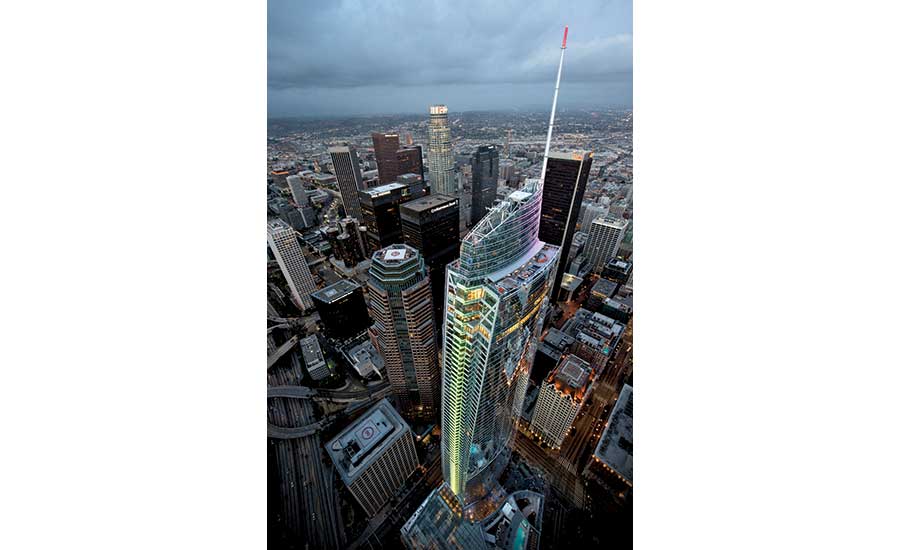

Wilshire Grand Center

Los Angeles

Best Project

Owner: Korean Airlines

Lead Design Firm: AC Martin Partners

General Contractor: Turner Construction Co.

Civil Engineer: Breen Engineering

Structural Engineer: Brandow & Johnston

Steel: Schuff Steel

Structural Concrete: Conco

From its record-breaking concrete foundation to its signature sail-shaped roof, the 73-story Wilshire Grand Center started a new era for downtown Los Angeles skyscrapers. At 1,100 ft, the mixed-use tower is the tallest structure in the city. It has 900 hotel rooms and 400,000 sq ft of office space.

Construction began with the floor-by-floor demolition of the 1.2-million-sq-ft historic Wilshire Grand Hotel, built in the 1950s. Heavy pedestrian and vehicle traffic packs the dense neighborhood around the site, complicating work. The operational MTA Subway Red Line is 5 ft from the property line, creating complications for below-grade demolition tasks.

Crews placed the tower’s massive concrete mat slab foundation during an 18-hour “grand pour,” installing nearly 7 million lb of reinforced steel prior to pouring 2 million cu yd of concrete. More than 2,000 concrete trucks served the site during the pour, hauling concrete from eight batch plants.

“It took 12 months to plan,” says Brendan Murphy, vice president and operations manager at general contractor Turner Construction Co. “Structurally, we had to do it all in one placement, based on the geometry and the height of the structure.” Workers also placed around 5,000 ft of coolant piping during the pour to control how the concrete solidified.

The project team used three-dimensional and four-dimensional modeling during demolition and construction. When working around the MTA subway tunnel, the team modeled all shoring and tiebacks to ensure construction would not impact the subway line.

The team’s plans for the tower’s sail-shaped roof prompted a discussion with city officials since Los Angeles building codes require a flat helipad on roofs to allow emergency access. Project architects and engineers designed a smaller, modified helicopter pad that wouldn’t compromise the sail shape.

“It’s designed so the helicopter could hover above the building and put one of the skids on the tactical approach pad,” Murphy says. “Then someone can access the roof and go into the building in case of an emergency.”

Back to "ENR California Best Projects 2018: Region's Best Work Shines With Creativity"

Post a comment to this article

Report Abusive Comment