Recreation Pier at the Wharf

Washington, D.C.

Best Project

Owner: Wharf District Master Development LLC

Lead Design Firm: Michael Vergason Landscape Architects Ltd.

General Contractor: Cianbro

Structural Engineer/Building Architect: Perkins Eastman DC

Marine Engineer: Moffatt & Nichol

Subcontractors: Bellingham Marine (Floating Dock); Biohabitats (Floating Wetlands); Colombo Construction Corp. (Sculpture); Genesis Steel Service (Rebar); J.F. Brinker & Sons Inc. (Pier Kiosk); K&B Plumbing

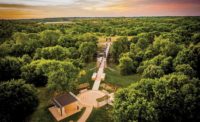

Recreation Pier, coupled with the adjacent 7th Street Park, forms a new community connection with the water. Extending more than 400 ft into the Washington Channel, the 21,000-sq-ft, fixed-deck pier structure is built atop nearly 100 18-in., variably spaced pipe piles topped with 35 precast pile caps and more than 90 customized curved precast concrete slabs.

A lower 2,500-sq-ft, curved post-tensioned floating dock doubles as a new kayak launch and a landing area for a jitney boat to East Potomac Park.

“The pier is a great gift to the public,” wrote one judge, who also called the project’s design “fluid” and “organic.”

The Recreation Pier’s configuration was designed to arc and dip softly at its midpoint toward the water, before rising at its terminus, creating multiple vantage points and varied opportunities for engaging with the water, the team said. The varied elevations and curvature left no room for error in the shape or positioning of substructure components.

Team-wide collaboration was essential to help the scheduled nine-month project recover quickly from a three-week start-up delay. Input from geotechnical and structural engineers made it possible to maximize pile capacity while minimizing length. A highly effective pile-driving approval and execution process also maximized the flow of the work. That enabled the project to gradually gain time and cost savings that the owner could reinvest in architectural features. By the time pile-driving was completed, the project was surpassing originally scheduled milestones and on track for completion ahead of schedule and under budget.

“Teamwork optimized the design and schedule,” another judge wrote.

Prefabricated and painted in Massachusetts, the concrete slabs were barged to Washington, D.C., for seamless assembly on the pier structure, precisely matching the specified elevations and curvature. Horizontal and vertical surfaces are wrapped with a highly durable, sustainable wood product that offers the aesthetics and performance of the best tropical hardwood, according to the project team. The material, secured to the pier with hidden fasteners, requires minimal maintenance, helping to reduce long-term upkeep costs.

The team says an innovative approach to installation made it possible to bend the material around the cantilevered, curved belvedere overlook at the end of the main pier, creating a sloped area down the structure’s center and enhancing the pier’s already striking aesthetic.

An ornamental guardrail composed of stainless-steel mesh infill panels was hand-sewn on site to ensure an exact fit and topped with an elliptical rail. Other features include a custom steel shade structure constructed of 2-in.-dia piping as well as benches, swings and floating wetlands. Punctuating the pier’s belvedere area is an 11-ft-tall, custom stainless-steel sculpture with a natural gas-fueled flame.

The pier remains a showpiece after dark, thanks to a unique lighting package with 10 different lighting zones and a strategically placed electrical network that connects the lights to state-of-the-art control system located in a nearby custom-built kiosk.

Related Article: ENR MidAtlantic's 2018 Best Projects: Region’s Top Work Sets High Bar

Post a comment to this article

Report Abusive Comment