| Sockets with a positive impact Rugged bolting, fastening and anchoring applications are tackled by the high-strength Hilti Impact Sockets. Available in standard and deep confi gurations, Hilti’s new lineup of Impact Sockets is built for quick attachment and durable performance. Hilti Impact Sockets are constructed of hardened alloy steel for long-lasting service. Use of the hardened alloy steel allows the socket walls to be thin for use in tight spaces, yet strong enough to handle diffi cult torque and working conditions. The quick attachment time of the new Hilti Impact Socket portfolio improves productivity. Two beveled detent holes allow the quick attachment and increase attachment accuracy. The Impact Socket line can be used for anchoring HUS and HCA coil, fastening lag bolts and bolting grades 2, 5 and 8 stainless steel or galvanized bolts. Along with the thin wall construction, the option of using deep sockets also aids in tight-space applications. All Hilti Impact Sockets can be purchased individually to meet specific needs or purchased in varying kits with the Hilti SIW 144-A Impact Wrench. Currently, two of the most popular standard sizes, 1 / 2 ” and 9/16”, are being packaged with the SIW 144-A at no additional cost, providing extra value for mechanical, electrical, building and other contractors using the SIW 144-A wrench. For more information on Hilti Impact Sockets, please contact Hilti at 800-879-8000 or visit www.us.hilti.com |

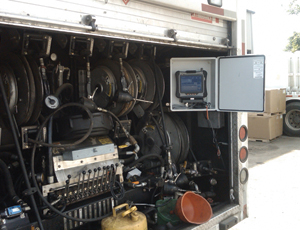

| Spectrum Equipment Service System Dexter + Chaney recently introduced the Spectrum Equipment Service System, which electronically collects asset-management data for a construction company’s heavy equipment, including equipment hours, fuel usage and maintenance. “Spectrum Equipment Service System is an answer to the critical problem of recording accurate equipment hours,” said John Chaney, Dexter + Chaney president and co-founder. “It eliminates the time and hassle of manual data collection that results in inaccurate and unreliable asset management information. By gathering equipment hours electronically, the company can seize control of operating costs, generate a higher return on its equipment investment and increase overall company profitability.” The system simplifies equipment servicing for mechanics and fuel truck drivers since they’re not required to climb into individual pieces of equipment to read the hour meter and write down the current reading. There’s also no need to keep a detailed log recording fuel for each piece of equipment. Instead, Spectrum automatically captures operating hours and fuel, thus saving time and eliminating errors in the field. Office staff does not have to re-enter long lists of hours logged and fuel used into a company’s equipment-management software. Chaney added that Spectrum alerts the fuel truck driver when preventive-maintenance tasks are due. It also records the maintenance activity when the fuel truck driver performs it. “Spectrum triggers maintenance activities by providing alerts and captures the equipment meter reading when each task is performed,” Chaney said. Spectrum Equipment Service System includes three main components: equipment monitor, field master touch screen device and fuel controller. The equipment monitor, a small device attached to each piece of machinery, records operating hours and idle hours and automatically relays that data to the field master each time the equipment is fueled or serviced. The field master—mounted in a fuel truck or service vehicle—electronically collects data from each piece of heavy equipment via wireless RF signal. The field master uses a built-in cellular modem to relay equipment hours, fuel usage, maintenance and other data to Dexter + Chaney’s Spectrum Construction Software. That gives the company easy access to equipment-related information in Spectrum for improved equipment costing and management. For information about Spectrum Equipment Service System and Spectrum Construction Software, contact Dexter + Chaney at 800-875-1400 or 206-364-1400; info@dexterchaney.com; www.dexterchaney.com. |

Post a comment to this article

Report Abusive Comment