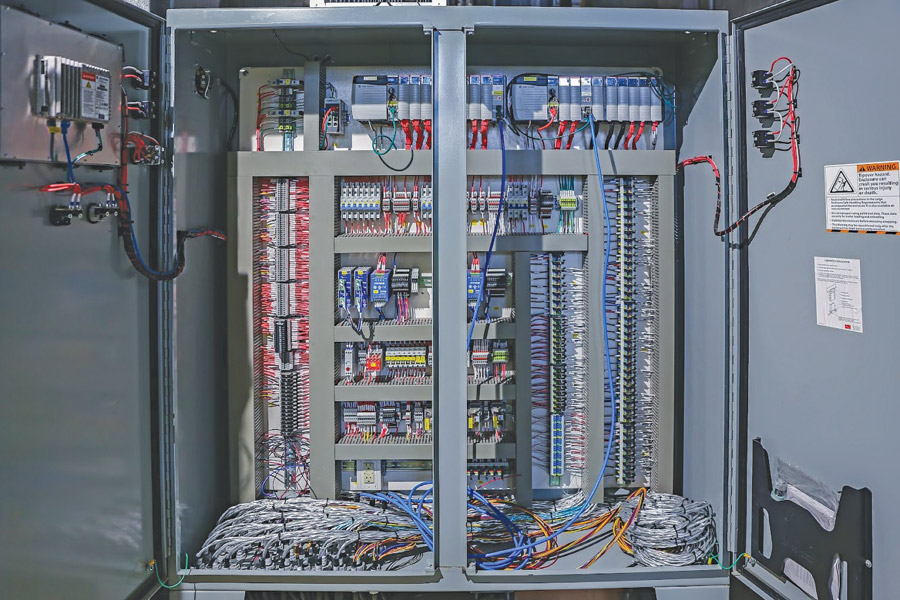

Buist Electric provided power and wiring at a paper packaging plant project.

Photo courtesy of Buist Electric

For many firms, 2021-22 has been a case of out of the frying pan, into the fire. While many specialty contractors held tight on projects throughout the height of the COVID-19 pandemic in 2020-21, the wind-down of the public health crisis has led to those same firms dealing with a range of issues including inflation, increasing interest rates, labor shortages and supply chain issues.

Scott Bishop, chief financial officer at Buist Electric, Byron Center, Mich., says although inflation and interest rate hikes are concerns, he believes the biggest challenge is the supply chain issue.

“When we bid jobs, once that PO is in hand, we order everything immediately to lock down the price,” says Bishop. “If we don’t, in some areas, the price can go up 30%, and you don’t want to get hit with that escalation. We’re holding down more items in stock than we would historically.”

Buist Electric dealt with supply chain issues in a project for Graphic Packaging International in Kalamazoo, Mich.

Photo courtesy of Buist Electric

Bishop says 95% of Buist’s work is in western Michigan. The firm has worked with such area firms as Amway, Kellogg’s, Spectrum Health and Steelcase.

One project that Buist worked on that presented supply chain issues was in Kalamazoo, Mich., for Graphic Packaging International, a manufacturer of paperboard and paper-based packaging.

A key component of the company’s $600-million expansion was the boiler house, which is integral to generating steam for power and process systems throughout the mill. The stand-alone, two-story, 32,500-sq-ft building houses two new natural gas-fired boilers.

Buist, which provided the power, wiring and most of the electrical and mechanical instrumentation for the project, dodged supply chain delays by maintaining most of the materials needed at hand, says contracting department manager Aaron Cooper.

“We’ve broken down our book of business and looked at real growth versus inflation, which are worlds apart.”

—Tony Ahern, President & COO, J.F. Ahern

Cooper says the firm committed more than 70,000 man-hours to the Graphic Packaging project.

Like other firms, Castle Contracting of Webster Groves, Mo., is navigating pricing issues.

“Oil pricing is up, concrete is up. The cost impacts of just getting materials from one point to another has been a challenge,” says Mike Pranger, senior vice president at Castle. “We had to look at our fleet on a national scale so we’re not limited to local vendors. We make sure that as we flex, we own the right amount of equipment. It’s not as easy as it used to be.”

Strategic use of its national fleet has helped keep a lid on fuel costs.

“Utilizing the strength of our national presence and the equipment fleet as a whole, we can make the best decisions on how to utilize our fleet to service our customers, no matter where the project,” he says.

Castle Contracting of Webster Groves, Mo., is building tiny homes for veterans in North St. Louis.

Images courtesy of Castle Contracting

While specialty contractors face many market challenges, some companies excelled in 2021. J.F. Ahern in Fond du Lac, Wis., reported 2021 regional revenue of $347 million, up from the $312 million it reported for 2020.

Tripp Ahern, chairman and CEO of J.F. Ahern, says his company’s performance was due in part to the overall strong economy.

Tony Ahern, president and COO, says the company is concerned that inflation is growing at a higher rate than their own growth rate.

“From the inflation point of view, we’ve looked hard at that,” Ahern says. “We broke down our book of business and looked at real growth versus inflation growth, and those two are worlds apart.”

While the firm’s revenue grew year over year, Ahern says that supply-chain issues can derail any contractor’s momentum.

“That [supply chain] obviously caught everyone off guard,” he says. “We were able to make adjustments with our vendors. We’re very proud of how everyone worked with our supply-chain vendors, because that’s a potentially contentious situation.”

The tiny homes Castle is building are 240 sq ft to 320 sq ft and are expected to serve as transitional housing.

Image courtesy of Castle Contracting

Although supply-chain delays, inflation and price increases all took a toll on Midwest specialty contractors over the last year, Ahern says his company still sees opportunities in the market.

He says communicating challenges to customers and getting them to feel confident about how they will be addressed is key to success.

“We certainly pay close attention to these external factors,” says Ahern. “But at the end of the day we just keep in touch with the customer.”

Despite the challenges, he expects business to increase in 2022.

Post a comment to this article

Report Abusive Comment